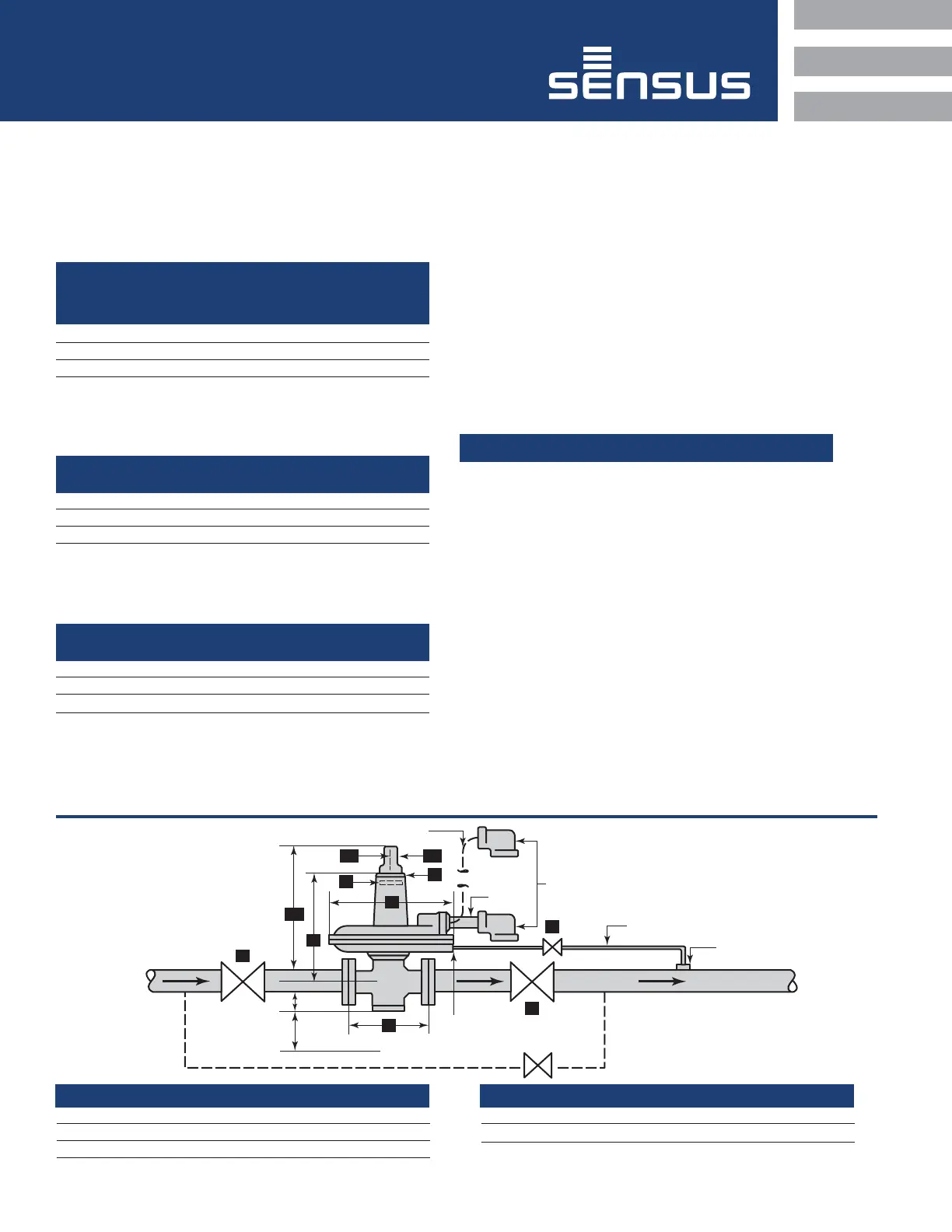

3a 1a

3

D1

C

Inlet

Minimum

Service Space

D

4"

8"

F

Bypass (if required)

Remote Vent (if required)

1" NPT

B

A

Control Line

Connection

Control Line

1/4" NPT

Outlet

Vent Cap

3

E

Model D D1 E

461-12S 13-1/4" – 14"

461-8S – 18-3/8" 10-3/16"

461-S (12") – 19-1/2" 14-1/4"

461-S (8-1/2") – 19-1/2" 11"

Regulator Body Type F (Face to Face)

Screwed 6-1/2"

Flanged ANSI 125 FF 10"

Flanged ANSI 250 FF 10-1/2"

2

Maximum

Working

Regulator Body Pressure

Body Type Materials of Body

2" Screwed only Cast Iron 250 psi

Flanged ANSI 125 Cast Iron 175 psi*

Flanged ANSI 250 Ductile Iron 575 psi*

Flanged ANSI 300 Cast Steel 720 psi*

Maximum Inlet Pressures

Regulator Models 461-S, 461-8S, and 461-12S are excellent

general purpose gas pressure regulators for intermediate and

larger loads. Use them for natural gas, air, dry CO

2

, propane,

butane and other gases.

*Carefully note the following exceptions to the above,

based on diaphragm size:

Diaphragm Diaphragm Maximum Inlet

Size ID Case Material Pressure

12” Cast Iron 100 psi

8-1/2” Cast Iron 175 psi

12” Aluminum 100 psi

8” Aluminum 175 psi

Valve material selection is limited by inlet pressure and

differential:

Valve Maximum Inlet Maximum Pressure

Material Pressure Rating Differential Rating

Buna-N 575 psi 250 psi

Poly-U Red 720 psi 400 psi

Poly-U Tan 1200 psi 600 psi

Typical Arrangement

and Dimensions

(Indoor or Outdoor Installation)

Installation and Start-Up

1 Thoroughly purge inlet piping to remove dirt and debris that could

damage the regulator or impair its operation. If this cannot be

done, a filter or strainer should be installed ahead of the regulator.

(see bulletin RDS-1498, Regulator Pressure Ratings).

Make certain that inside of the regulator and piping are free

of dirt, foreign matter, and other debris.

2 Install the regulator. Make certain flow through the regulator is

in the correct direction. High pressure connects to the inlet

side. Be sure that shipping screens or covers, if used, are

removed.

On flanges, tighten bolts evenly. On screwed connections,

apply pipe dope to male threads only. Where required,

the regulator may be inverted.

CAUTION

It is the user's responsibility to assure that all regulator vents

and/or vent lines exhaust to a non-hazardous location away from

any potential sources of ignition. Where vent lines are used,

it is the user's responsibility to assure that each regulator is

individually vented and that common vent lines are not used.

3 The vent connection is an escape path for flammable gas and

it must be located and/or piped so that potential discharge

occurs in a safe area away from buildings, open flames,

collection areas, arcing devices, etc.

Regulators that are installed indoors, or in a non-vented area

must be vented to the outside. Simply run vent piping from

the regulator vent connection to a non-hazardous location

on the outside away from any potential sources of ignition.

The vent piping must be connection size or larger and piped

to a safe area.

The outlet of the vent piping must allow for the free and

unobstructed passage of air and gas, and must be protected

against the potentials listed in instructions.

Installation and Maintenance Instructions

Model 461-S, 461-8S, and 461-12S Regulator

Loading...

Loading...