OPERATOR’S MANUAL

P 51 / 57

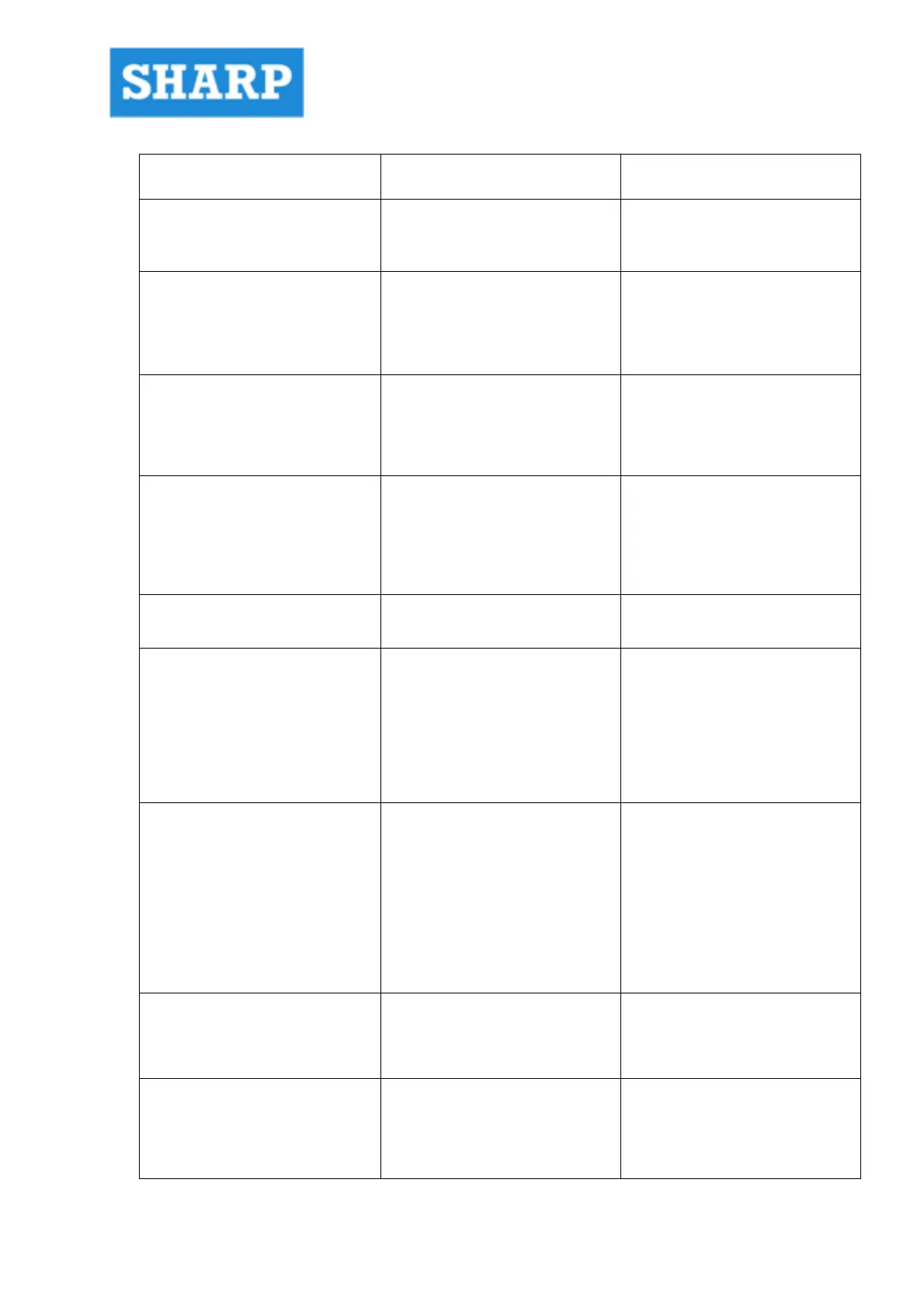

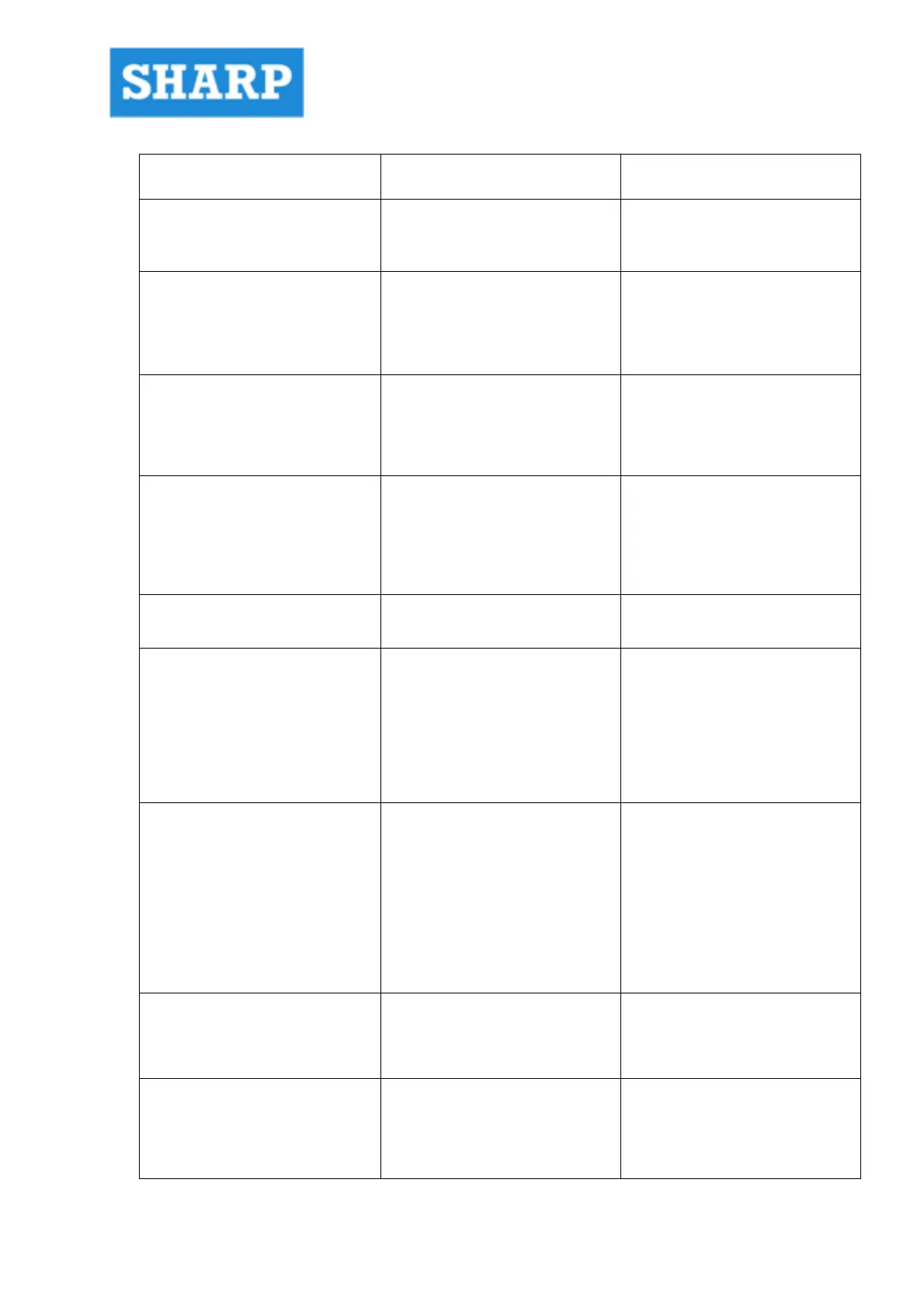

TROUBLE CAUSE CORRECTION

SPINDLE POWER FEED

DISENGAGEMENT NOT

WORK WELL

The two M4 set screw on

disengage lever loosed.

Tighten set screws

HAND MICRO-FEED NOT

WORK

1. Power feed rates selecting

knob set on one of the three

feed.

2. Engage lever not operated.

1. Rotate this knob to one of the

two “DUMMY” positions.

2. Pull engage lever.

V-BELT SLIPS AT CUTTING

1. V-belt tool loose

2. V-belt worm

3. Wrong grooves

1. Tight V-belt

2. Replace V-belt

3. Check grooves

RAPID TRAVERSE OF

FEEDBOX NOT WORK

1. Wrong motor rotating

direction.

2. Multi-disc clutch worm.

3. Rapid traverse shifter worm.

1. Reconnect the power supply

2. Adjust clutch

3. Replace shifter

FEED STOP SUDDENLY

DURING MACHINING

1. Overload makes the shear pin

shear out.

1. Check the overload cause

and replace shear pin

KNEE CAN’T BE POWER

ELEVATED

1. Knee is locked on column.

2. Over weight of workpiece,

fixtures.rtc.(max. Load

capacity: 300kgs)

3. Poor lubricating between

knee and column

1. Release lock bolts

2. Use hand elevating

CANNOT HOLD SIZE

1. Cutting load too great.

2. May be due to chip packing.

3. Chips causing misalignment.

1. Decrease number of teeth in

contact with workpiece

2. Increase oil pressue in

redirect flow so as wash

chips out of teeth.

3. Brush or blow all chips away

before mounting new piece of

work.

PREMATURE CUTTER

DULLING

Cutting load too great 1. Decrease number of teeth in

contact with workpiece.

2. Add blending oil to lubricant

CUTTING “HOGSIN”

1. Peripheral relief too great.

2. Rake, angle too large

3. Improper speed

1. Use recommended angle

2. Decrease rake angle

3. Check and adjust

Loading...

Loading...