Section 04 ENGINE

Sub-Section 06 (OIL INJECTION SYSTEM)

04-06-6

CHECKING OPERATION

On Vehicle

NOTE : Main oil line must be full of oil. See

bleeding procedure above.

Lift rear of vehicle and support with a mechanical

stand. Unbolt banjo fittings from pump. Start en-

gine and stop it as soon as it fires.

Check that oil level in small oil lines is passed ban-

jo fittings end by about 25 mm (1 in) (this will be

indicated by a clear section of small oil lines of

about 25 mm (1 in)). Repeat the procedure until

this condition is attained.

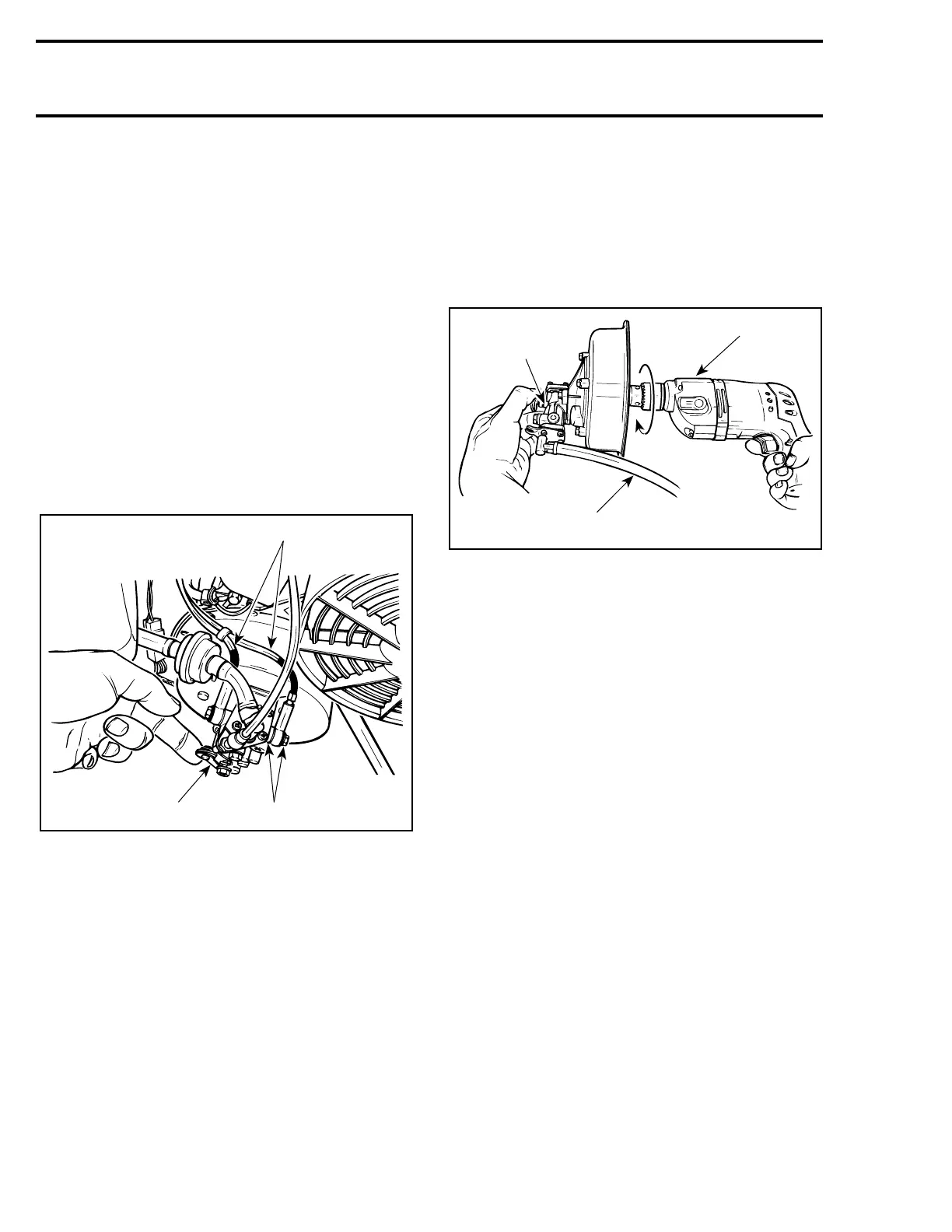

Reconnect banjo fittings with a washers on each

side, start engine and run at idle while holding the

pump lever in fully open position. Oil columns

must advance into small oil lines.

TYPICAL - ENGINE AT IDLE

1. Oil columns advancing

2. Washer on each side

3. Fully open position

If not, remove pump assembly and check the

pump gear and drive shaft (if applicable) for de-

fects, replace as necessary. Test pump as de-

scribes below.

NOTE : Through normal use, oil level must

not drop in small tubes. If oil drops, verify

check valve operation in banjo fittings. For 599 en-

gine check valve is integrated in injection nozzle.

For 779 check valve is in oil line. Replace as nec-

essary.

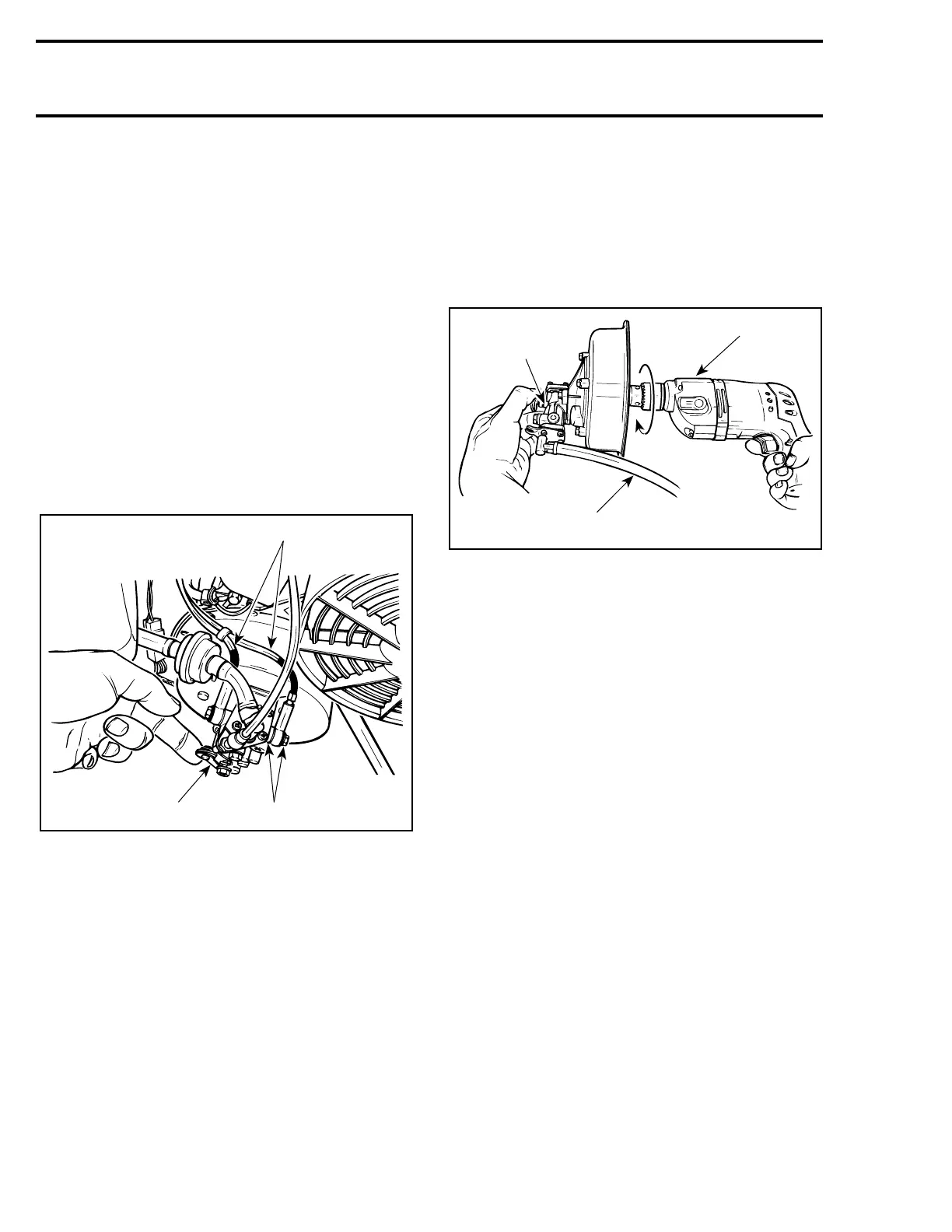

Oil Pump Test Bench

Connect a hose filled with injection oil to main line

fitting. Insert other hose end in an injection oil

container. Using a counterclockwise rotating drill

rotate pump shaft. Oil must drip from outer holes

while holding lever in a fully open position. If not

replace pump.

TYPICAL

1. Fully open position

2. Counterclockwise rotating drill

3. Main line

'

A15C17A

1

23

'

A15C18A

2

1

3

Loading...

Loading...