Hook

Basic Parts and Locations (continued):

Return to Table of Contents

Basic Parts Descriptions:

•

Top Lid – Holds the thread, and house’s the top tension unit. For the 750, 758 types’, has indicator plate showing settings for

cams, and different patterns available.

• Face Plate – Side cover plate, or door.

• Top Tension Unit – Regulates the stitch appearance. If the knots are on the bottom of the fabric, increase the thread tension

number. If the knots are on the top of the fabric, decrease the thread tension number. It’s a good idea to change the number

setting by one, and test the results.

• Control Panel – Generally has indicator lines showing dial alignments, and covers inside workings of the machine. Also used

to identify the model of your machine.

• Control Panel Emblem – Hides the Control Panel fastening screw. The part is just pressed on, and can be easily removed by

inserting a very small screwdriver behind the lower portion of the Emblem, and gently lifting outwards.

• Presser Foot – Holds the fabric down while sewing. Presser feet vary, depending on their intended usage.

• Needle Plate – Generally has seam guidelines, and like the presser foot, it comes in different designs for different purposes.

• Slide Plate – Covers the Bobbin Case area, and is held down with a flat spring. Don’t ever lift this unit up to high, as you’ll

bend or brake the flat spring.

• Needle Bar – At the end of the Needle Bar is the needle clamp unit, which of course holds the needle. Most Touch & Sew

Needle Bars have to lines inscribed on them. These are used for setting the overall needle depth.

• Position Finger – This plays a part in positioning the bobbin case correctly in the hook area. It also is held on with a left hand

thread. Don’t ever force it loose. Breaking this part will cause you major grief.

• Bobbin Case – Holds the bobbin

• Bobbin Winding Lever – When activated, it engages the hook driver and starts the bobbin winding process.

• Feed Dogs – Feeds the fabric through the machine sewing area

• Position Bracket – Like the position finger, it is used to adjust the position of the bobbin case in the hook area.

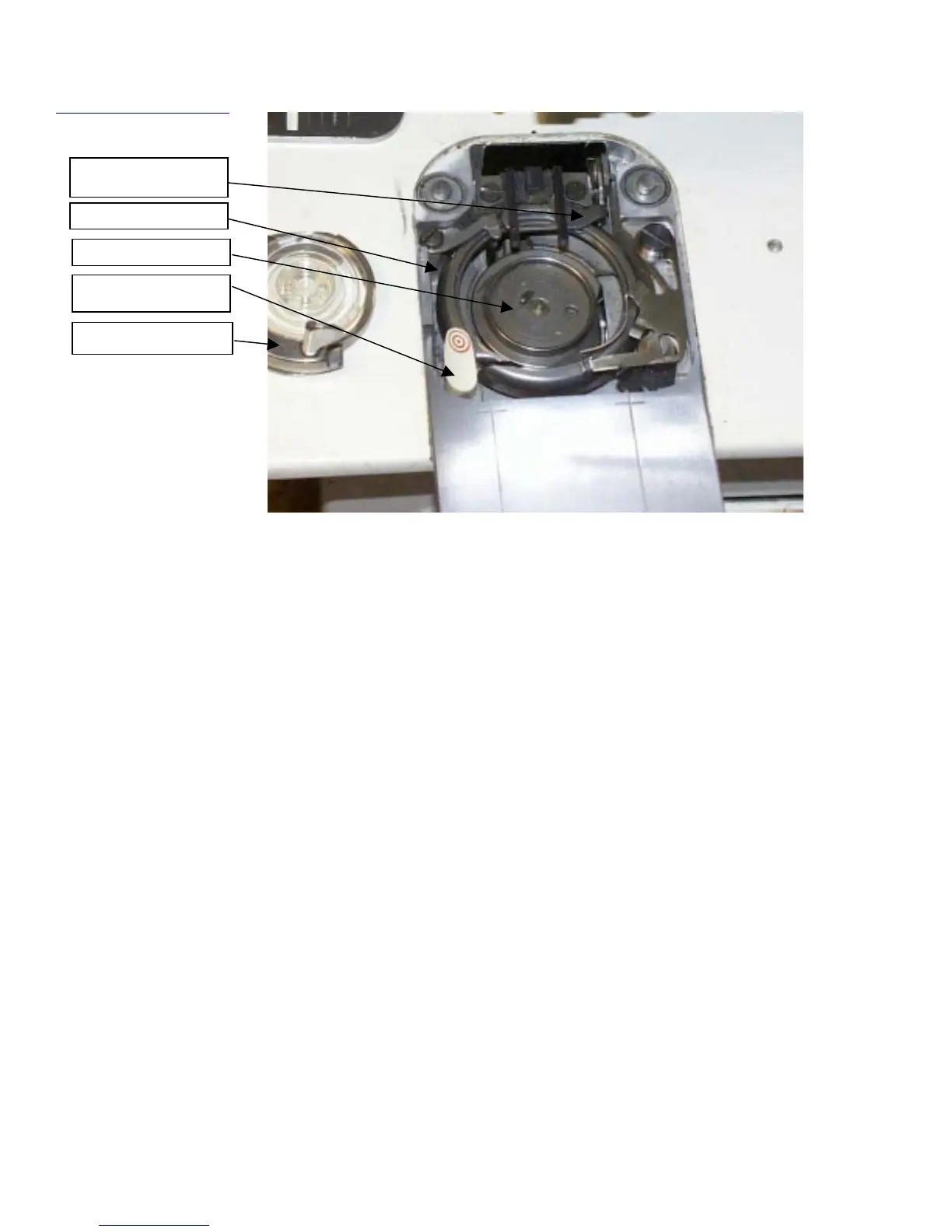

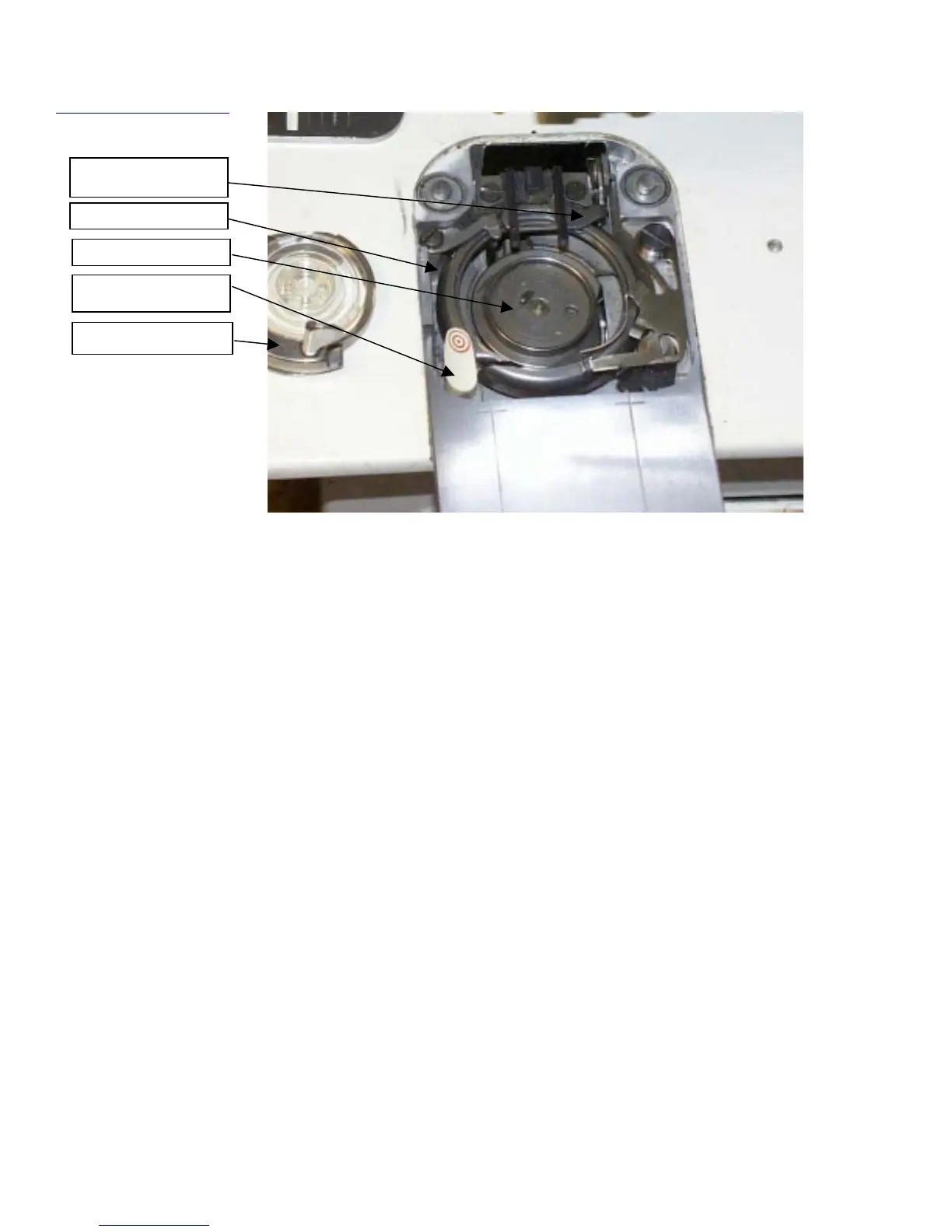

• Thread Pull Off Finger – Basically, keeps the thread from tangling around the feed dogs while sewing. This part is very

important, and has to be in proper working order. It is fastened to the machine in the bottom pan area. Generally you do not

need to remove it.

• Hook – Picks up the top thread and takes it around the bobbin thread. If this part is out of time in relation to the needle, the

machine will frequently drop stitches, or otherwise known as skipping stitches. Also if the point is damaged, it’ll case the

machine to break or fray the top thread while sewing. Depending on the damage, it may require replacement.

• Hook Driver – This part is what winds the bobbin. Any damage to this part, and it’s a pretty safe bet you’ll have bobbin

winding problems.

• Bobbin Winding Lever – When activated, it raises the hook driver and begins the bobbin winding function.

Pretty simple stuff, but all the parts must work together, and knowing the correct name will help you describe to your favorite

mechanic what you may think is wrong.

Thread Pull Off

Finger

Hook Driver

Bobbin Winder

Leve

Bobbin Case

Loading...

Loading...