OPERATOR’S MANUAL

P 29 / 57

b. Lubrication of sliding surfaces of work table, saddle, base and gib :

( 20VSG, 20VGA, 20VHS, 20VHA ) ( 20VS, 20VA, 20VB, 20VC )

Position Lubricated Parts Lubricant Frequency Q’ty

( A ) Inlet

Sliding surface of work table,

saddle, Base Gib and feed

leadscrews

KUO KUANG R-68

ESSO FBIS K53

VACTRA 2

GULF WAY 52

SHELL TONNA 33

3-5 times daily by

pulling 3 times

each

Filled up to

upper

leveL

Fig.31

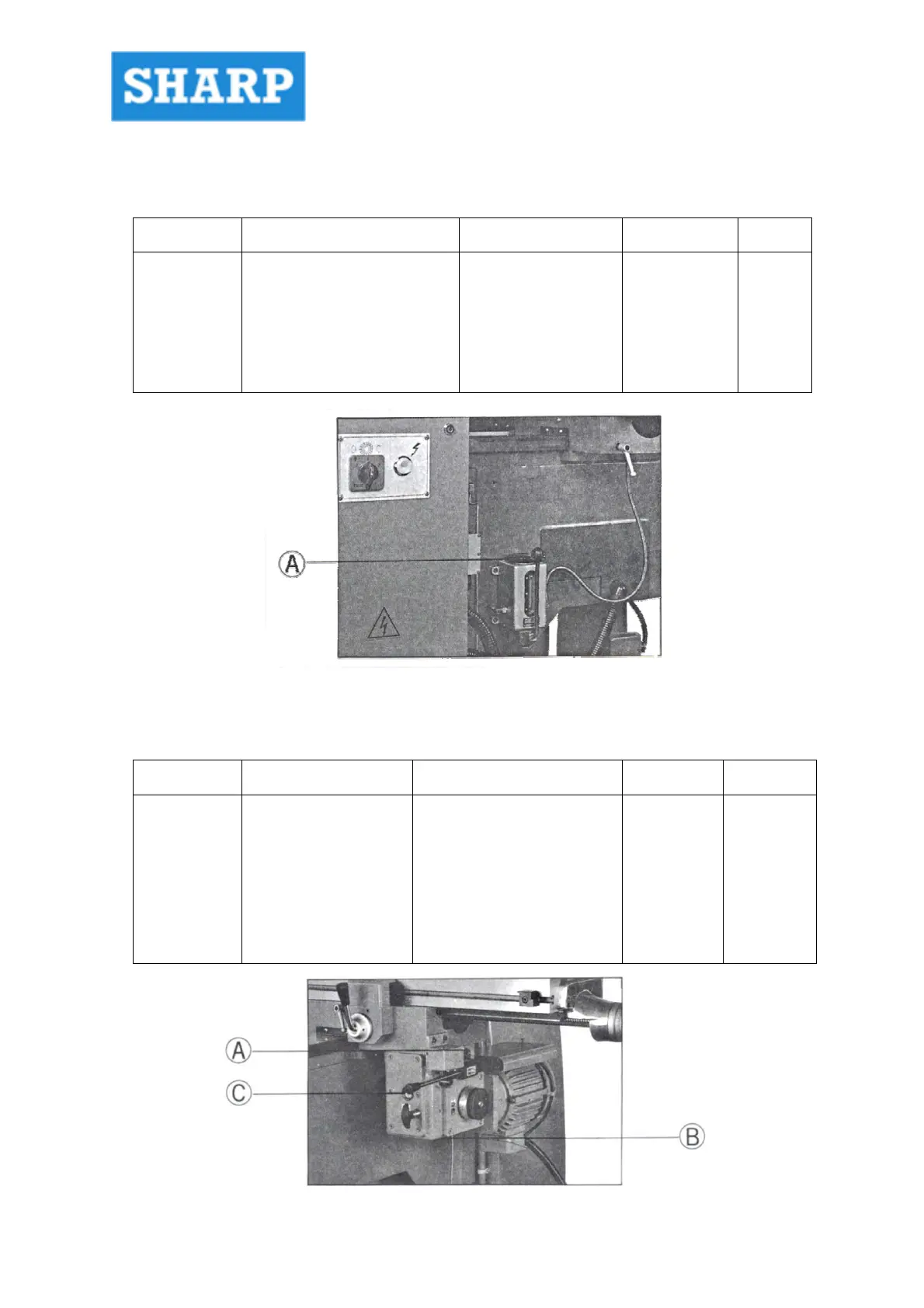

c. Gear Housing Lubrication (20VSG, 20VGA, 20VHS, 20VHA )

Position Lubricated Parts Lubricant Frequency Q’ty

( A ) Inlet

( B ) Outlet

Gears Inside

Gear Housing

KUO KUANG R-68

GULF WAY 52

VACTRA 2

ESSO FBIS K53

SHELL TONNA 33

HEAVY MEDIUM

First oil

change at 3

months after

installation

Then, every

other 6

months

Filled up to

between H-L

in oil window

(C) (1/2

height)

Fig.32

Loading...

Loading...