MX3500N SIMULATION 7 – 20

9

9-2

Purpose

Operation test/check

Function (Purpose)

Used to check the operations of the sen-

sors and detectors in the duplex section

and its control circuit.

Section

Duplex

Item

Operation

Operation/Procedure

The sensor and detector operation conditions are displayed.

The active sensors and detectors are highlighted.

9-3

Purpose

Operation test/check

Function (Purpose)

Used to check the operations of the loads

in the duplex section and the control cir-

cuits.

Section

Duplex

Item

Operation

Operation/Procedure

1) Select the item to be operation tested with the buttons on the

touch panel.

2) Press [EXECUTE] button.

The selected load operation is performed.

When [EXECUTE] button is pressed, the output is terminated.

10

10-1

Purpose

Operation test/check

Function (Purpose)

Used to check the operations of the toner

motor and the related circuit.

Section

Process (Developing)

Item

Operation

Operation/Procedure

* Before execution of this simulation, remove the toner cartridges.

1) Select the item to be checked with the buttons on the touch

panel.

2) Press [EXECUTE] button.

* The selected load operation is performed for 10 sec.

* When [EXECUTE] button is pressed, the operation is termi-

nated.

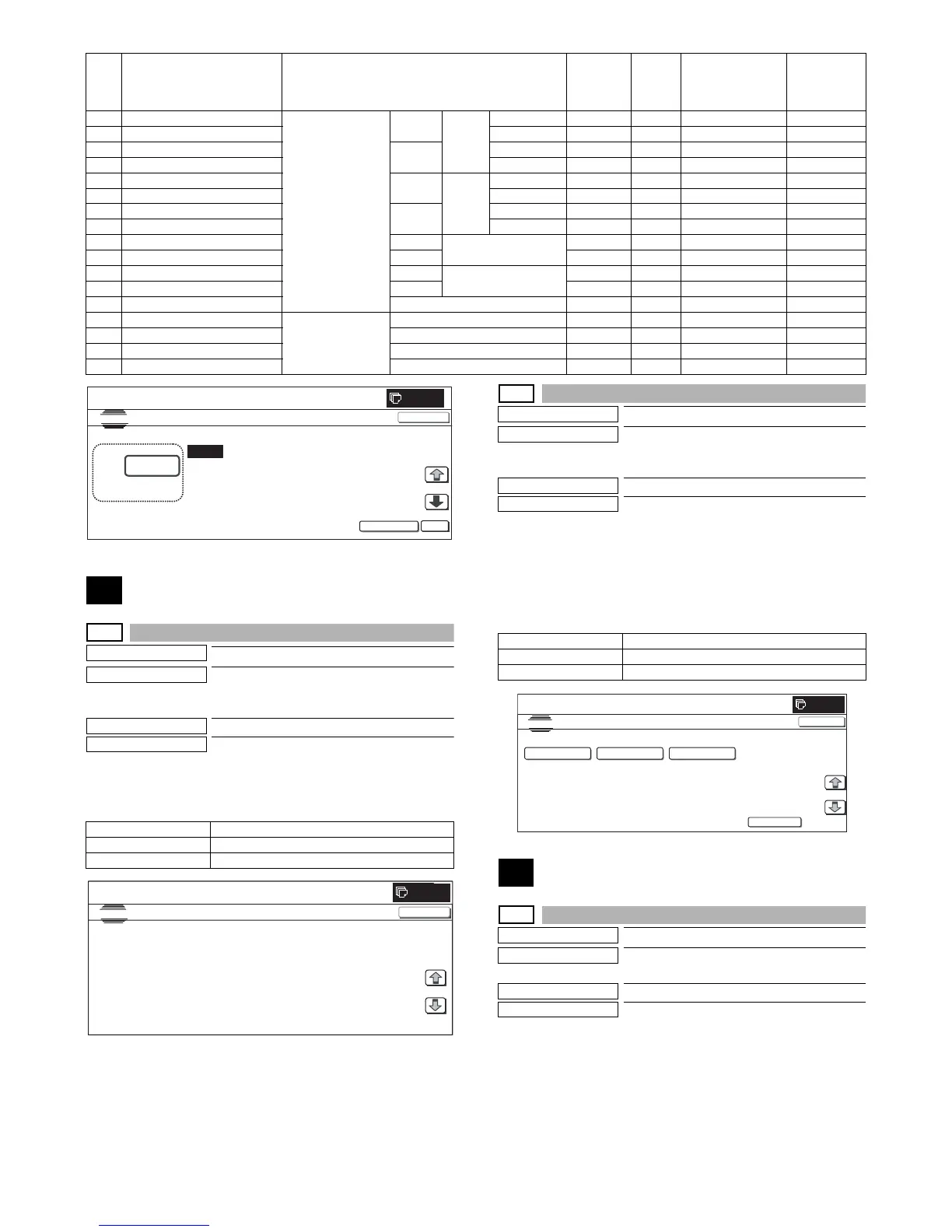

H TC2 PLAIN CL SPX Secondary transfer

bias reference

value

COLOR Normal

paper

Front surface 51 to 255 136 2µA to 45µA20µA

I TC2 PLAIN CL DPX Back surface 51 to 255 136 2µA to 45µA20µA

J TC2 PLAIN BW SPX BLACK Front surface 51 to 255 117 2µA to 45µA16µA

K TC2 PLAIN BW DPX Back surface 51 to 255 117 2µA to 45µA16µA

L TC2 HEAVY CL SPX COLOR Heavy

paper

Front surface 51 to 255 79 2µA to 45µA8µA

M TC2 HEAVY CL DPX Back surface 51 to 255 70 2µA to 45µA6µA

N TC2 HEAVY BW SPX BLACK Front surface 51 to 255 79 2µA to 45µA8µA

O TC2 HEAVY BW DPX Back surface 51 to 255 70 2µA to 45µA6µA

P TC2 OHP CL COLOR OHP 51 to 255 65 5µA to 45µA5µA

Q TC2 OHP BW BLACK 51 to 255 65 5µA to 45µA5µA

R TC2 ENVELOPE CL COLOR Envelope 51 to 255 184 5µA to 45µA30µA

S TC2 ENVELOPE BW BLACK 51 to 255 184 5µA to 45µA30µA

T TC2 CLEANING Cleaning process 51 to 255 79 5µA to 45µA8µA

U TC2 CLEAN LOW SPD Secondary transfer

cleaning bias

reference value

Low speed print 51 to 255 72 –50V to –1500V –200V

V TC2 CLEAN MIDDLE SPD Middle speed print 51 to 255 100 –50V to –1500V –400V

W TC2 CLEAN HIGH SPD High speed print 51 to 255 114 –50V to –1500V –500V

X TC2 CLEAN CLEANING Cleaning 51 to 255 156 –50V to –1500V –800V

Item Display Content

Setting

range

Default

value

Actual output

setting range

Default

value

Actual

output value

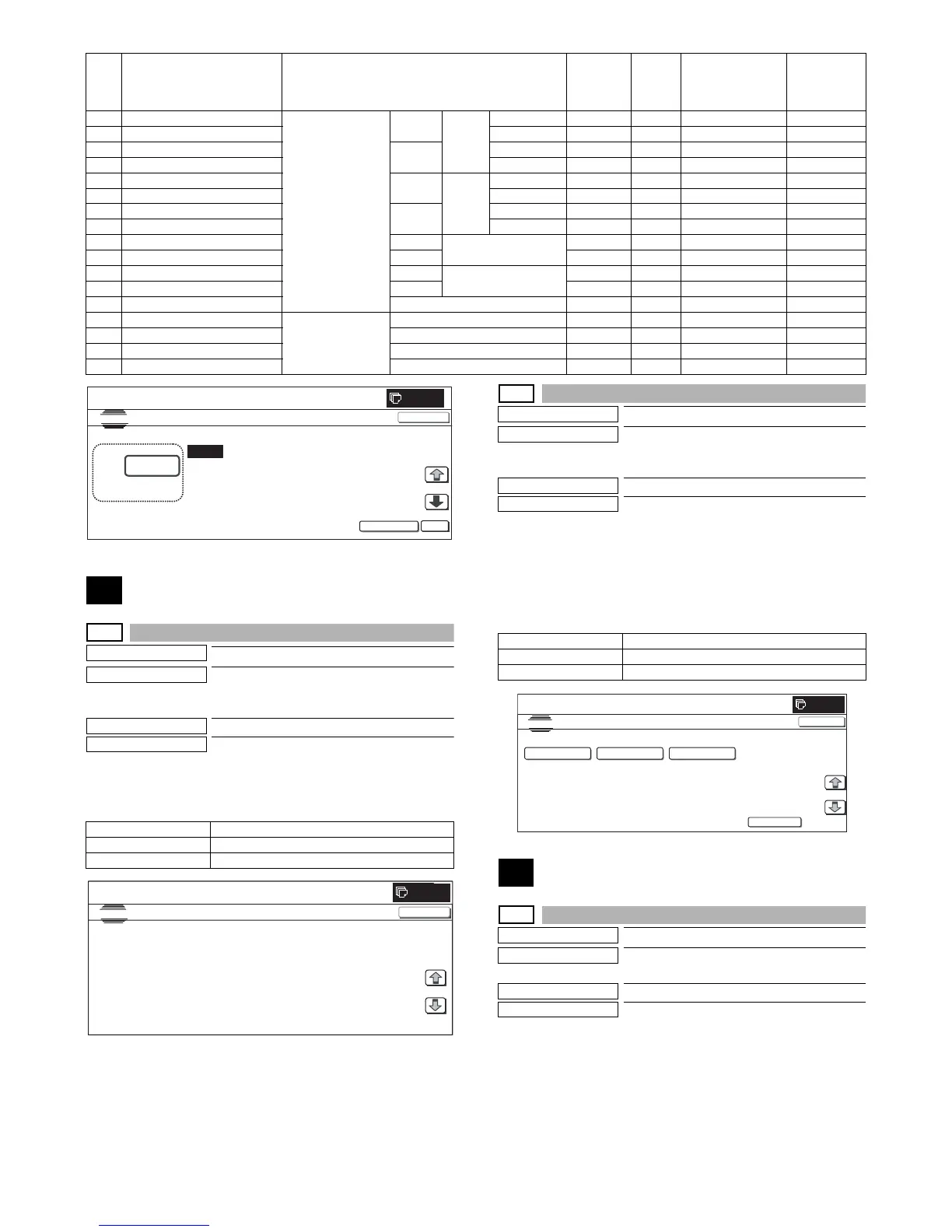

DSW_ADU ADU transport open/close detection

APPD1 ADU transport path detection 1

APPD2 ADU transport path detection 2

CLOSE

A:

A : 232

B : 232

C: 139

TC1 LOW SPEED

CL

K

TC1 MIDDLE SPEED

CL

K

TC1 LOW SPEED

CL

CMY

SIMULATION

NO.08-06

THV S E TTING AND OUTPUT

232

[ 0~255]

OK

TEST

EXECUTE

0

D : 139

TC1 MIDDLE SPEED CL

CMY

CLOSE

0

ADU SENSOR CHECK

1/1

CLOSE

SIMULATION

NO.09

㧙

02

TEST

1/1

DSW_ADU

APPD1 APPD2

ADUM_L ADU motor lower

ADUM_U ADU motor upper

ADUGS ADU gate solenoid

0

SIMULATION

NO.09-03

TEST

ADU LOAD CHECK

EXECUTE

1/1

ADUM_L

ADUM_U

ADUGS

CLOSE

Loading...

Loading...