Section 04 ENGINE

Sub-Section 03 (599 AND 779 ENGINE TYPES)

04-03-5

RAVE System

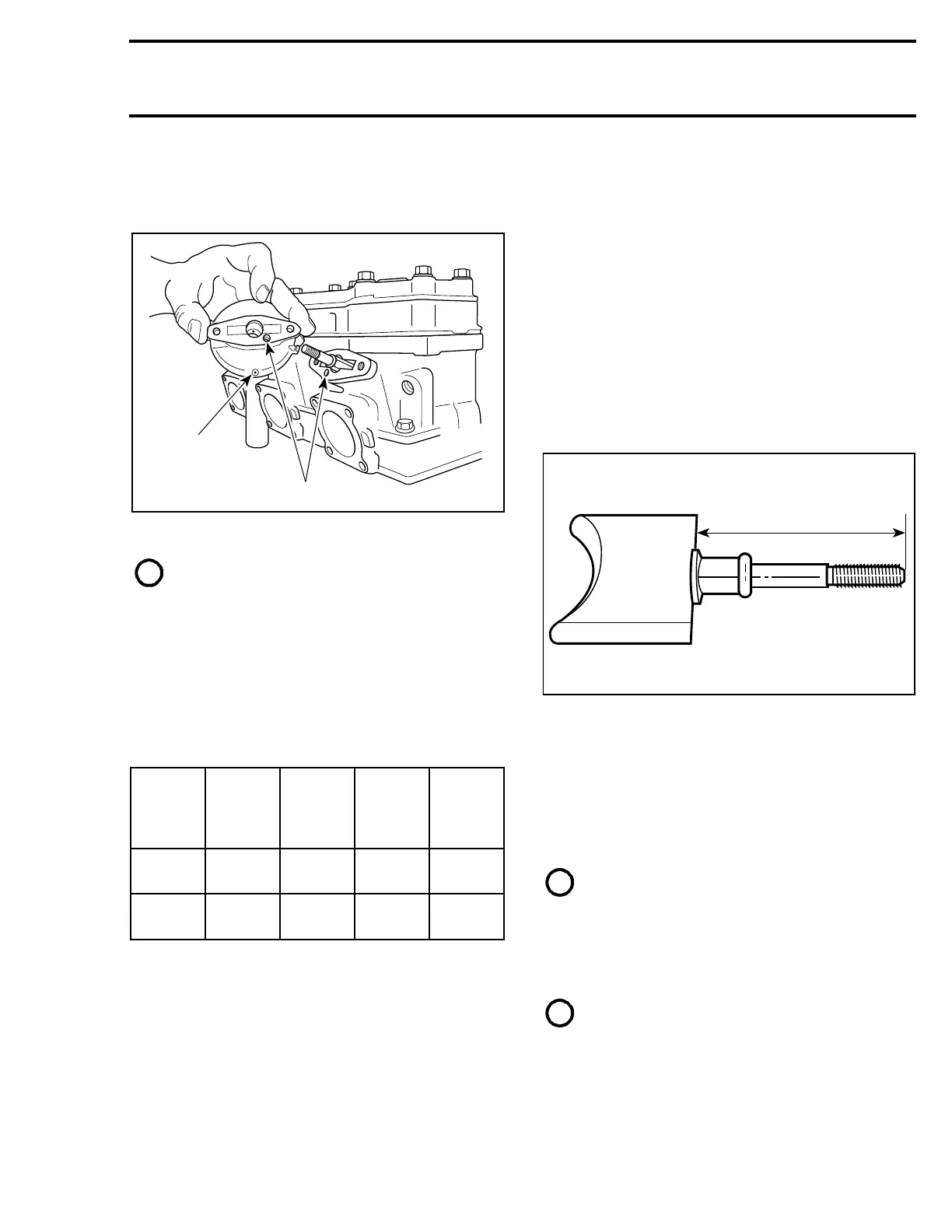

Check valve rod housing and cylinder for clogged

passages.

1. Draining hole

2. Passages

NOTE : Oil dripping from draining hole indi-

cates a loosen clamp or damaged bellows.

10, Valve Rod

Check valve rod for straightness.

15, Bellows

Check for cracked, dried or perforated bellows.

5, Spring

ASSEMBLY

RAVE SYSTEM

779 Only

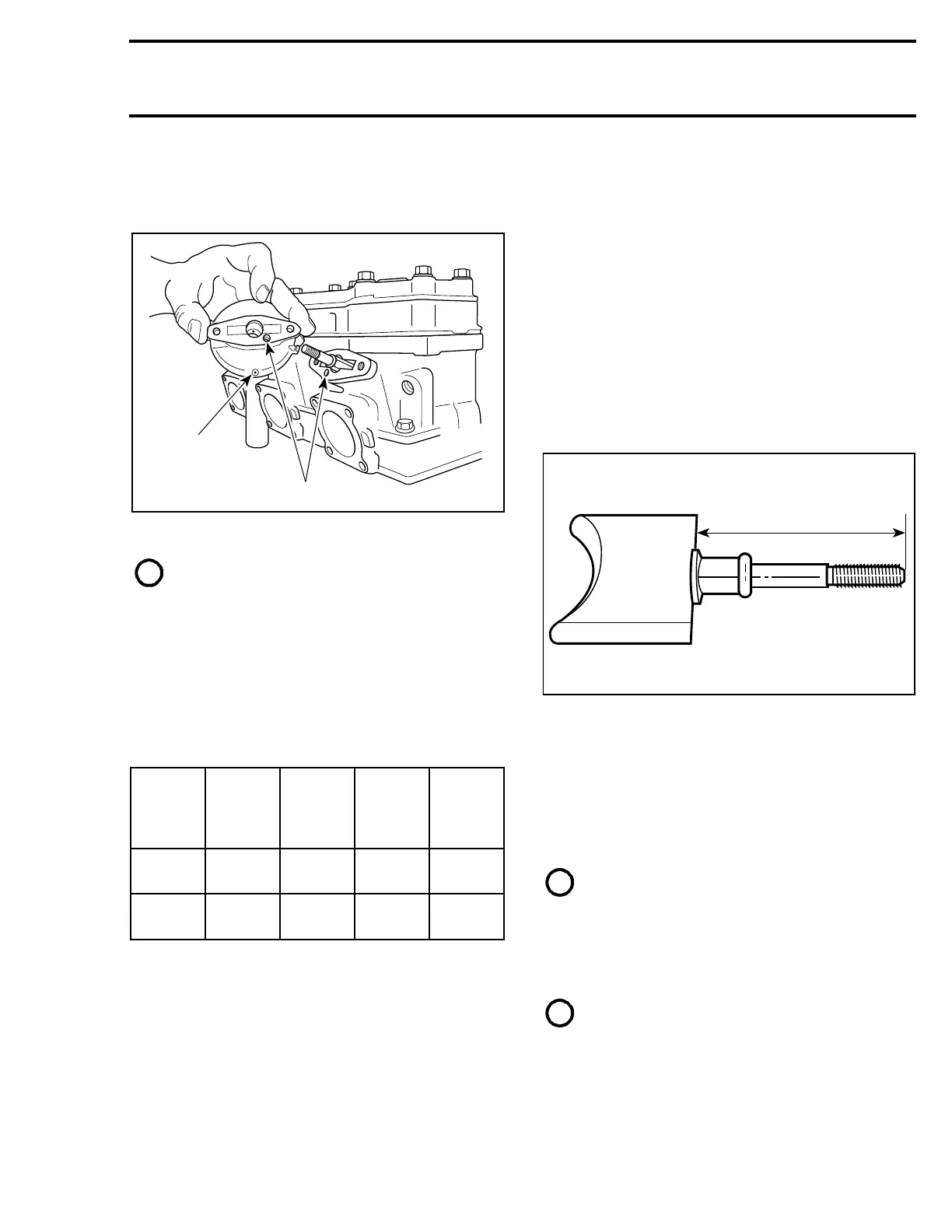

10,11,12,13,14, Valve Rod, O-ring,

Washer, Distance Nut and Exhaust Valve

Fully screw distance nut, with its notch first, on

valve rod longer threaded portion. Install washer

and apply high temperature threadlocker (P / N

420 8997 88) on threads. Screw valve rod into ex-

haust valve until following distance is respected.

Distance between RAVE valve and valve rod end

is 58 mm + 1 mm (2.283 + .039 in)

779 ENGINE ONLY

A. 58 + 1 mm (2.283 + .039 in)

Back off distance nut to jam the assembly. Install

O-ring. Install exhaust valve assembly in cylinder

with letters TOP facing upwards.

All Engines

Piston and Cylinder

NOTE : Be sure to restore the chamfer

around all cylinder sleeve port openings.

Before inserting piston in cylinder, lubricate the

cylinder with new injection oil or equivalent.

Install ring compressor (P / N 420 8769 74) on pis-

ton assembly.

NOTE : The ring compressor will not fit on

over size pistons.

ENGINE

TYPE

SPRING

P/N

Wire

Dia.

mm

(in)

Free

length

mm

(in)

Spring

Rate

N/mm

(lbs / in)

599

420

2399 40

0.8

(.031)

48.5

(1.91)

0.30

(1.71)

779

420

2399 41

0.8

(.031)

52.5

(2.17)

0.30

(1.71)

A06C0PA

2

1

Loading...

Loading...