n

A

n

B

n

C

n

D

2

One of the common reasons for unplanned downtime of belt-driven

machinery is pulley misalignment. Pulley misalignment can increase wear

on pulleys and belts as well as increasing the noise and vibration level

that can result in unplanned machinery downtime. Another side effect

of increased vibration is premature bearing failure. This too can cause

unplanned machinery downtime.

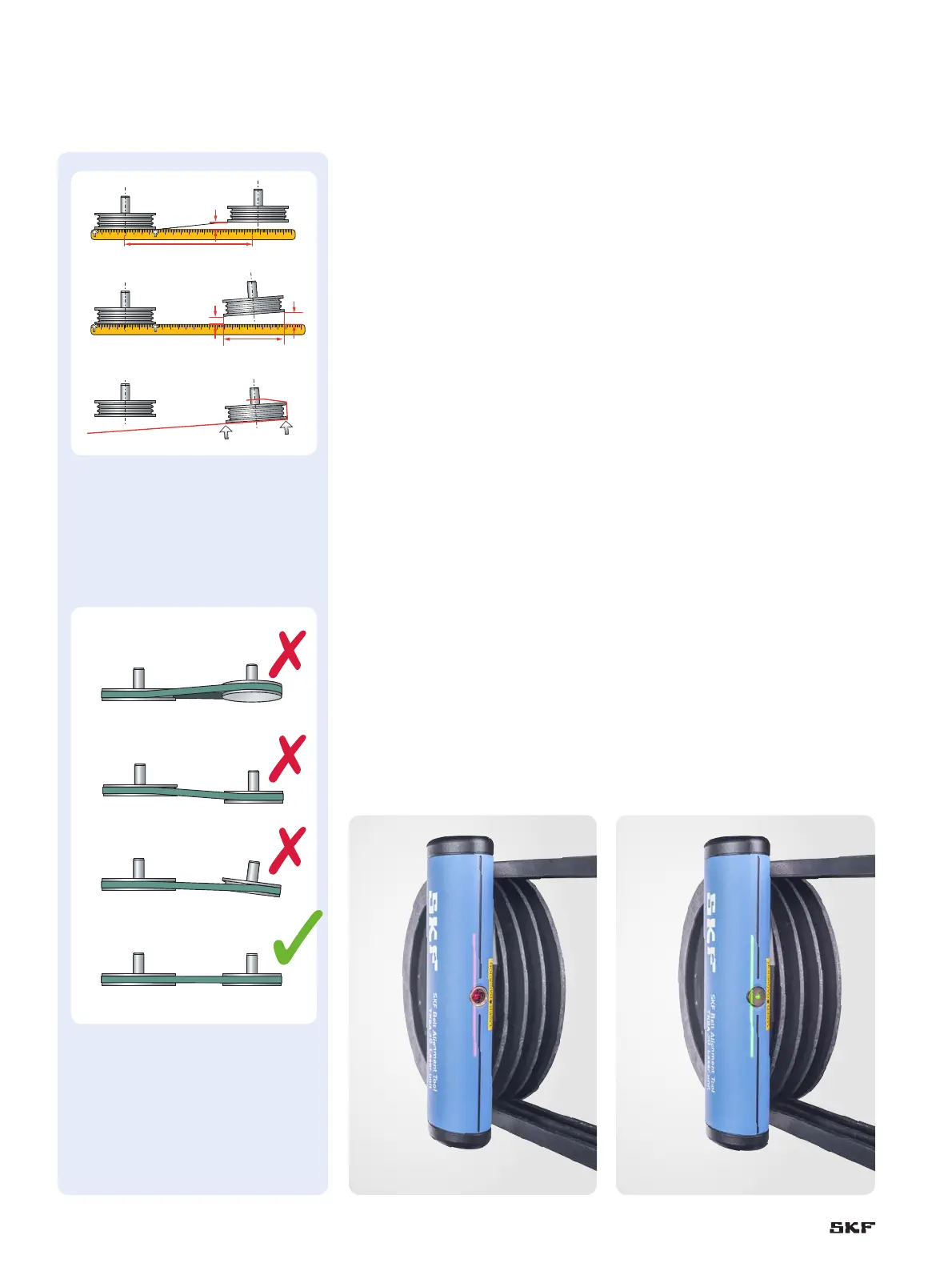

Traditional belt alignment methods

These methods are usually visual in combination with a straight edge

and/or length of string. Although quick to perform, they are often

inaccurate.

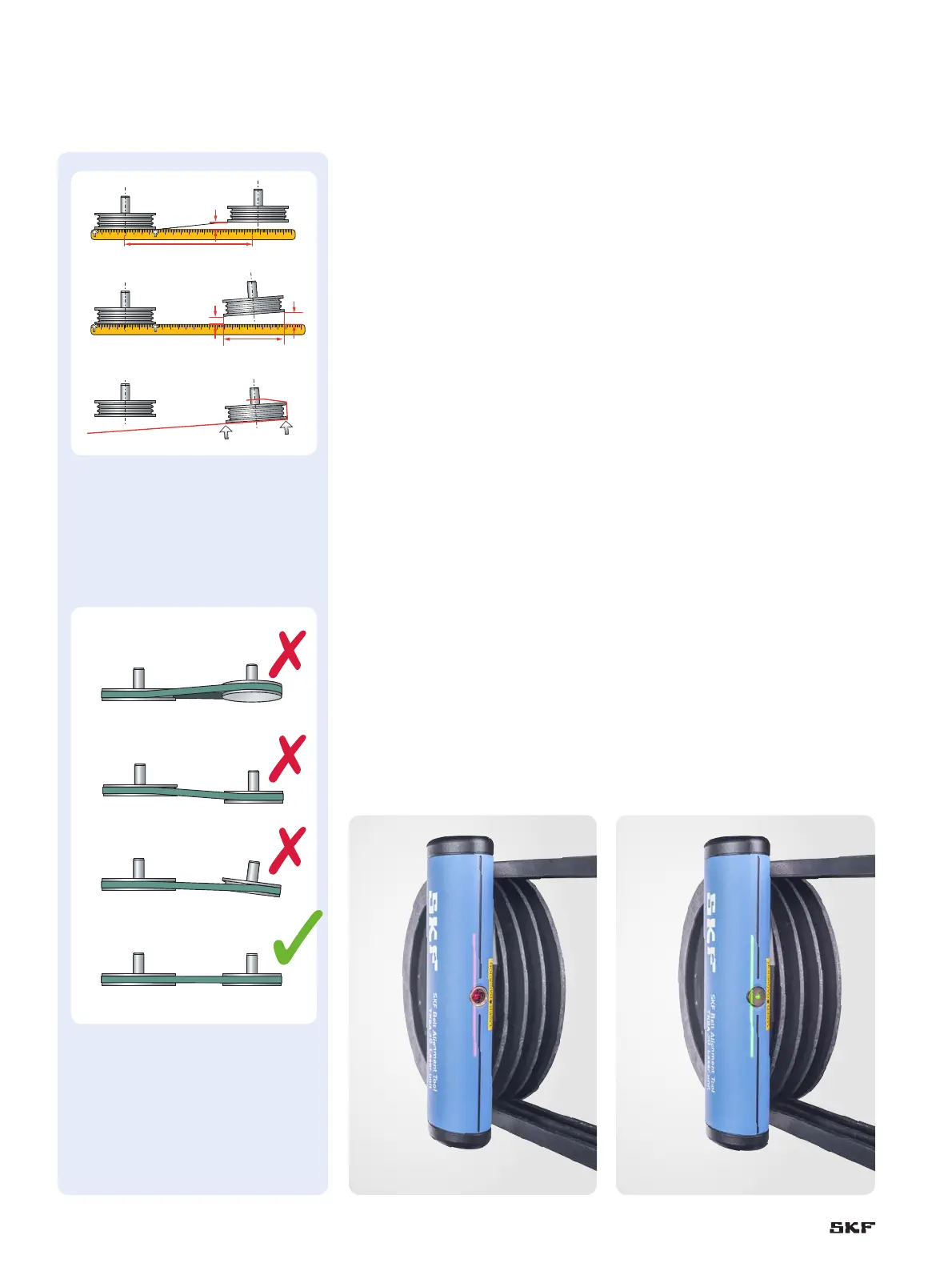

Laser belt alignment methods

Using a laser belt alignment tool is quicker and more accurate than

traditional methods. Belt alignment tools can either align the pulley

faces or the pulley grooves.

Accurate pulley and belt alignment can help you:

• Increase bearing life.

• Increase machinery uptime, efficiency and productivity.

• Reduce wear on pulleys and belts.

• Reduce friction and thereby energy consumption.

• Reduce noise and vibration.

• Reduce costs of replacing components and machinery downtime.

Measuring parallel and angular

misalignment using a straight edge

or a piece of string.

n

A

Vertical angle misalignment.

n

B

Parallel misalignment.

n

C

Horizontal angle misalignment.

n

D

Correct alignment.

SKF Belt Alignment Tools

TKBA 10 TKBA 20

Loading...

Loading...