Information for using the motors

7.8 Vibration stressing

1PH7 induction motors (Machine tools)

Configuration Manual, (APH7W), 04/2009, 6SN1197-0AD72-0BP0

231

7.8 7.8 Vibration stressing

External vibrations are introduced into the motor through the motor foundation and/or the

drive mechanical transmission through the motor frame and/or through the rotor. In order to

ensure perfect functioning of the drive as well as a long motor lifetime, these types of

vibrations, introduced into the drive system, should not exceed the specific limit values of the

motor.

Vibration caused by the rotor must be minimized by appropriately balancing the motor.

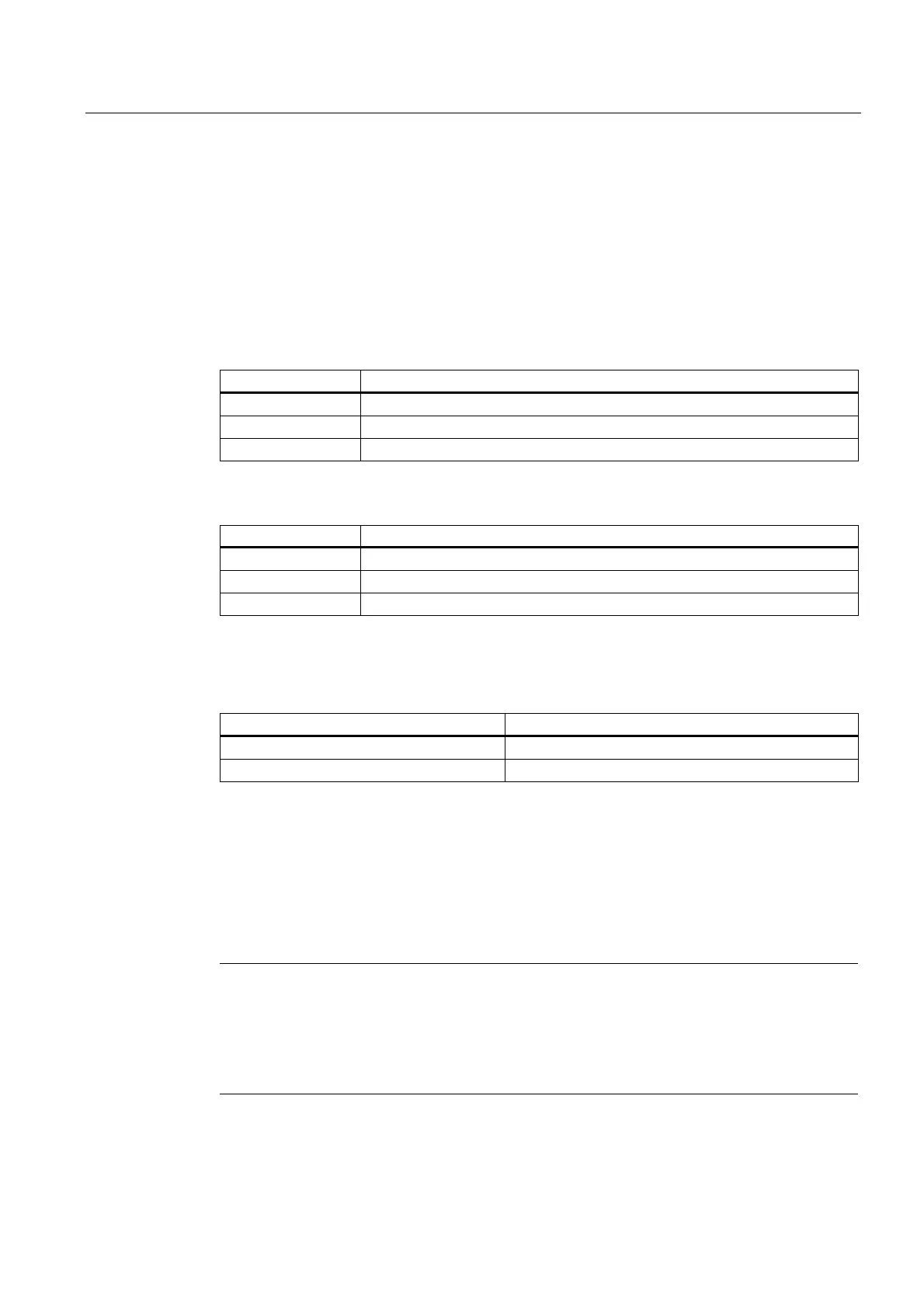

Table 7- 5 Vibration values for SH 100 to 160

1)

Vibration frequency Vibration values

< 6.3 Hz Vibration displacement s ≤ 0.16 mm

6.3 ... 250 Hz Vibration velocity v

rms

≤ 4.5 mm/s

> 250 Hz Vibration acceleration a ≤ 2.55 m/s

2

Table 7- 6 Vibration values for SH 180 to 225

1)

Vibration frequency Vibration values

< 6.3 Hz Vibration displacement s ≤ 0.25 mm

6.3 ... 63 Hz Vibration velocity v

rms

≤ 5.0 mm/s

> 63 Hz Vibration acceleration a ≤ 4.0 m/s

2

To ensure problem-free operation and a long service life, the vibration values specified to

ISO 10816 must not be exceeded at the defined measuring points on the motor.

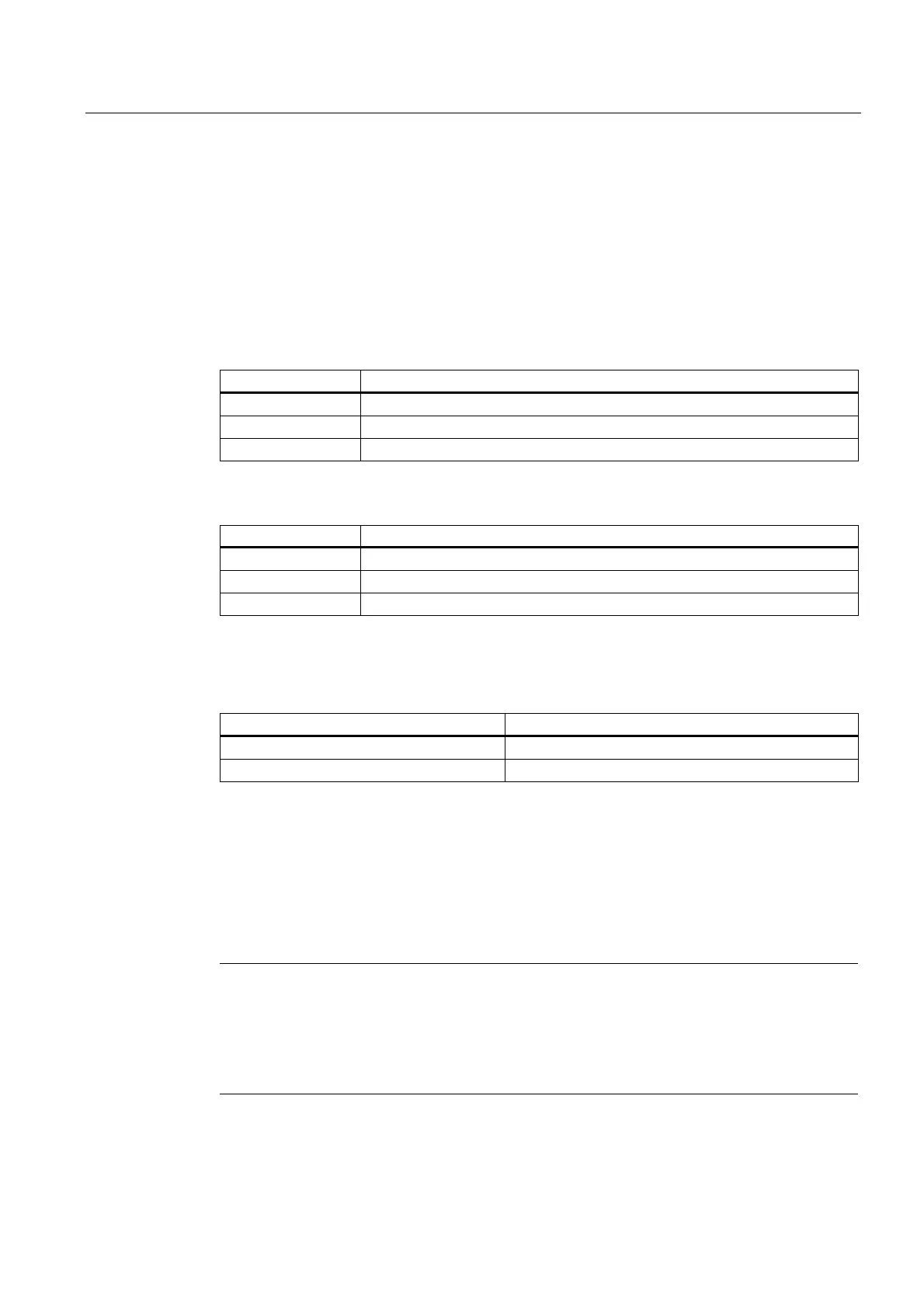

Table 7- 7 Max. permissible radial and axial vibration values

1)

Vibration velocity V

rms

[mm/s] Vibration acceleration a

peak

[m/s

2

]

4.5 10 radial

4.5 2.25 axial

1) Both values must be observed simultaneously

To measure the vibration velocity, the measuring equipment must fulfill the requirements of

ISO 2954. The vibration acceleration must be measured as a peak value in the time range in

a frequency band of 10 to 2000 Hz.

If appreciable vibration excitation in excess of 2000 Hz (e.g. gear teeth meshing frequencies)

can be expected, the measurement range must be adapted accordingly. This does not alter

the maximum permissible values.

Note

Uninterrupted duty within the natural frequencies

Uninterrupted duty in the natural frequencies of the installed/mounted system must be

avoided, as this generally leads to the permissible vibration values being exceeded and the

system being damaged. To reduce vibration, the flanged-mounted motors can be supported

at the NDE.

Loading...

Loading...