www.silverlinetools.com

47

Restraint Kit 254301

• The karabiner must be able to move freely and without interference

during use. ANY constraint or external pressure is DANGEROUS

• Be aware that some equipment combinations may reduce the effective

strength of the karabiner (e.g. when connecting to wide straps)

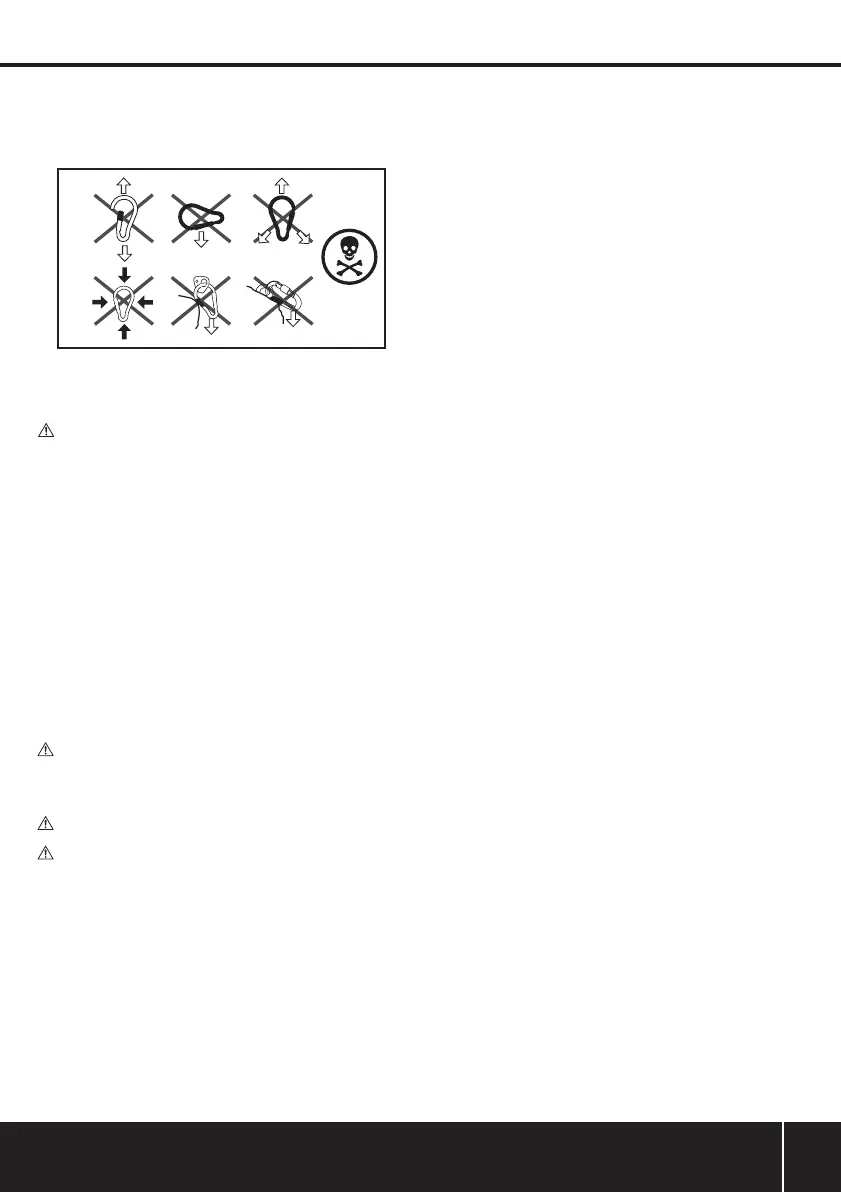

Fig. G

Note: Regularly check connections with other equipment in the system

during use, and ensure various system components are correctly

positioned with respect to each other. This may save your life!

Rescue plan

WARNING: A suitable and sufficient risk assessment must be carried

out before commencing with any kind of work at height, or any work

that requires the use of personal protective equipment (PPE) as a control

measure.

• The user must have a rescue plan and the means at hand to

implement it

• The plan must take into account the equipment and special training

necessary to effectively conduct prompt rescue under all foreseeable

conditions

Accessories

• Additional fall arrest gear, workwear and other personal protection

equipment is available from your Silverline stockist

Maintenance

Note: All fall arrest equipment must be regularly inspected, cleaned and

maintained by a competent person, in accordance with local laws and

regulations. Maintenance must be recorded in a dedicated service record

(see end of this manual).

WARNING: Carry out a visual and tactile inspection of all components

every time the equipment is used. Carry out a detailed examination if the

equipment has not been used for some time. Note: A thorough, detailed

examination of the equipment must be carried out at regular intervals, at

least once annually, or more frequently depending on use.

WARNING: It is ILLEGAL to carry out any kind of repair or modification to

this equipment.

WARNING: Should any damage be detected, remove the equipment from

service immediately. It must then be rendered unusable and discarded.

Inspection procedures

• The following procedure helps detect defects potentially resulting

in degradation and/or weakening of the Karabiner (2) and Scaffold

Hook (1) :

1. Inspect for missing or altered parts. Refer to the image in ‘Product

Familiarisation’ for identification. Verify each item is present and has

not been tampered with

2. Inspect the entire karabiner or hook for cracks, nicks or breaks in

the metal. Inspect every millimetre

Note: If necessary, clean before inspection, so that even small hairline

cracks are visible.

3. Inspect for deformation, bent or dented parts. Open the gate and

inspect the nose of the karabiner or hook for signs of wear, distortion

or damage

4. Inspect the metal surface for any signs of corrosion. Steel karabiners

and hooks may show red dust as evidence of corrosion; aluminium

karabiners may develop pitting or scales

5. Inspect for heat damage, which can usually be seen as

discolouration or darkening of the metal surfaces

6. Perform a functional test: The locking mechanism must function

easily, and the karabiner or hook must fully open and close smoothly

and easily. When locked, the gate MUST NOT open under pressure

from any direction

• Slowly pass the rope through your hands to detect small defects,

abrasions and twist damage. Feel for softening and hardening of fibres

and look for ingress of contaminants

• The following defects potentially result in degradation and/or

weakening of the lanyard:

• Cut/broken fibres or nicks

• Kinks, knots (other than those intended by the manufacturer) or

hockling (unravelling due to constant turning of the rope in the same

direction, or due to shock loading)

• Brittle, fuzzy or worn fibres, fraying or abrasions

• Overall deterioration or discolouration

• Any kind of modification/attempted repairs

• Hard or shiny spots, fused fibres or strands

• Heat or friction damage indicated by fibres with a glazed

appearance which may feel harder than surrounding fibres

• Burnt, charred or melted fibres or strands

• Change in diameter, compared to the original diameter (see

‘Specification’)

• Rope marked with paint or a permanent marker

• Loose, missing, deformed or damaged Rope Thimbles (3)

• Eye damage (cuts, nicks, fraying, fusing, abrasion etc.)

• Damage to protective covers/sleeves/sheaths

• Splices starting to unravel, or showing signs of damage or

deterioration

• Partially deployed energy absorber (e.g. short pull-out of tear

webbing)

• Damage to stitching

• Chemical attack potentially resulting in local weakening and

softening (often indicated by flaking of the surface)

• UV light degradation which can be difficult to identify, particularly

visually, but there may be some loss of colour (if dyed) and a

powdery surface

• Contamination (e.g. with dirt, grit, sand etc.) which may result in

internal or external abrasion

• Damaged, oxidised or deformed fittings (e.g. karabiners, screw link

connectors, scaffold hooks)

• Inspect all other components or subsystem of the fall arrest equipment

according to manufacturer's instructions

• Record inspection date and results in a dedicated service record (see

end of this manual)

Note: Refer to ‘Service life and product obsolescence’ if any damage or

other defects are detected during inspection

Cleaning

Note: Correct cleaning is essential to ensure integrity of this equipment.

Follow the cleaning instructions below without deviation.

• Clean the karabiner and hook by wiping it with a soft, lightly oiled cloth

• If this is not sufficient, use warm water with a mild pH neutral (pH 7)

detergent, to clean off any foreign matter. Dry thoroughly and lubricate

moving parts with a suitable spray lubricant

• Clean lanyard in warm water (30 – 60°C) with a mild pH neutral (pH7)

household detergent. In case of minor soiling, wipe with a cotton cloth

or carefully clean using a soft brush

• DO NOT under any circumstances use any abrasive materials, acids,

basic detergents or solvents

254301_Manual.indd 47 28/06/2017 09:08

Loading...

Loading...