Section 04 ENGINE

Sub-Section 05 (CDI SYSTEM)

04-05-8

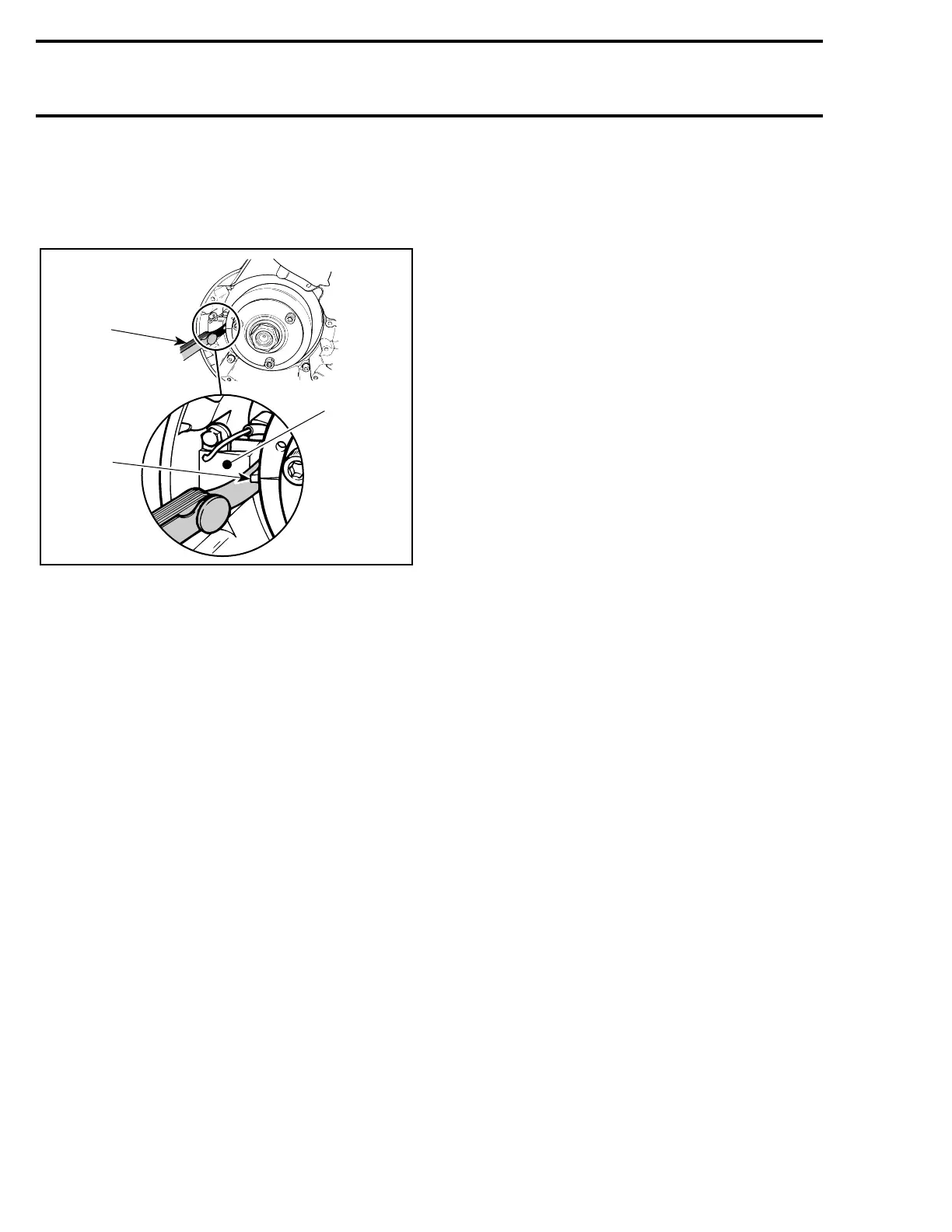

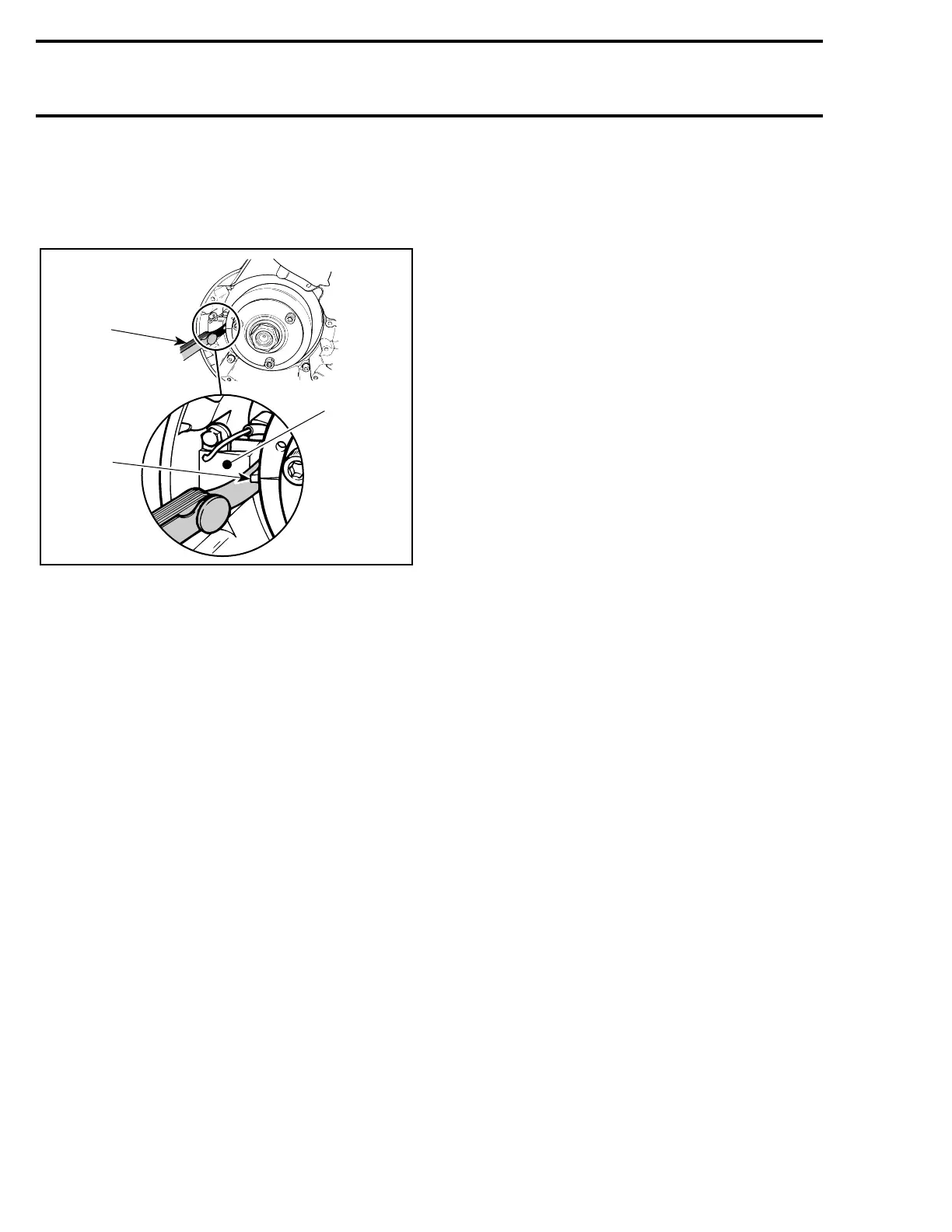

3.If necessary, adjust by slackening retaining

screws and moving trigger coil toward or away

of protrusion.

4. Retighten screws and recheck air-gap.

ADJUSTING TRIGGER COIL AIR-GAP

1. Measure at center pole of trigger coil min. 0.45 mm (.018) max.

0.55 mm (.022 in)

2. Trigger coil

3. Flywheel protrusion

1, Armature with Armature Plate

To replace armature :

– Disconnect the 2-wire connector (GREEN and

WHITE wires).

– Disconnect both YELLOW / BLACK and YEL-

LOW wires.

– Remove grommet from crankcase where mag-

neto harness exits magneto housing.

– Remove armature plate retaining screws.

– Remove armature plate with armature and

carefully pull wires.

– Install new parts and other parts removed.

ASSEMBLY

2,3, Magneto Flywheel and Nut

Clean crankshaft extension (taper).

Apply Loctite 242 (blue) on taper.

Position Woodruff key, flywheel and lock washer

on crankshaft.

Clean nut threads and apply Loctite 242 (blue) be-

fore tightening nut to 105 N•m (77 lbf•ft).

At reassembly coat all electric connections with

silicone dielectric grease (P / N 413 7017 00) to

prevent corrosion or moisture penetration.

CAUTION : Do not use silicone “sealant”,

this product will corrode contacts.

Ignition Timing

Check as described in IGNITION TIMING 06-02.

A25E0UA

1

2

3

-

Loading...

Loading...