15

142 x 208 mm

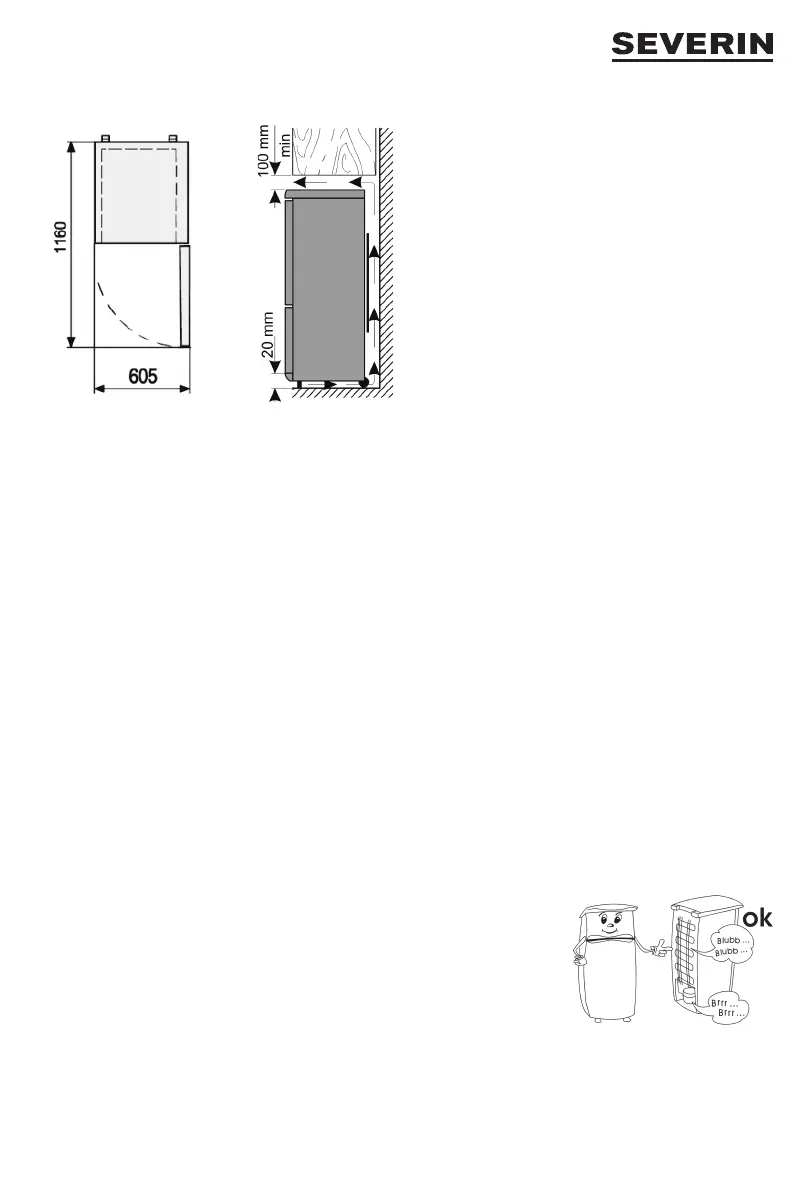

Set-up dimensions Ventilation

The heated air

around the rear of

the unit must be able

to circulate freely.

Therefore, ensure that

the air circulation is

not obstructed.

Warning: Take special care that the ventilation

openings in the upper part of the rear panel are not

blocked or obstructed.

Temperature control

∙ The unit is activated by connecting it to the mains. It is

only switched off completely when the plug is removed

from the wall socket.

∙ The green mains indicator light shows that the unit is

connected to the mains.

∙ The temperature in the refrigerator cabinet can be

adjusted by setting the temperature control (0-5).

Turning the control clockwise will decrease the

temperature, while turning it anti-clockwise will increase

it.

∙ The temperature can be set within a 0 to 10°C range.

∙ The temperature in the cabinet largely depends on

factors such as the ambient temperature, the setting and

the number of bottles stored.

∙ We recommend using a thermometer to check the actual

temperature inside the cabinet and make adjustments

as necessary.

∙ Always ensure that the door is properly closed and that

the seal is not obstructed by bottles stored inside the

cabinet.

∙ Following a power interruption, or if the unit has been

switched off on purpose, it may take 3 to 5 minutes

before it switches on again.

∙ Note: With the temperature control in position ‘0’,

only the compressor is switched off, while the fan is

still running.

Interior lighting

∙ The interior light can be switched on by means of the

separate On/Off switch.

∙ Caution: Do not remove the cover of the interior LED

light. If there should be any malfunction, please contact

the customer service for assistance.

Cleaning and defrosting

During operation, you may notice a build-up of frost around

the integral evaporator sealed into the rear of the inside

cabinet. This layer of frost will start melting when the

compressor is not working. Through a system of hoses,

the melt-water drains into the collection tray below the

compressor, where it will be absorbed into the surrounding

air.

∙ The unit does not therefore require de-frosting, but only

proper cleaning.

∙ To enable the melt-water to drain freely, always ensure

that the channel and discharge opening in the cabinet

are free of any blockage.

∙ Any water collecting in the bottom should be removed.

∙ Always remove the plug from the wall socket before

cleaning.

∙ Do not pour water over or inside the unit.

∙ Do not use aggressive cleaning detergents or those

containing alcohol. Also, do not use electrical devices

such as steam cleaning devices for defrosting or

cleaning.

∙ For frequent cleaning we recommend the use of warm

water with some mild detergent.

∙ The cabinet should be cleaned once a month.

∙ Any accessories should be cleaned separately with soapy

water. Do not put them in a dishwasher.

∙ After cleaning, thoroughly clean all surfaces with fresh

water before wiping them completely dry. When re-

inserting the plug into the wall socket ensure that you

have dry hands.

∙ To save energy and to ensure optimum performance, the

compressor (at the rear) should be carefully cleaned at

least twice a year, with a brush or a vacuum cleaner.

Trouble-shooting

Certain typical sounds can be heard when the appliance is

switched on. These sounds are caused by:

∙ the electric

motor within

the compressor

assembly; during

compressor

start-up the sound

level will be slightly

higher for a short

time.

∙ the cooling agent owing through the circuit.

The following table lists possible malfunctions, their

probable causes and solutions. In the event of operational

problems, check rst whether a solution can be found

Loading...

Loading...