4

PRECISION MACHINE TOOLS Ver 2 Maintenance Manual

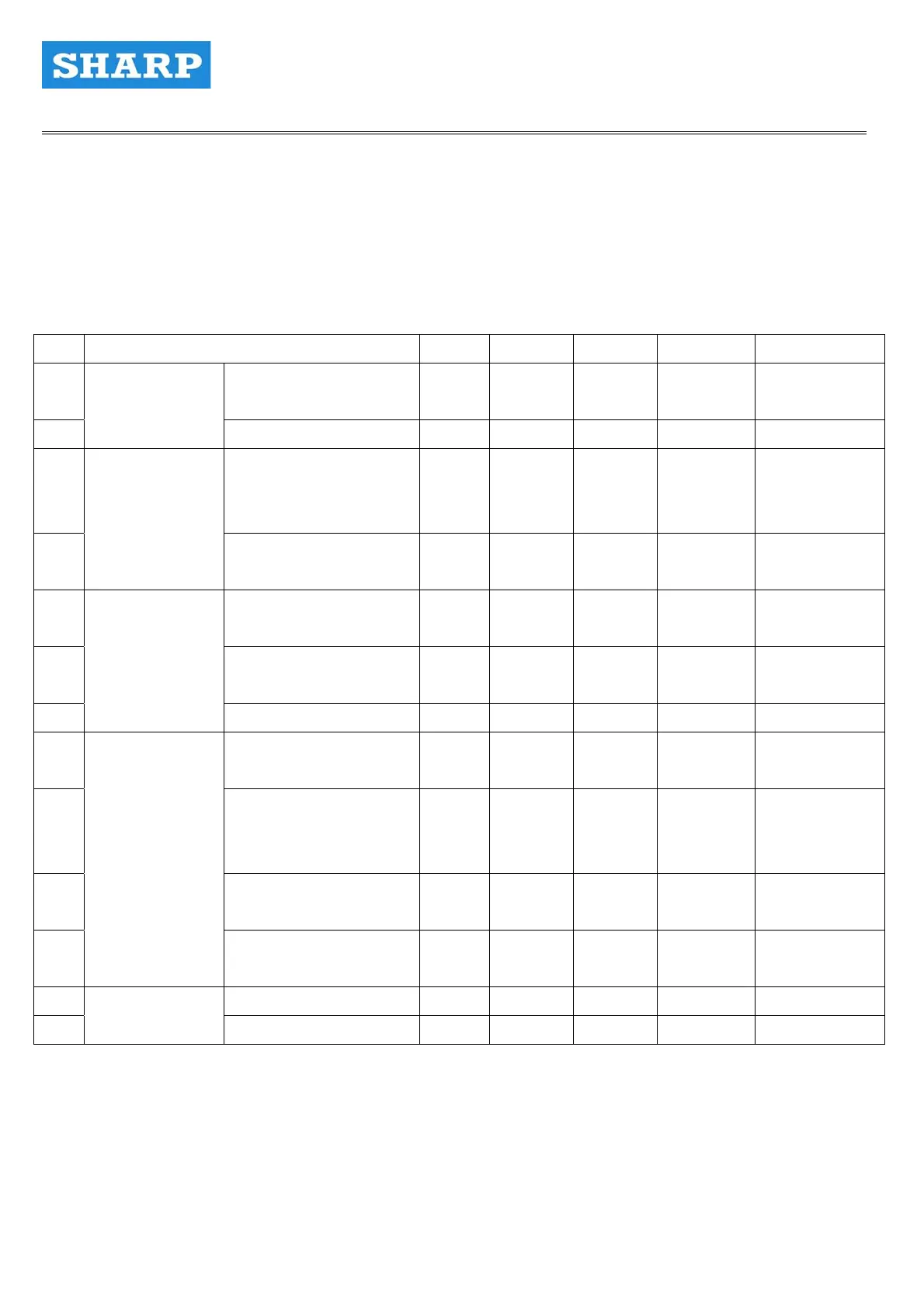

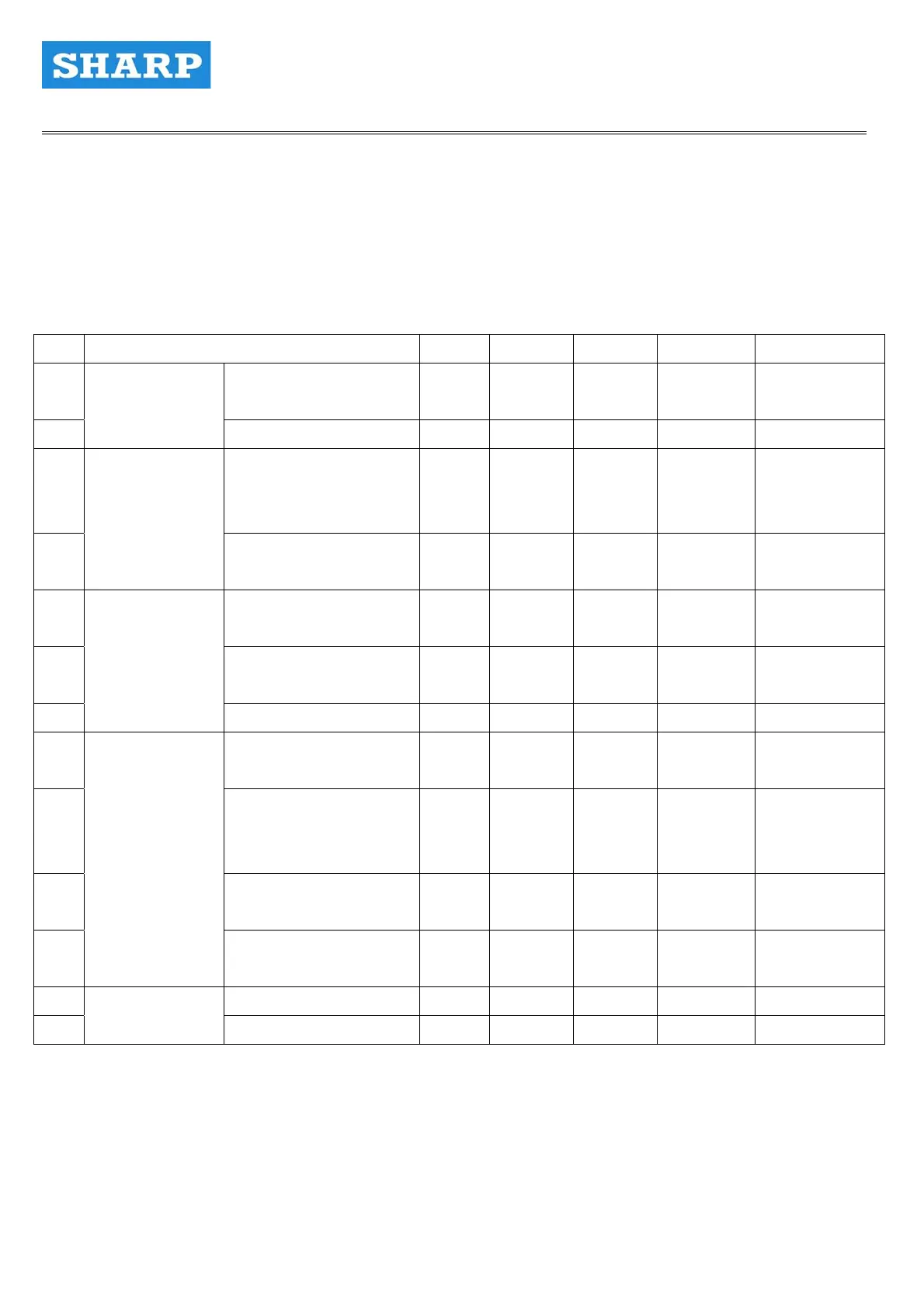

1-1 Routine Maintenance Checklist

Routine maintenance inspection can be classified into daily, weekly, monthly and annually. The

maintenance is given when the machine functions normally The actual frequency and the operation

frequency are different. When operating the both, pay attention to abnormal noises, oil volume, air

pressure and machine abnormalities during the processing.

○:Check ◎:Add oil ☉:Clean

A:Adjustment F: Function check G: Grease coasting R: Replace when necessary

No. Maintenance Daily Weekly Monthly Annually Note

1

Spindle operation

warm-up

○

2

Spindle unit

Spindle nose

☉

3

Lubrication pump

☉

Depending

on the brand

of the lube oil

4

Lubrication

unit

Lubrication pump

oil volume

◎

5

Spindle oil

coolant unit

○

☉

6

Temperature

difference setup

○ -1°C

7

Spindle oil

coolant unit

Oil coolant unit filter

☉

8

Air compressor

source pressure

○ 5.5~7 kgf/cm²

9

Air compressor

cylinder and filter

drainage

○

10

Air compressor

unit lube oil

◎

11

Air

Compressor

Unit

Air leakage of the air

compressor system

○

12 Coolant capacity ○

13

Coolant

Coolant box filter

☉

Loading...

Loading...