R-410A Refrigerant Overview

The U.S. Clean Air Act of 1990 and the Montreal

Protocol call for the phaseout of HCFC-22 (commonly

known as R-22). This has caused manufacturers to

replacement for the standard R-22 refrigerant.

The EPA is not mandating the use of R-410A. They

are mandating that R-22 can no longer be used in new

equipment in 2010, and production of R-22 will cease in

2020. Manufacturers must use alternative refrigerants,

and so far, most of them are choosing R-134A or R-410A.

However, R-407C is being used in many rooftop units and

other refrigerants as well, depending on the application.

The major difference between R-22 and R-410A is the

cantly higher pressures involved with using R-410A.

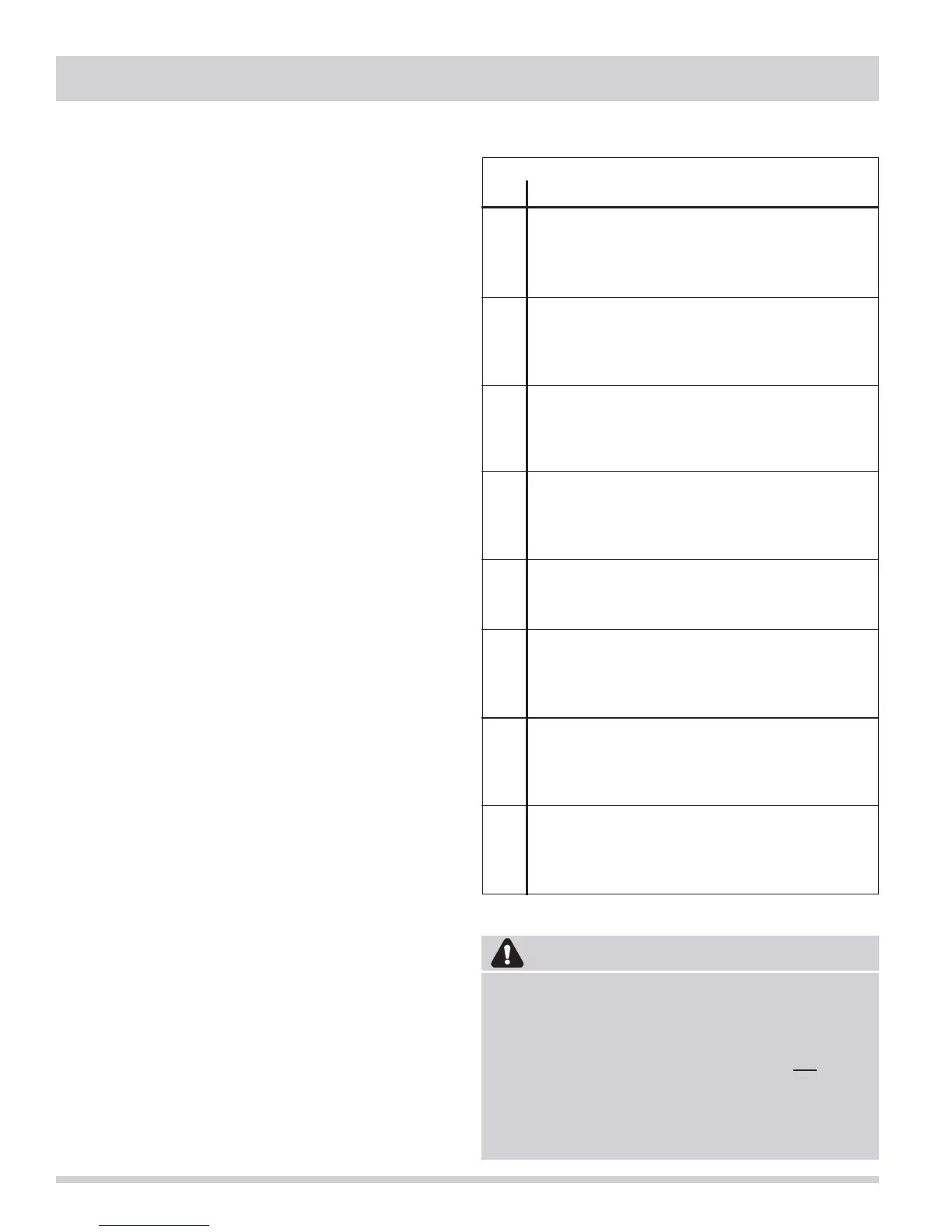

The pressure-temperature chart for R-410A compares

the pressures of R-410A versus R-22 (Figure 6-1). This

chart shows how high the pressures are within the sealed

system. In general, R-410A pressures are 1.8 times

higher than those of R-22.

It also is important to note that R-410A is not to be used

t applications and that only compressors that are

designed for R-410A refrigerant should be used. R-410A

refrigerant uses Polyol Ester oil, which is hygroscopic,

and can be irritating to skin, but it also improves heat

transfer. R-410A is a binary (two part), near-azeotropic

mixture, and is presently marketed under the brand

names of AZ-20, Puron, and Suva. The closer a blend

comes to being a true azeotrope, the less temperature

Temperature glide occurs when a refrigerant has a range

of temperature in which it will boil and condense at one

pressure. The lower the temperature the less chance it

will fractionate. R-410A has less then 0.3 degrees of

temperature glide. R-407C has a high temperature glide

and may fractionate into its component refrigerants, but

it is still a good replacement for R-22. Some refrigerants

ammable when fractionated. This

different leakage rate is caused from the different partial

pressure of each constituent. To avoid fractionation,

liquid charging should be done whenever possible and

should be transferred from the refrigerant tank as liquid.

When adding liquid refrigerant into the low side of the

compressor, make sure the liquid is throttled to avoid

Pure and azeotropic refrigerants have no fractionation

or temperature glide. Although some R-22 indoor coils

meet the UL approved design and service pressure

rating of 235 psig, always con

manufacturer before using R-22 indoor coils with R-410A.

R-22 Pressure Pressure R-410A

Refrigerant Vapor Pressures

R-410A is incompatible with R-22 refrigerant. R-410A is

used at much higher operating pressures than R-22

and other newer refrigerants.

Filter-driers used with R-22 refrigerants are not

compatible with an R-410A sealed system. When

replacing a filter-drier in an R-410A system, make sure

the replacement filter drier is specifically designed for

Loading...

Loading...