As an alternative, you can connect the grounding conductor without cable lugs using a terminal

plate at the marked connection point.

Connecting the grounding conductor

● Ensure that the connecting surface is bare and is protected against corrosion using a

suitable substance, e.g. acid-free vaseline.

● Arrange the flat washer and spring washer under the bolt head.

● Check that the maximum permissible clamping thickness of 10 mm for the cable lug or strap

is not exceeded.

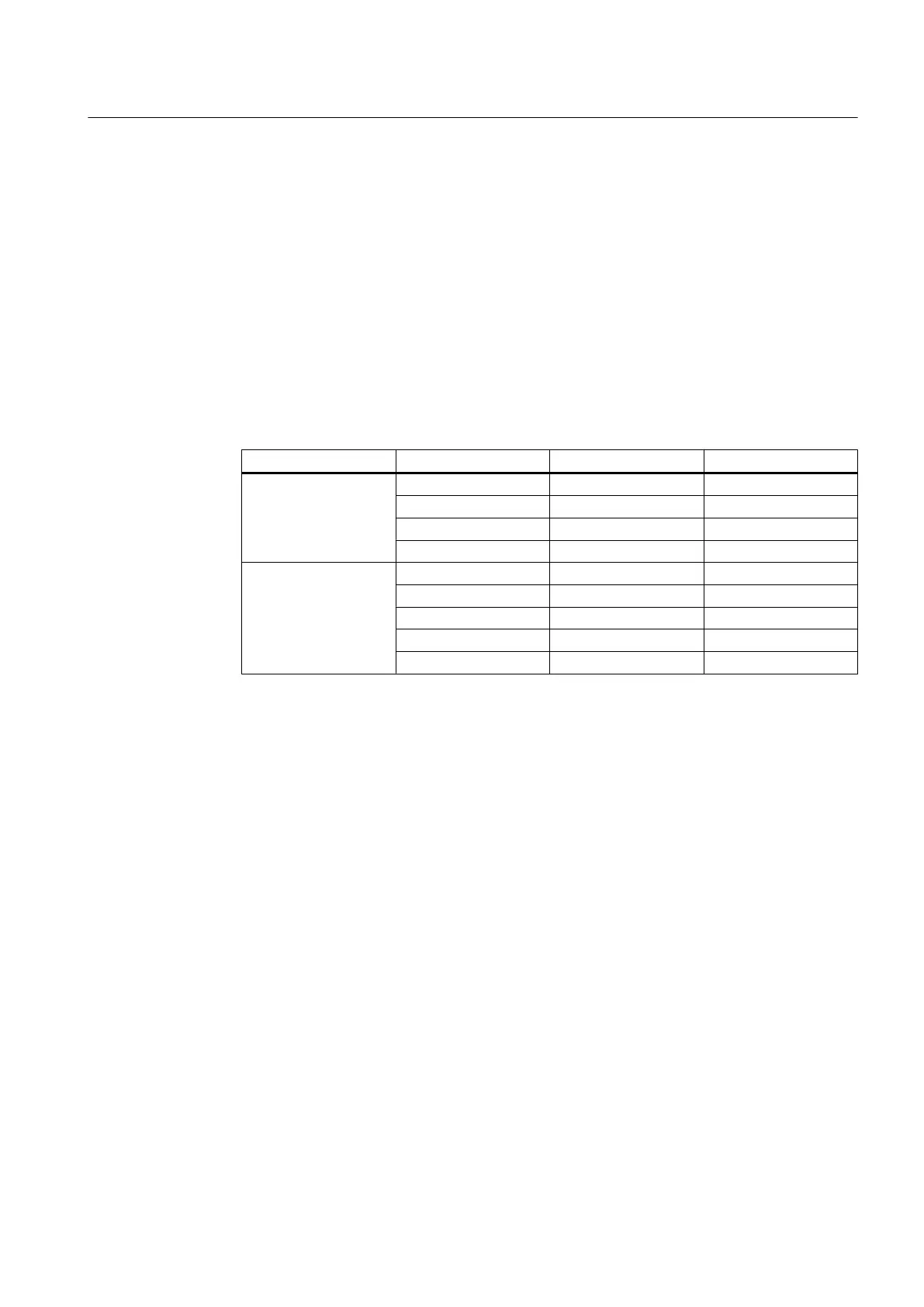

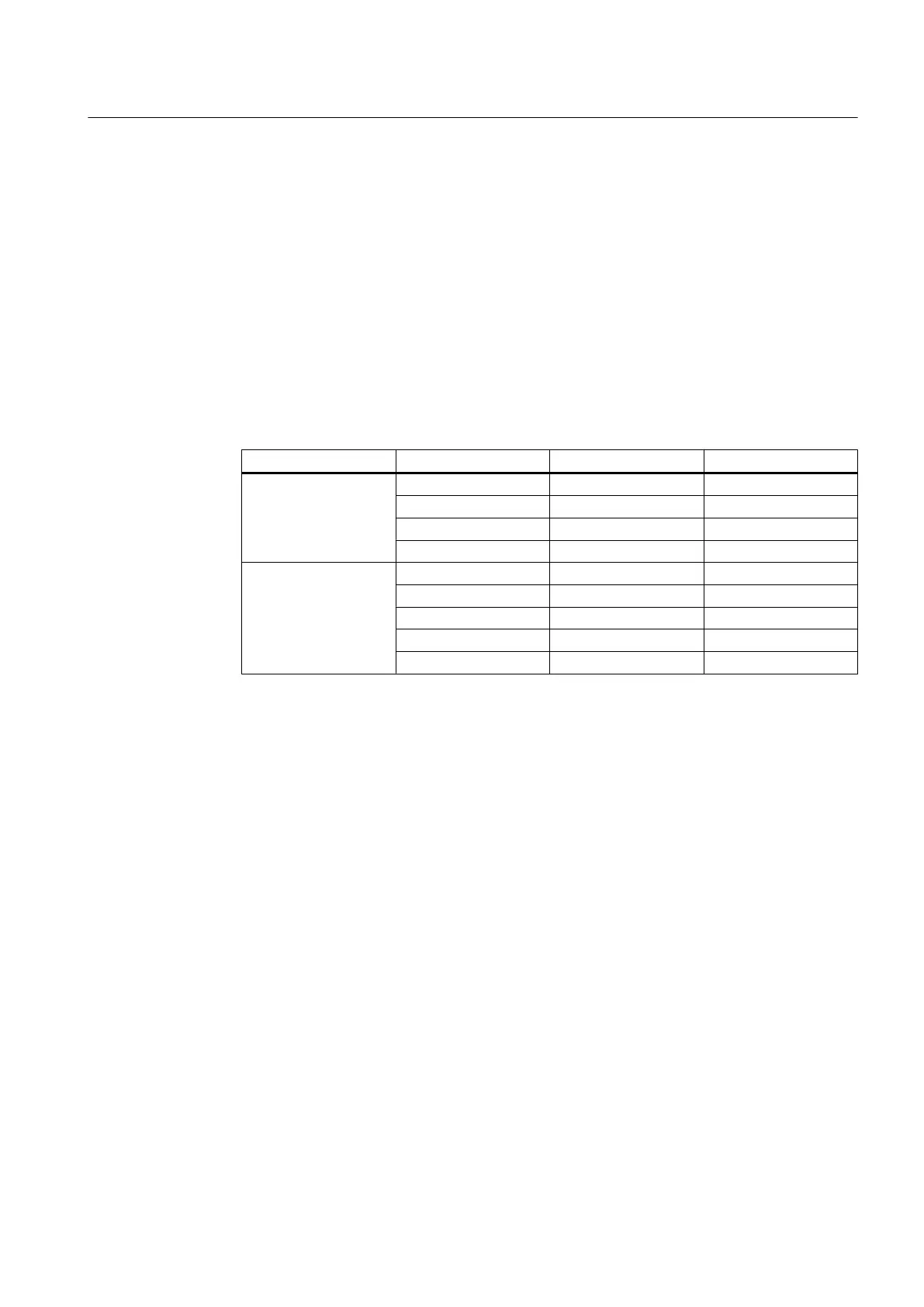

● Fasten the clamping screw according to the following table. Screw-in depth and tightening

torque are different depending on whether cable lugs or ground terminals are used.

Screw Screw-in depth Tightening torque

When using cable lugs M6 > 6 mm 8 Nm

M8 > 8 mm 20 Nm

M12 x 25 > 16 mm 38 Nm

M16 x 35 > 20 mm 92 Nm

When using grounding

terminals

M6 > 9 mm 8 Nm

M8 > 12 mm 20 Nm

M10 > 15 mm 40 Nm

M12 > 18 mm 70 Nm

M16 > 20 mm 170 Nm

● Use the connecting terminals designated for the grounding conductor in the terminal box.

See also

Converter operation (Page 77)

6.3.5 Radio-frequency grounding for converter operation

In converter operation, the converter emits RF alternating currents. To establish and RF-

specific optimal connection between motor terminal box and motor enclosure, you can use

flexible braided copper flat cables with low impedance and a broad frequency range.

Establish the radio-frequency ground connection with flat cables. Alternatively you can

establish the radio-frequency ground connection with cable lugs.

Electrical connection

6.3 Preparation

SIMOTICS TN Series N-compact 1LA8

Operating Instructions 05/2016 65

Loading...

Loading...