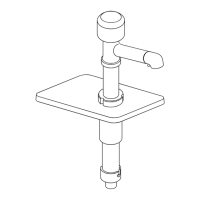

PUMP DISASSEMBLY

BEFORE FIRST USE AND AFTER USE DAILY, DISASSEMBLE

AND CLEAN PUMP.

1 PUMP OUT ALL (IF ANY) REMAINING FOOD PRODUCT

FROM INSIDE PUMP BODY.

2 WASH AND RINSE OFF OUTSIDE OF PUMP BODY.

3 FLUSH AND RINSE ALL INSIDE AND OUTSIDE

SURFACES OF PUMP THOROUGHLY WITH HOT

WATER.

• Place lower end of pump into container of hot water

and operate pump until all (if any) remaining product

is expelled and only hot water ows from discharge

tube. Then remove pump from container of water to

disassemble.

•

Use a container to col

lect small parts of pump to

prevent any loss.

4 REMOVE PLUNGER ASSEMBLY AND LID FROM

PUMP BODY BY TURNING LOCKING COLLAR

COUNTERCLOCKWISE.

5 REMOVE SPRING FROM PUMP BODY.

6 REMOVE CYLINDER FROM CONNECTOR. PUSH

CYLINDER INTO CONNECTOR TO COMPRESS

BALL VALVE WHILE ROTATING CYLINDER

COUNTERCLOCKWISE. ROTATE CYLINDER TO

RELEASE PINS FROM SLOTS ON CONNECTOR.

7 REMOVE BALL VALVE FROM INSIDE CONNECTOR.

8 REMOVE DISCHARGE TUBE BODY FROM

PISTON BY ROTATING DISCHARGE TUBE BODY

COUNTERCLOCKWISE.

•

B

e prepared for ball valve to fall loose when

removing discharge tube body from piston.

9 REMOVE BALL VALVE FROM PISTON, IF REMAINING

ON END OF PISTON.

J REMOVE LOCKING COLLAR AND GAGING COLLAR(S),

IF USED, FROM PISTON BY SLIDING THEM OFF.

K REMOVE SEAL FROM END OF PISTON BY ROTATING

AND PULLING OFF OF LIP ON PISTON.

L REMOVE KNOB FROM DISCHARGE TUBE BODY BY

PULLING KNOB AT AN ANGLE UNTIL KNOB FLANGES

RELEASE FROM LIP ON DISCHARGE TUBE BOD

y.

M REMOVE DISCHARGE FITTING FROM DISCHARGE

TUBE BY RELEASING FITTING LOOP AND PULLING

FITTING AWAY FROM DISCHARGE TUBE.

•

DO NO

T USE FITTING LOOP ON DISCHARGE

FITTING AS A PULL.

PUMP ASSEMBLY

BEFORE FIRST USE AND AFTER USE DAILY, DISASSEMBLE

AND CLEAN PUMP.

1 INSTALL DISCHARGE FITTING INTO DISCHARGE

TUBE. SECURE DISCHARGE FITTING TO TUBE BY

HOOKING FITTING LOOP AROUND PROJECTION ON

END OF DISCHARGE TUBE.

2 INSTALL KNOB ONTO TOP OF DISCHARGE TUBE BODY

BY PUSHING TOGETHER UNTIL KNOB SNAPS ONTO

LIP OF DISCHARGE TUBE BODY.

3 INSTALL SEAL ONTO BOTTOM OF PISTON. SEAL IS

SECURE WHEN IT SNAPS ONTO LIP AROUND BOTTOM

OF PISTON.

4 INSTALL GAGING COLLAR(S), IF NEEDED, AND

LOCKING COLLAR ONTO THREADED END OF PISTON

BY SLIDING THEM ON. POSITION LOCKING COLLAR

WITH THREADING INSIDE LOCKING COLLAR FACING

SEAL AT BOTTOM OF PISTON.

5 INSTALL ONE OF THE BALL VALVES WITH BALL SIDE

SEATED DOWN INTO OPENING IN TOP OF PISTON.

6 INSTALL BOTTOM OF DISCHARGE TUBE BODY ONTO

THREADED TOP OF PISTON WITH BALL VALVE IN

POSITION RESTING ON TOP OF PISTON. ROTATE

DISCHARGE TUBE BODY CLOCKWISE UNTIL SECURE

WITH PUMP TUBE ASSEMBLY.

7 INSTALL THE OTHER BALL VALVE WITH THE BALL

SIDE SEATED DOWN INTO OPENING INSIDE

CONNECTOR.

8 INSTALL BOTTOM END OF PUMP BODY, WITH PINS,

INTO CONNECTOR WITH BALL VALVE IN POSITION

RESTING INSIDE CONNECTOR. COMPRESS BALL

VALVE SLIGHTLY AND ROTATE PUMP BODY INTO

CONNECTOR UNTIL PINS SECURE INTO SLOTS IN

CONNECTOR.

9 INSTALL SPRING INTO PUMP BODY.

J INSTALL LID ONTO PUMP BODY BY ALIGNING LARGE

HOLE IN LID TO REST ON THREADED LIP OF PUMP

BODY ASSEMBLY.

K INSTALL PLUNGER ASSEMBLY INTO PUMP BODY

ASSEMBLY. COMPRESS PUMP AND ROTATE UNTIL

FLATS ON PISTON ALIGN INTO POSITION WITH

FLATS INSIDE CYLINDER.

L WHILE COMPRESSING PUMP, ROTATE LOCKING

COLLAR CLOCKWISE TO SECURE ONTO THREADING

OF CYLINDER.

M IF SUCTION TUBE IS INCLUDED, INSTALL ONTO

BOTTOM OF CONNECTOR. THE SUCTION TUBE MAY

BE CUT WITH SCISSORS TO THE NEEDED LENGTH.

PUMP CLEANING

BEFORE FIRST USE AND AFTER USE DAILY OR

REGULARLY, DISASSEMBLE AND CLEAN PARTS.

FOR SAFE AND PROPER CARE, AND TO PREVENT

CORROSION, OF PARTS, IT IS IMPORTANT TO

CLEAN, RINSE, SANITIZE, AND DRY PARTS DAILY OR

REGULARLY. FAILURE TO COMPLY WITH ANY OF THESE

INSTRUCTIONS MAY VOID UNIT WARRANTY.

1 SEE PUMP DISASSEMBLY.

2 WASH CLEAN ALL PARTS WITH DISHWASHING

DETERGENT AND HOT WATER.

•

Wash small parts in a pan or other container to

prevent part loss.

•

Scrub with supplied brushes to clean all

conned areas. Maintain a clean and efcient

pump by using the brushes supplied with

pump to prevent product build up inside pump.

•

Do not use scr

apers, steel pads, steel wool, or other

cleaning tools that can scratch surfaces.

• Mildly abrasive NYLON or brass brush may be used

to remove any stubborn food or mineral deposits on

interior surfaces of unit.

•

Do not use abr

asive cleansers.

• Do not use caustic cleansers.

•

Do not use cleansing agents wi

th high concentrations

of acid, alkaline or chlorine.

•

Do not use ammonia based cleansers.

3 FULLY RINSE ALL WASHED PARTS THOROUGHLY

WITH CLEAR WATER.

•

T

o prevent corrosion on parts, it is important to

thoroughly and fully rinse washed parts.

4 DRY ALL PARTS WITH A CLEAN SOFT CLOTH.

•

V

arious elements and minerals, such as chlorides in

tap water, can accumulate on stainless steel parts

and create corrosion.

• To prevent corrosion on stainless steel parts, it is

important to thoroughly and fully dry with a clean

soft cloth regularly.

5 SANITIZE ALL PARTS FOLLOWING LOCAL

SANITIZATION REQUIREMENTS. ALL PARTS IN

CONTACT WITH FOOD MUST BE SANITIZED.

• Allow parts to fully air dry after sanitization.

•

Dish

washer safe.

Loading...

Loading...