Refrigerant Recovery Systems

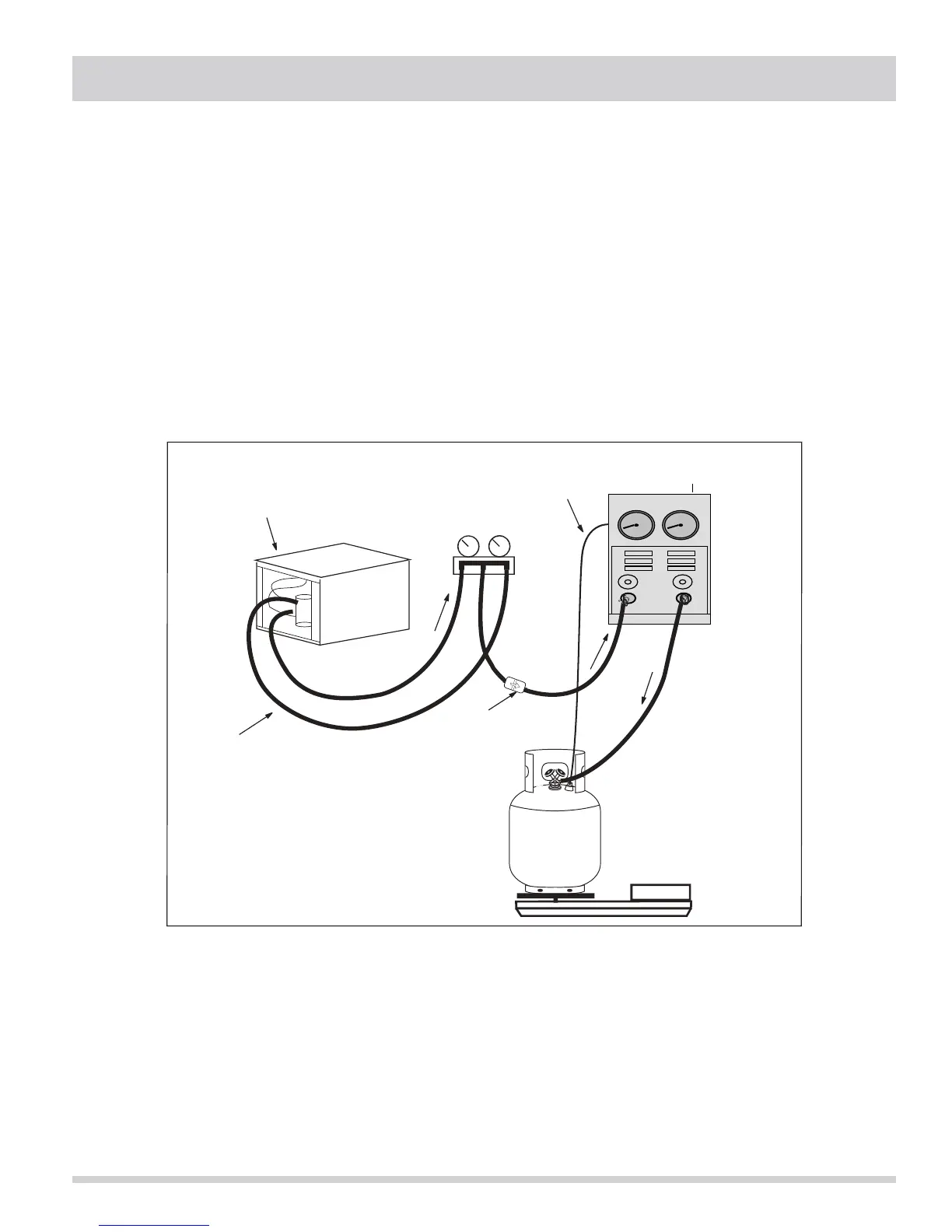

Efficient recovery of refrigerant from equipment or containers requires evacuation at the end of the recovery cycle.

Suction lines to a recovery compressor should be periodically checked for leaks to prevent compressing air into the

recovery refrigerant tank during evacuation. In addition, the recovery refrigerant tank pressure should be monitored,

and evacuation stopped in the event of a rapid pressure rise indicating the presence of noncondensable air. The

recovery refrigerant tank contents should then be analyzed for NAG, and the recovery system leak checked if air is

present. DO NOT continue to evacuate a refrigeration system that has a major leak.

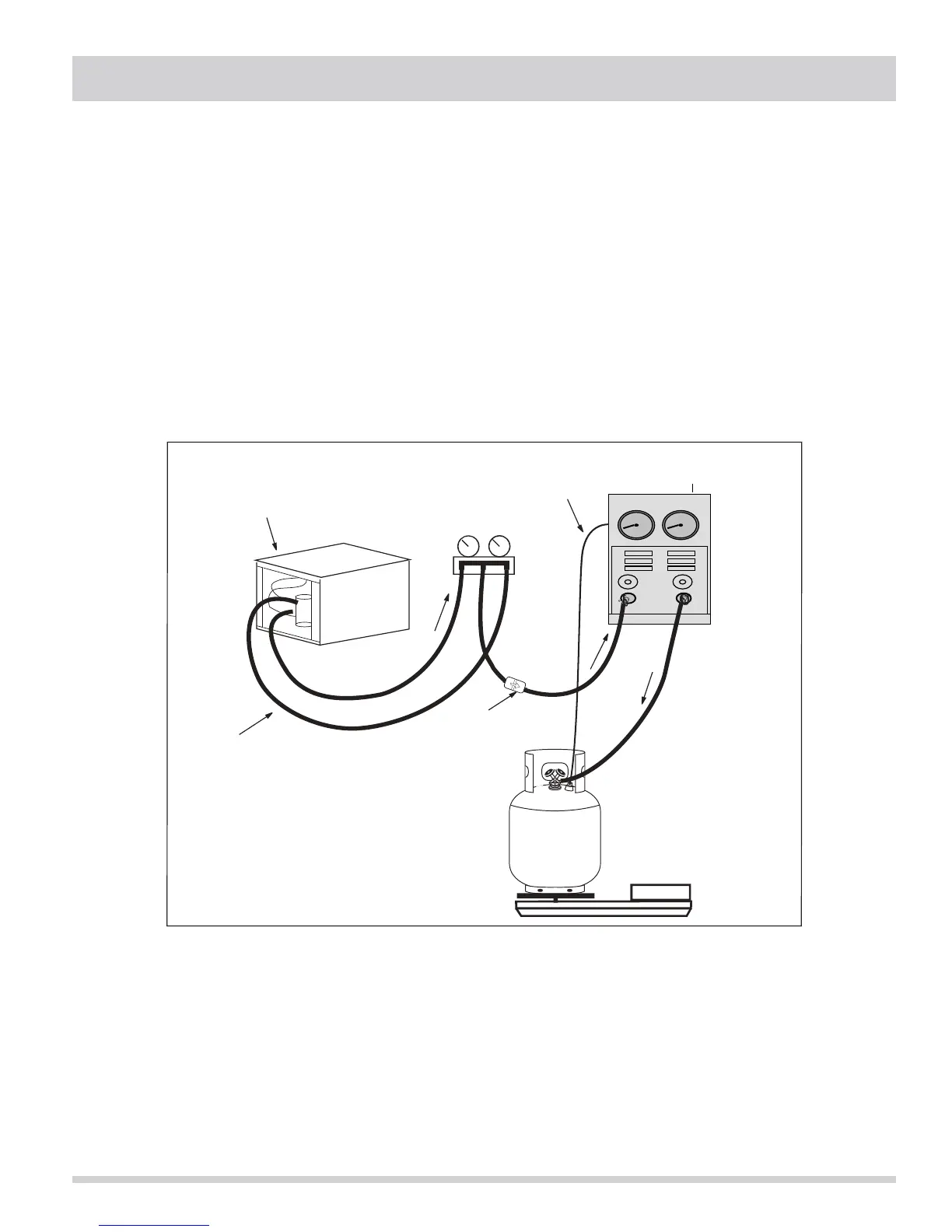

Even though refrigerant properties are different, the basic

recovery process is the same for R-410A and R-22.

R-410A is much more dense than R-22 and has a higher vapor pressure making it more dif

hook-up and recovery instructions will vary from manufactur

er to manufacturer so be sure to read and understand all

of the operation instructions for the refrigerant recovery unit being used.

Quickly removes the liquid refrigerant, but you must change the hose connections to recover vapor refrigerant after all

of the liquid is removed. This method is not recommended unless

trying to recover more than 10 pounds of refrigerant.

Not all recovery equipment is capable of handling direct liquid r

ecovery. Check with the manufacturer of the recovery

nd out if the unit is capable and if there are any special instructions for direct liquid recovery.

This method is slower than liquid recovery, yet is the most common method used to recover refrigerant.

Ú®±³ ̸» Ø·¹¸ ß²¼ Ô±© Í·¼»

Loading...

Loading...