49

PRECISION MACHINE TOOLS Ver 2 Maintenance Manual

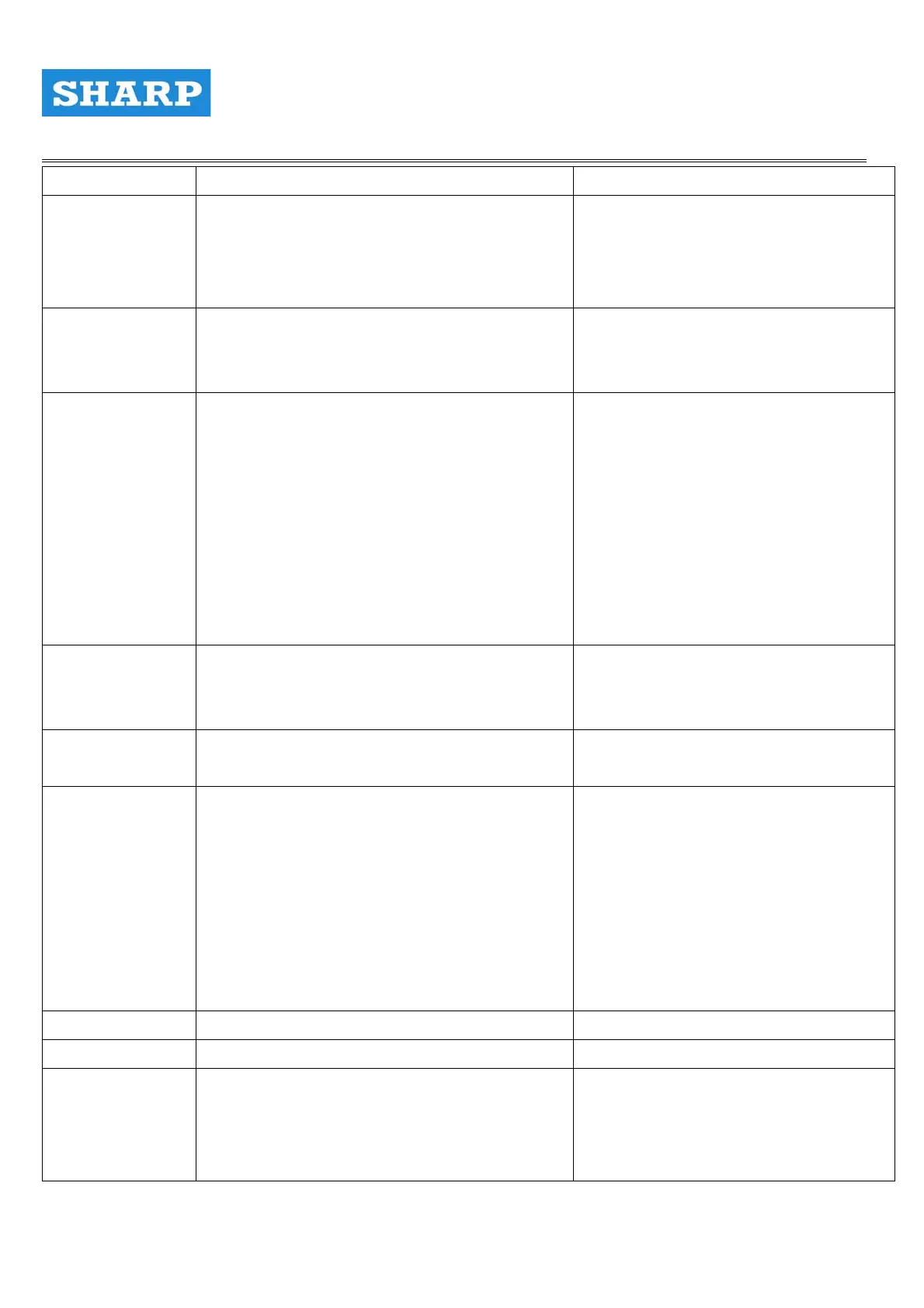

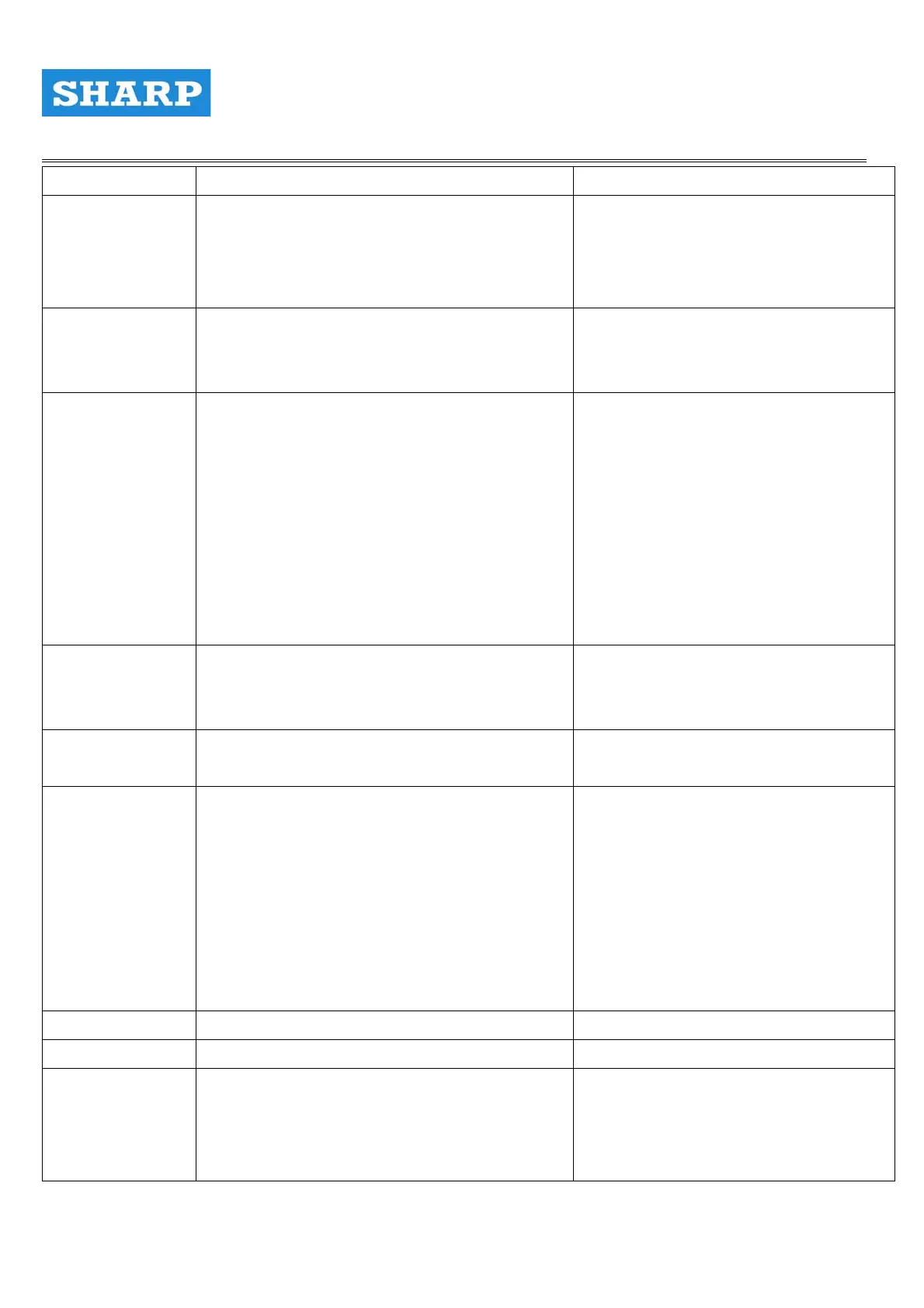

Condition Cause Remedy

Power lamp

is off

1. LED burnt

2. PC board fuse blown

3. Transformer burnt

4. Wire 18,19 loose connection

1. Replace PC board

2. Replace fuse

3. Replace transformer

4. Reconnect wire 18,19

REV is lighted

1. 3 phase power reverse value 3 phase

is above ±10%

2. Pressure reduction and differential

1. Switch any 2 of the R.S.T wires

2. Stability power source

OPS is lighted

1. Inlet oil pipe is clogged or loosened

2. Inlet & outlet are reversed

3. Pump motor runs reverse

4. Pump can not run

5. Circulation oil is not enough

6. Oil filter is dirty

7. Oil pressure switch breakdown

1. Check, clean and lock pipe

2. Correct position of in/outlet

3. Check over-relay of 51p red

and white lines.

4. Replace oil pump

5. Supply circulation oil

6. Replace new filter

7. Adjust oil pressure switch DIFF,

0.3 kgf/cm² range 0.8~0.8 cmHg

PUMP is lighted

1. Overload relay is off

2. Pump switch is off

3. Inlet pipe is clogged

1. Reset switch

2. Reset pump switch

Clean pipe and replace oil filter

COM is lighted

1. Overload relay off

2. Compressor breakdown

1. Reset switch

2. Replace compressor

HP is lighted

1. Condenser is too dirty

2. Air filter is not clean

3. Cooling fan doesn’t run or blades fall.

4. Cooling medium pressure switch

breakdown.

5. Cooling medium is leaking

1. Use compress air to clean fins

and restart cooler.

2. Clean filter.

3. Lock fan blades tightly or replace

fan motor.

4. Replace cooling medium

pressure switch.

5. Irrigate cooling medium.

RA is lighted 1. Room temp. sensor breakdown 1. Replace RA sensor

RO is lighted 1. Oil temp. sensor breakdown 1. Replace RO sensor

OT is lighted

1. Oil temp. is to high

2. Temp. sensor blown

3. Check cooling medium is enough or not.

1. Stop running cooler until oil temp.

returns to normal range start again

2. Replace temp sensor.

3. Supply cooling.

Loading...

Loading...