Section 04 ENGINE

Sub-Section 07 (AXIAL FAN COOLING SYSTEM)

04-07-3

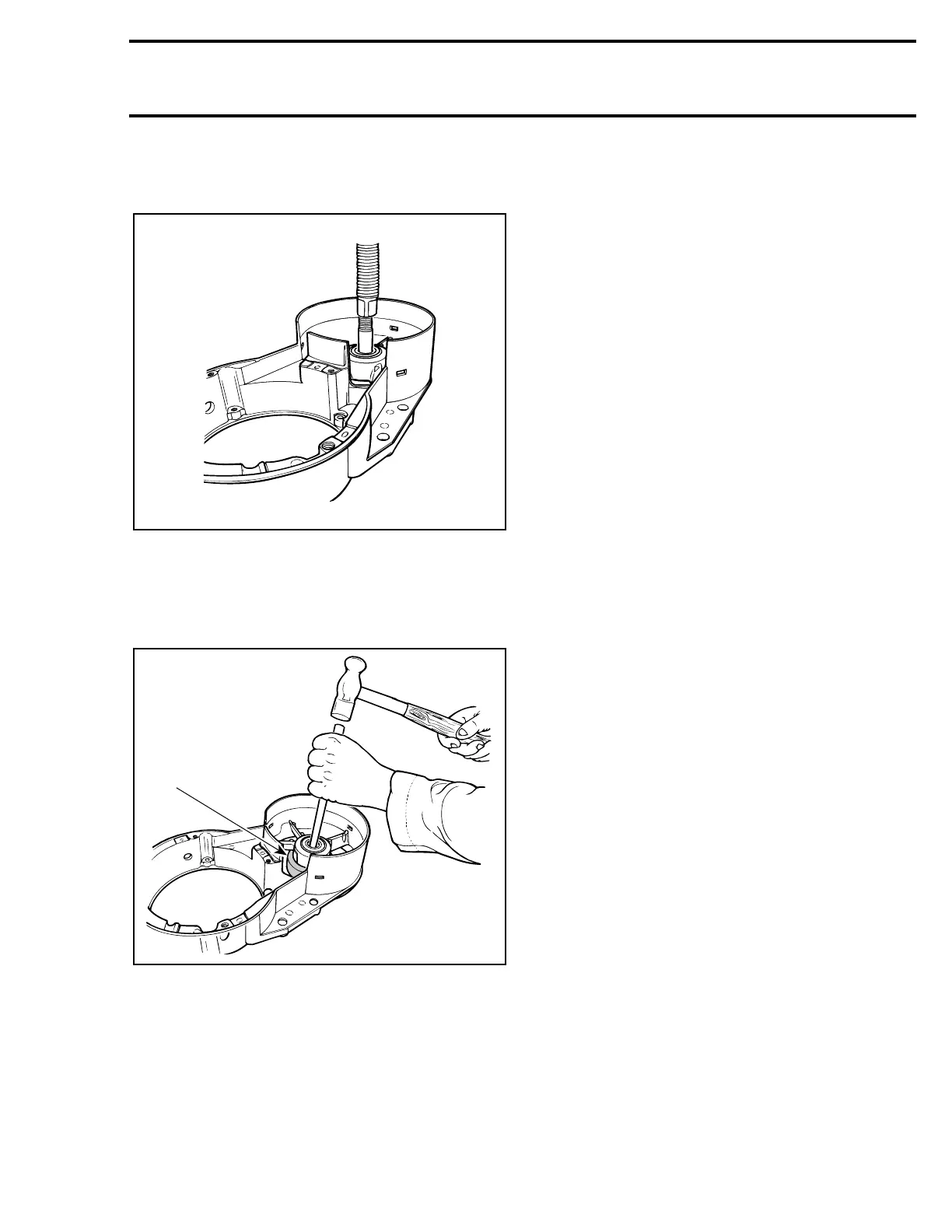

9, Fan Shaft

Using a press, drive the fan shaft out.

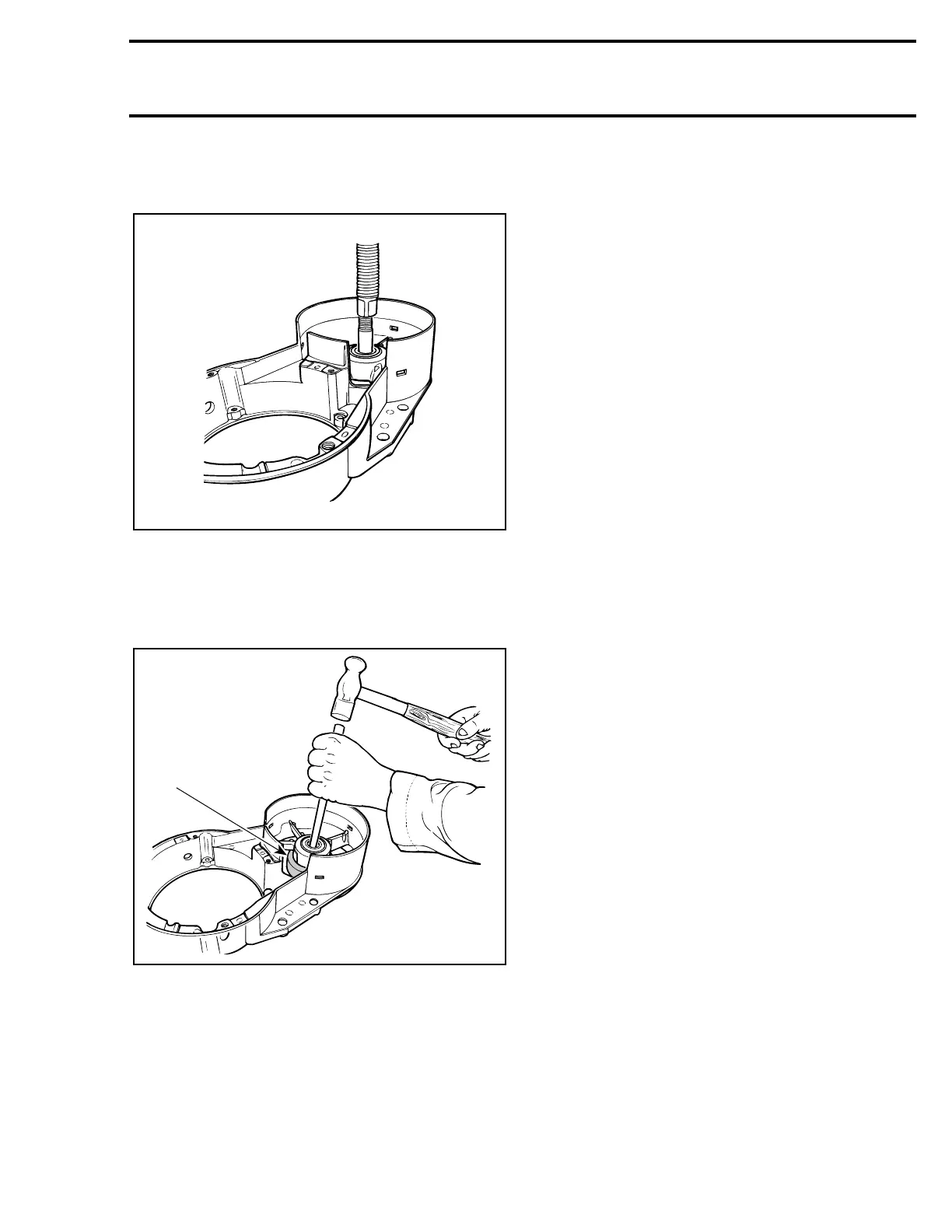

10,12, Bearing and Fan Housing

Support fan housing with a ring. With a punch,

working all around bearing inner race, drive bear-

ing out of fan housing. Keep shims for installation.

1. Ring supporting fan housing

10,11, Bearing and Circlip

Remove circlip then remaining bearing.

To install, press one bearing in place then install

circlip and shims. Press the other bearing from op-

posite side until it is flush with housing. Press fan

shaft from engine side of fan housing. Check for

free rolling action.

1,2,3, Screw, Loctite 242 (Blue) and

Cylinder Cowl

At assembly, apply a light coat of Loctite 242

(blue) on threads. It should be noted that to cor-

rectly remove a threadlocked screw, it is first nec-

essary to slightly tap on screw head to break

threadlocker bond. This will eliminate the possibil-

ity of screw breakage.

6,7,8, Rivet, Washer and Air Duct

Check for damage or permanent deformation.

Air duct can be removed by drilling out rivets.

CAUTION : At reassembly, use only

closed end rivets to avoid rivet ends from

falling into magneto.

Install washer over air duct.

On all engines, check fit of engine air duct with

hood air duct. Adjust hood as necessary.

4,5, Cylinder Cowl

A gasket must be placed on both sides (inner and

outer) of intake and exhaust holes of cylinder

cowl.

18, Fan Protector

Reinstall properly.

WARNING : Always reinstall fan protector

after servicing.

A23C06A

A23C07A

1

Loading...

Loading...