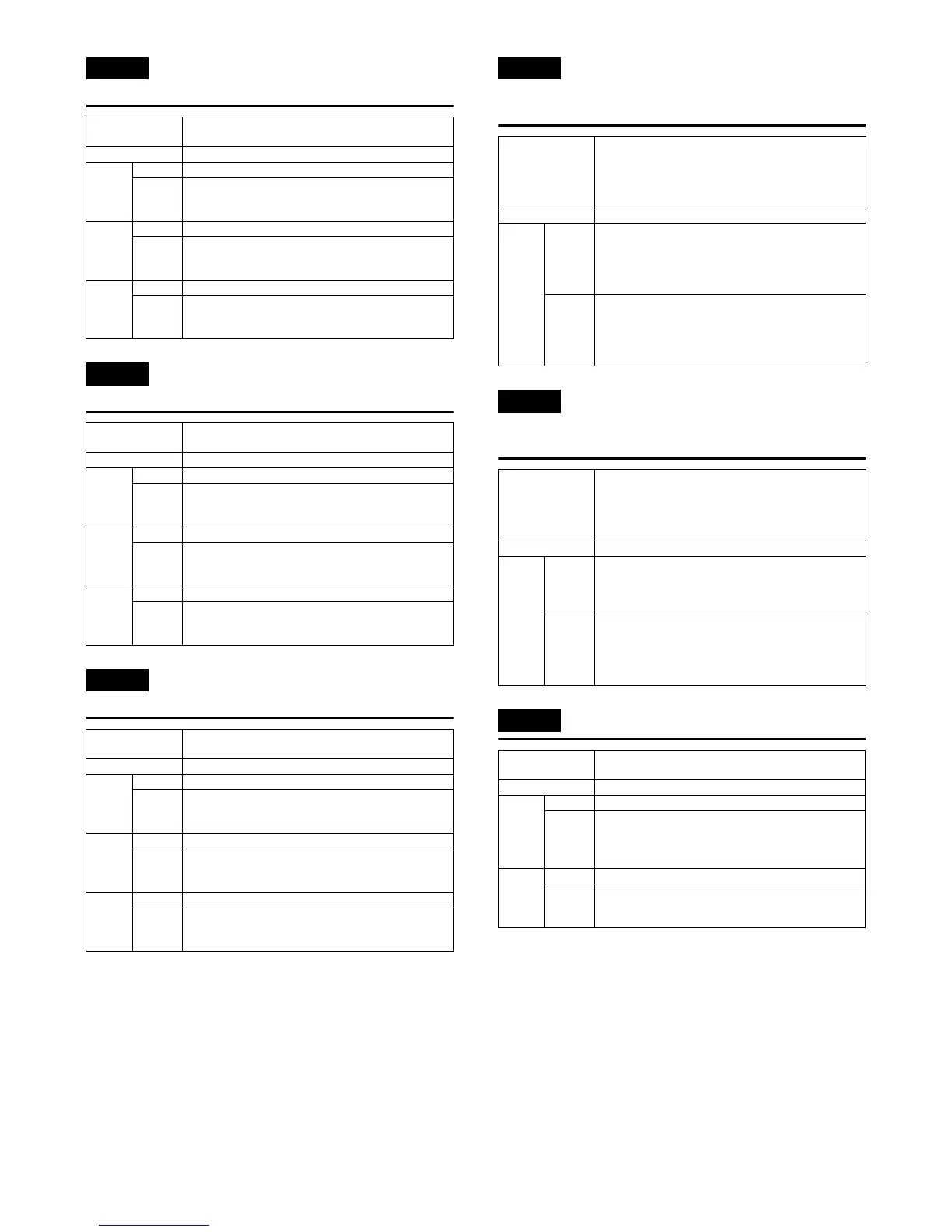

MX3500N SELF DIAG AND TROUBLE CODE 8 – 16

F2-41 Toner empty sensor abnormality

(CYAN)

F2-42 Toner empty sensor abnormality

(MAGENTA)

F2-43 Toner empty sensor abnormality

(YELLOW)

F2-44 Black exclusive image density sensor

trouble (Transfer belt surface

reflection ratio abnormality)

F2-45 Color exclusive image density sensor

trouble (Calibration plate surface

reflection ratio abnormality)

F2-49 LSU thermistor trouble

Trouble content Toner empty sensor output abnormality. Sample level

25 or less or 231 or above.

Section PCU

Case 1 Cause The connector is not installed.

Check

and

remedy

Check the connection of the connector harness to the

PCU PWB. Check the connection of the toner empty

sensor.

Case 2 Cause Connector harness trouble

Check

and

remedy

Check the harness disconnection.

Case 3 Cause Cartridge trouble

Check

and

remedy

Check the cartridge connection.

Trouble content Toner empty sensor output abnormality. Sample level

25 or less or 231 or above.

Section PCU

Case 1 Cause The connector is not installed.

Check

and

remedy

Check the connection of the connector harness to the

PCU PWB. Check the connection of the toner empty

sensor.

Case 2 Cause Connector harness trouble

Check

and

remedy

Check the harness disconnection.

Case 3 Cause Cartridge trouble

Check

and

remedy

Check the cartridge connection.

Trouble content Toner empty sensor output abnormality. Sample level

25 or less or 231 or above.

Section PCU

Case 1 Cause The connector is not installed.

Check

and

remedy

Check the connection of the connector harness to the

PCU PWB. Check the connection of the toner empty

sensor.

Case 2 Cause Connector harness trouble

Check

and

remedy

Check the harness disconnection.

Case 3 Cause Cartridge trouble

Check

and

remedy

Check the cartridge connection.

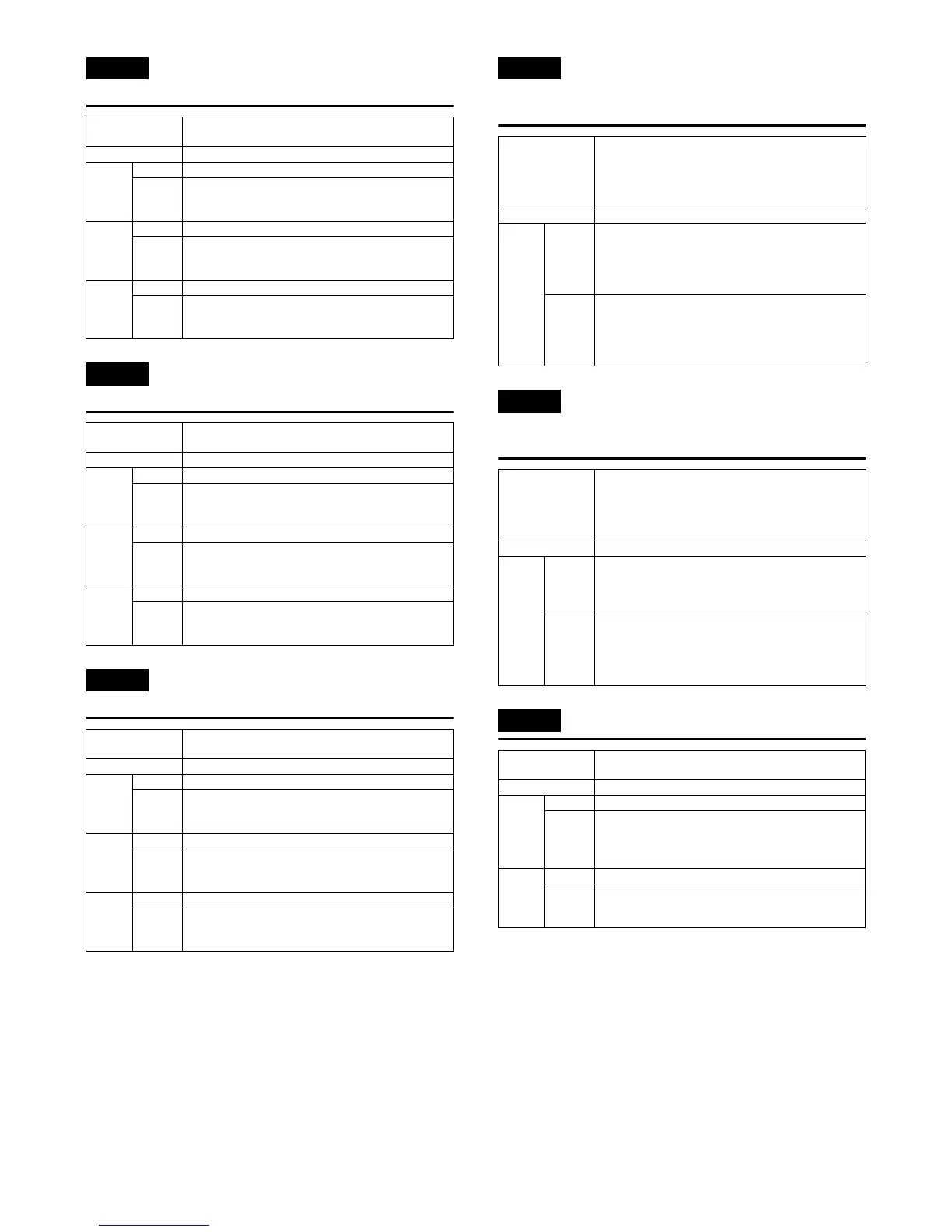

Trouble content The transfer belt surface is scanned by the image

density sensor before starting the process control, and

adjust the sensor gain so that the output is kept at a

certain level. However, the output is not within the

specified range though the senor gain is adjusted.

Section PCU

Case 1 Cause Image density sensor trouble, harness connection

trouble between PCU PWB and the image density

sensor, image density sensor dirt, transfer belt

cleaning trouble, calibration plate solenoid operation

trouble

Check

and

remedy

Use SIM44-2 to execute the process control sensor

gain adjustment. If "ERROR" is displayed, check the

sensor, the harness, the calibration plate solenoid

operation for any trouble. If the adjustment is

completed, check the transfer belt surface state.

Trouble content The calibration plate surface is scanned by the image

density sensor before starting the process control, and

adjust the sensor gain so that the output is kept at a

certain level. However, the output is not within the

certain level though the senor gain is adjusted.

Section PCU

Case 1 Cause Image density sensor trouble, harness connection

trouble between PCU PWB and the image density

sensor, image density sensor dirt, calibration plate

dirt, calibration plate solenoid operation trouble

Check

and

remedy

Use SIM44-2 to execute the process control gain

adjustment. If "ERROR" is displayed, check the

sensor and the harness. If the adjustment is

completed, check the calibration plate solenoid

operation.

Trouble content The detection temperature is out of the range of 5°C

to 55°C.

Section PCU

Case 1 Cause LSU thermistor harness connection trouble

Check

and

remedy

Check the connection of the LSU thermistor harness

and connector.

If the trouble cannot be removed, replace the LSU

thermistor or the PCU PWB.

Case 2 Cause LSU thermistor trouble, PCU PWB trouble

Check

and

remedy

Check the PCU PWB.

If the trouble cannot be removed, replace the LSU

thermistor or the PCU PWB.

Loading...

Loading...