29

PRECISION MACHINE TOOLS Ver 2 Maintenance Manual

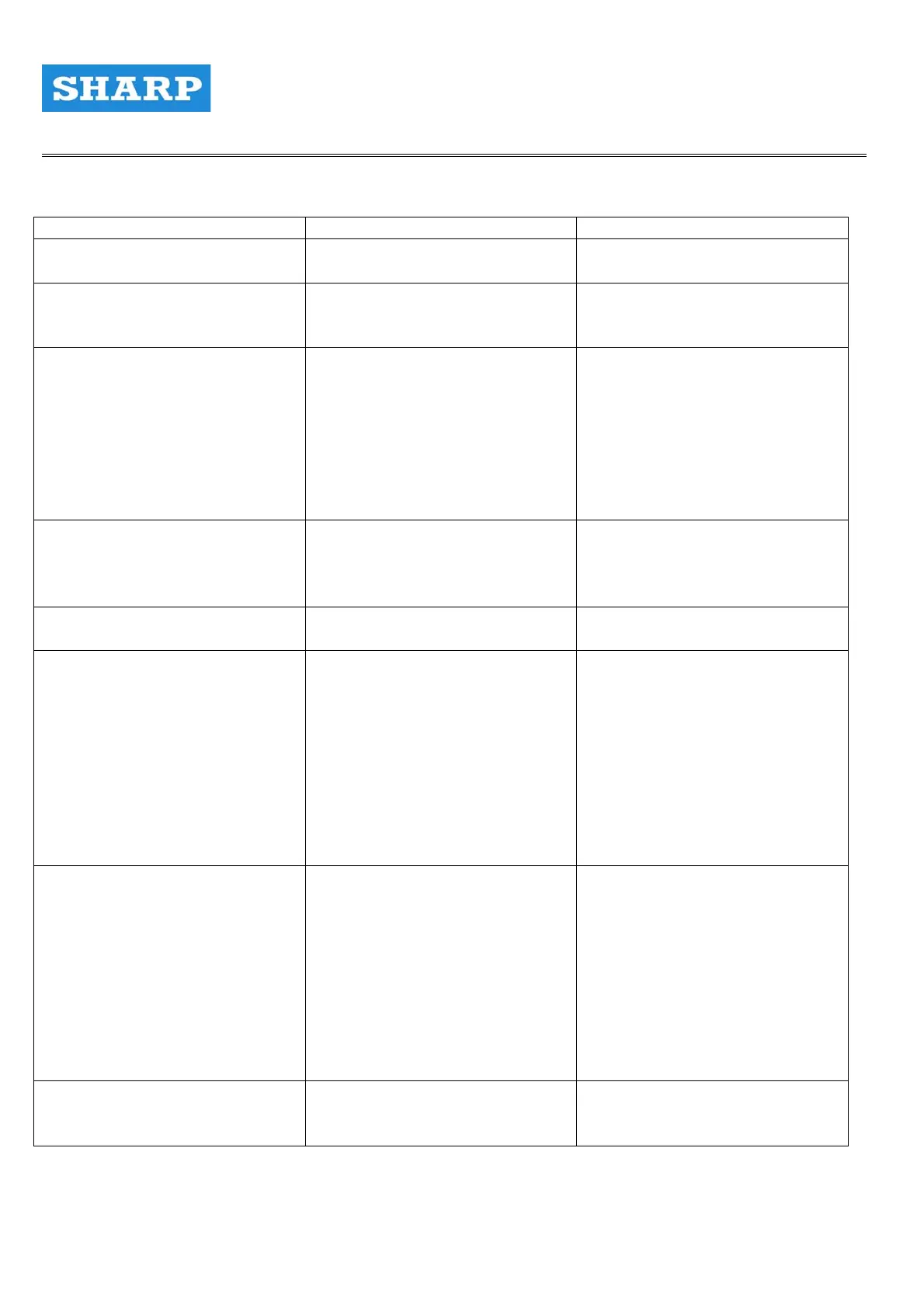

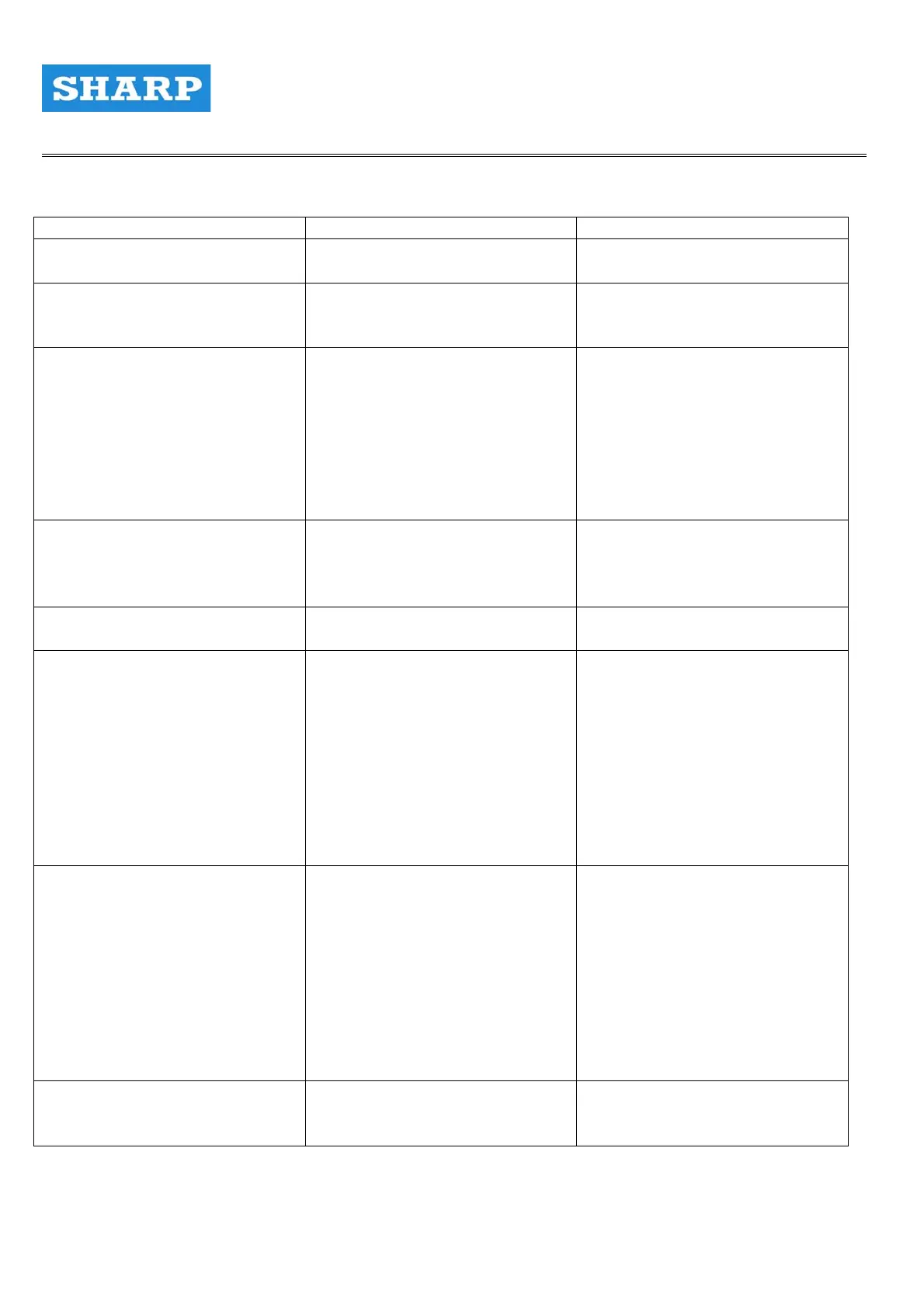

3-6 Air Compressor Unit Troubleshooting

Problem Cause Correction

Reduced pressure source

output

Blocked filter Clean the filter

Gas leakage

1. Loosened nut

2. Broken O-ring

3. Broken tube

1. Tighten the nut

2. Replace the o-ring

3. Replace the tube

Disfunctional pressure

regulator

Broken pressure regulator

1. Broken spring of the

pressure regulator

2. Broken spring of the valve

3. Dust or dirts on the base of

the valve

4. Broken lining of the valve

5. Broken film

1. Replace the spring

2. Replace the spring

3. Clean the valve and the

base

4. Replace the valve

5. Replace the film

Output side air pressure low

1. Dust on the valve base

2. Broken inner lining rubber

3. Broken valve spring

1. Clean the valve and the

valve base

2. Replace the valve

3. Replace the spring

Gas leakage at the screw cap

1. Loosened cap nut

2. Broken film

1. Tighten the cap nut

2. Replace the film

No oil dripped from the oil cup

1. The adjusting needle being

too tight

2. The adjusting needle

cannot be closed or there

are dirts on the needle. The

adjustment needle cannot

bear the pressure

3. Broken or damaged

adjusting needle or needle

base

1. Loosen up the needle

2. Reduce the oil volume until

the level reaches the

maximum oil level

3. Add more oil until the level

reaches between the

maximum and the

minimum level

4. Clean up the blockage

The oil volume cannot be

adjusted

1. The adjustment needle is

too loose

2. The adjustment needle

cannot be closed or dirt on

the needle. The adjusting

needle cannot bear the

pressure

3. Broken or damaged

adjustment needle or

needle base

1. Tighteen the needle and

gradually loosen it for

adjustment

2. Remove the dirt

3. Partial replacement

Oil leadkage at the adjustment

needle

1. The needle is too loose

2. Broken O-ring

1. Tighten up the adjustment

needle

2. Replace the O-ring

Loading...

Loading...