SEAC SUB ENGLISH

17

DIAMOND /DIAMOND ICE REGULATORS

SECOND STAGE

Second stage with air balancing system which

reduces the initial breathing effort while pro-

viding a linear and constantly smooth breath-

ing. The system operation is based on a pneu-

matic piston working in close contact with the

spring, enabling the latter to work with a

lower load force (consequent light breathing)

ensuring a perfect seal of the air flow during

the breathing out phase.

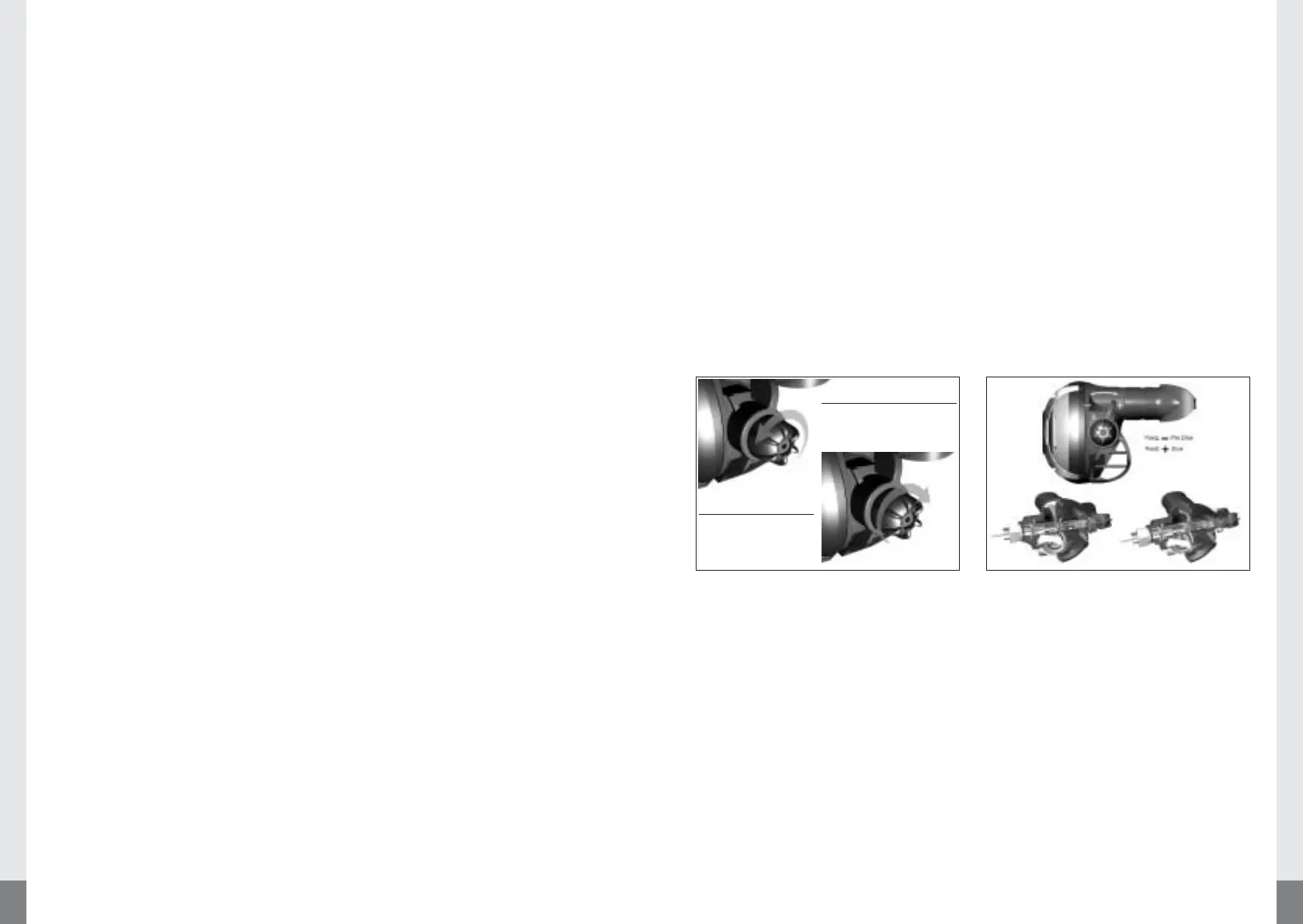

By actuating the knob located on the left of the

regulator (see Figure A-B) you can regulate the

breathing softness according to your breathing

demand and to the diving conditions.

By rotating it anticlockwise you will get the

maximum breathing softness and by rotating

it clockwise you will gradually reach a stan-

dard breathing flow. This second stage conse-

quently allows individualizing the breathing

demand as a function of the dive require-

ments and type.

The operation is of the “Downstream” type.

This system allows for low air consumption by

reducing air waste, as it perfectly meets the

breathing demand.

This means that the air flow delivery is per-

fectly controlled by the diver’s breathing ac-

tion: a normal breathing action produces a

light air flow, while heavy breathing due to

fatigue or deep diving produces a free air

flow, also increased by the Venturi effect.

In addition, this system also provides safety

margins in case of first stage overpressure:

should the intermediate pressure supplied by

the first stage suddenly increase, the second

stage would continue to work, thus releasing

excess pressure and enabling the diver to

breathe.

The control of the DIVE and PRE-DIVE mecha-

nism allows to insert the Venturi effect. This

system is placed around the knob regulating

the breathing effort reduction system.

By actuating this mechanism placed to the

left of the second stage you can insert the

Venturi effect and consequently increase air

delivery.

By turning the lever towards the outside you

reach the “PRE-DIVE” position, while by turn-

ing the lever towards the diver you reach the

“DIVE” position. (see Figure C)

The “PRE-DIVE” position is recommended to

prevent accidental delivery when the regula-

tor is under pressure but not used, while the

“DIVE” position is recommended during the

dive.

Warning! Move the lever to “PRE-DIVE” only

when the regulator is not used, and rotate it

to “DIVE” before dive start.

The main body is made of synthetic resin,

which is highly resistant to impacts, abrasions,

ultraviolet rays and chemical agents. Di-

aphragms are made of medical grade silicone,

while nitrile rubber O-rings are of different

hardness (Shore) as a function of their appli-

cations. Chrome-plated brass and stainless

steel internal components. Black anallergic

silicone mouthpiece.

The nut placed on the hose end was especial-

ly designed with slightly marked lines for cos-

metic purposes, so as to give the Diamond

regulator a professional and captivating look.

The hose is of the standard type (770 mm

length and 3/8” thread).

SEAC SUB ENGLISH

16

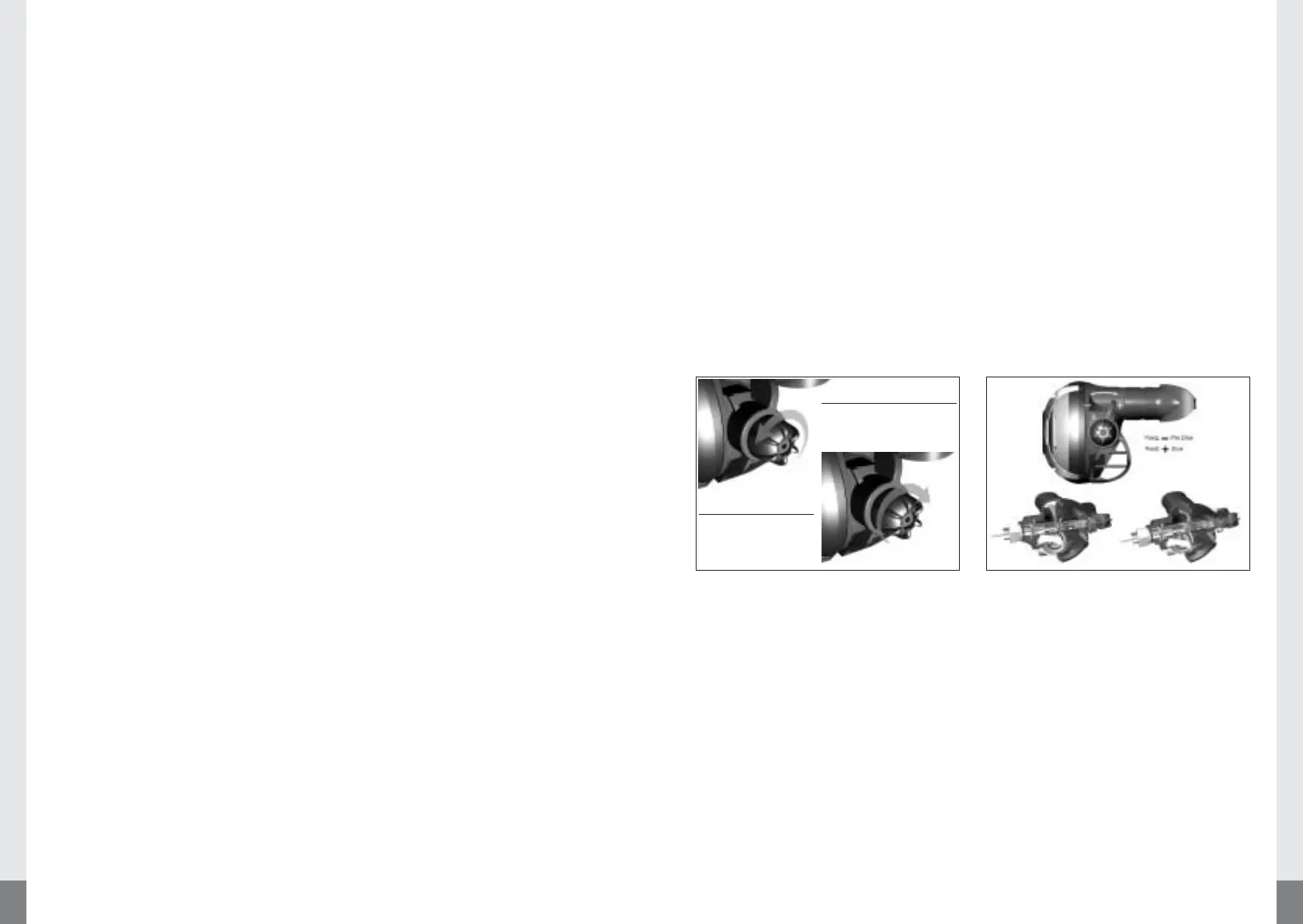

This first stage combines very high performance

with an extremely compact and round shape.

Operation is ensured by a balanced di-

aphragm system which keeps a constant in-

termediate pressure with reference to both

tank pressure and depth. In addition, the di-

aphragm completely separates the regulator

core from the external environment, ensuring

total reliability over a long series of dives.

It is cast as a single block of copper-plated

brass, subsequently nickel- and chrome-plat-

ed. Internal components are in chrome-plated

brass with music-wire springs and nitrile-rub-

ber seals. Particular care was given to the sep-

arating diaphragm, made of a special rubber

which remains unchanged and is resistant to

low temperatures.

Four low-pressure ports, provided with 3/8”

thread, supply a constant pressure of 9.8 bars;

all ports are considered preferential, as they

are implemented on the same axis; in addi-

tion, two of them are positioned at 30° with

regard to the first stage body, so as to make

the correct bending of the valves inserted

easier; the most important components, such

as the main regulator (on the right) and the

jacket or dry diving suit hose (on the left),

shall be connected to these two ports.

In decentralized position there are two high-

pressure ports (one to the right and the other

to the left) with 7/16” thread and inner hole

having a 0.20 mm. diameter; a diving pres-

sure-gauge may be connected to these high-

pressure ports, to check the internal pressure

of the cylinder used, by means of a hose with

7/16” thread male connection.

Warning!

Use only CE certified pressure gauges provid-

ed with standard thread. Do not use any type

of adapter between the first stage and the

high pressure hose connection.

The DIAMOND first stage has been designed

to operate with cylinder working pressures up

to 300 bar. For pressure exceeding 230 bar it

is advisable to use the version provided with

the 300 bar thread connection (THREAD CON-

NECTION ISO 12209-2/3.2; 300 BAR) imple-

mented in our model DIAMOND ICE

The DIAMOND first stage is implemented in

the following versions:

International YOKE connection

(ISO 12209-1 230 BAR)

THREAD connection

(ISO 12209-2/3.5; 230 BAR)

DIAMOND ICE REGULATOR

FIRST STAGE

First stage has the same characteristics as the

DIAMOND version, but with the addition of

the innovative ANTIFREEZE DRY SYSTEM.

This system enables diving under extreme

temperature conditions, while keeping oper-

ating characteristics unchanged.

An antifreeze silicone separating diaphragm,

placed at the end of the first stage insulates

the regulator mechanics from the outside,

while transmitting through a simple and

functional mechanism, the water external

pressure needed for proper and constant bal-

ancing of the first stage under any pressure

and diving conditions.

This version is recommended for dives in cold

waters or mountain lakes where the water

may reach temperatures nearing zero.

The DIAMOND ICE version First stage is imple-

mented in the following versions:

International Yoke connection

(ISO 12209-1 230 BAR)

Thread connection

(ISO 12209-2/3.5; 230 BAR)

Thread connection

(ISO 12209-2/3.2; 300 BAR)

Warning!

To use the YOKE connection (ISO 12209-1 230

bar) or the THREAD connection (ISO 12209-

2/3.5; 230 bar), you must use a cylinder having

valves fitted with the relevant connections.

We recommend you to keep a common 8 mm

Allen wrench within reach, so that you may

operate on the valves, if needed, to obtain

the right connection. Please note that (the

300 bar THREAD connection) (ISO 12209-

2/3.2; 300 bar), only valves with the relevant

connection should be used.

EROGATORI DIAMOND, DIAMOND ICE, DIAMOND OCTO.

DIAMOND REGULATOR - FIRST STAGE

Figure A-B Figure C

DIVE PRE-DIVE

A

MANOPOLINA SVITATA

(SENSO ANTIORARIO)

RIDUZIONE SFORZO

INSPIRATORIO

B

MANOPOLINA AVVITATA

(SENSO ORARIO)

SFORZO INSPIRATORIO

NORMALE

Loading...

Loading...