Section 04 ENGINE

Sub-Section 09 (ROTARY VALVE, COOLANT PUMP AND RESERVOIR)

04-09-7

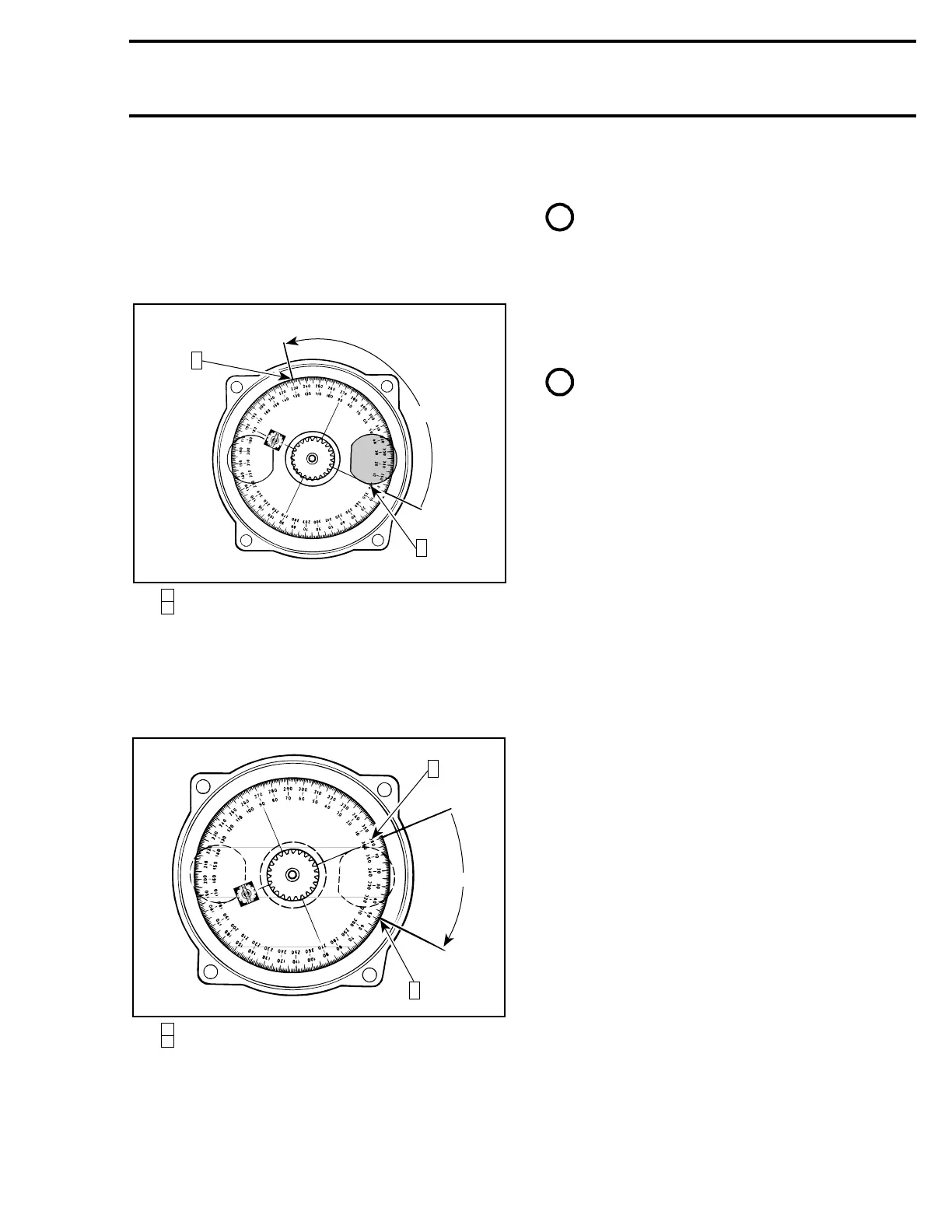

– Turning crankshaft, bring MAGneto side piston

to Top Dead Center as done before with a

crankcase having a ridge.

– For opening mark, first align 360° line of degree

wheel with BOTTOM of MAGneto side inlet

port. Then, find 132° line on degree wheel and

mark crankcase at this point.

Step : Align 360° line of degree wheel here

Step : Find 132° on degree wheel and mark here

1. Opening mark

2. Bottom of MAGneto inlet port

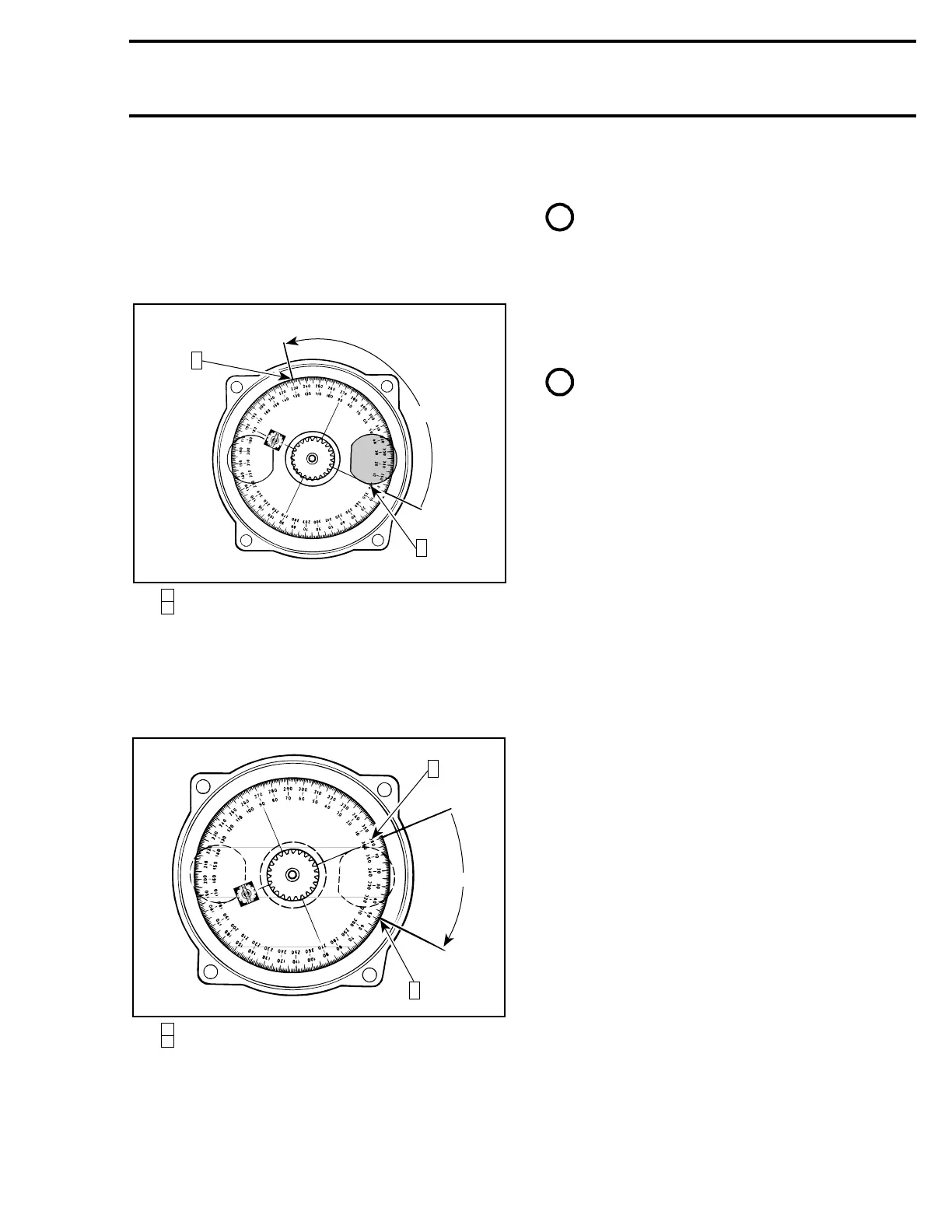

–For closing mark, first align 360° line of degree

wheel with TOP of MAGneto side inlet port.

Then, find 52° line on degree wheel and mark

crankcase at this point.

Step : Align 360° line of degree wheel here

Step : Find 52° on degree wheel and mark here

1. Top of MAGneto inlet port

2. Closing mark

– Position rotary valve on shaft splines to have

edges as close as possible to marks.

NOTE : Rotary valve is asymmetrical. There-

fore, try turning it inside out then reinstall on

splines to determine best installation position.

Apply injection oil on rotary valve before closing

rotary valve cover.

To Time Rotary Valve Exactly to

Specifications

NOTE : If desynchronization (out of spec.) is

unknown, install rotary valve to determinate

it before proceeding with the following.

First Method

Turn crankshaft to bring MAG piston to TDC.

Scribed marks of crankshaft and upper crankcase

must aligned. These marks were scribed while

determinating desynchronization.

Install brass gear on rotary valve shaft with its

marked spline 4 positions (splines) away for one

degree of desynchronization. Turn in the opposite

direction of desynchronization. For instance, a ro-

tary valve is retarded by 2.5°, turn brass gear by

10 splines counterclockwise.

Second Method

Turn crankshaft to bring MAG piston to TDC.

Scribed marks of crankshaft and upper crankcase

must aligned. These marks were scribed while

determinating desynchronization.

For each degree of desynchronization, rotary

valve shaft should be turned in the opposite direc-

tion by about 5 splines on the rotary valve gear.

Note position of rotary valve gear mark when

brass gear disengage worm gear of crankshaft at

removal of rotary valve shaft. From this position,

turn shaft accordingly then reinstall.

For instance, take a valve advanced by 2°.

132°

F01D2JA

1

2

1

2

1

2

52°

F01D2KA

1

1

2

2

1

2

Loading...

Loading...