Section 04 ENGINE

Sub-Section 11 (CARBURETOR AND FUEL PUMP)

04-11-6

CARBURETOR FLOAT LEVEL

ADJUSTMENT

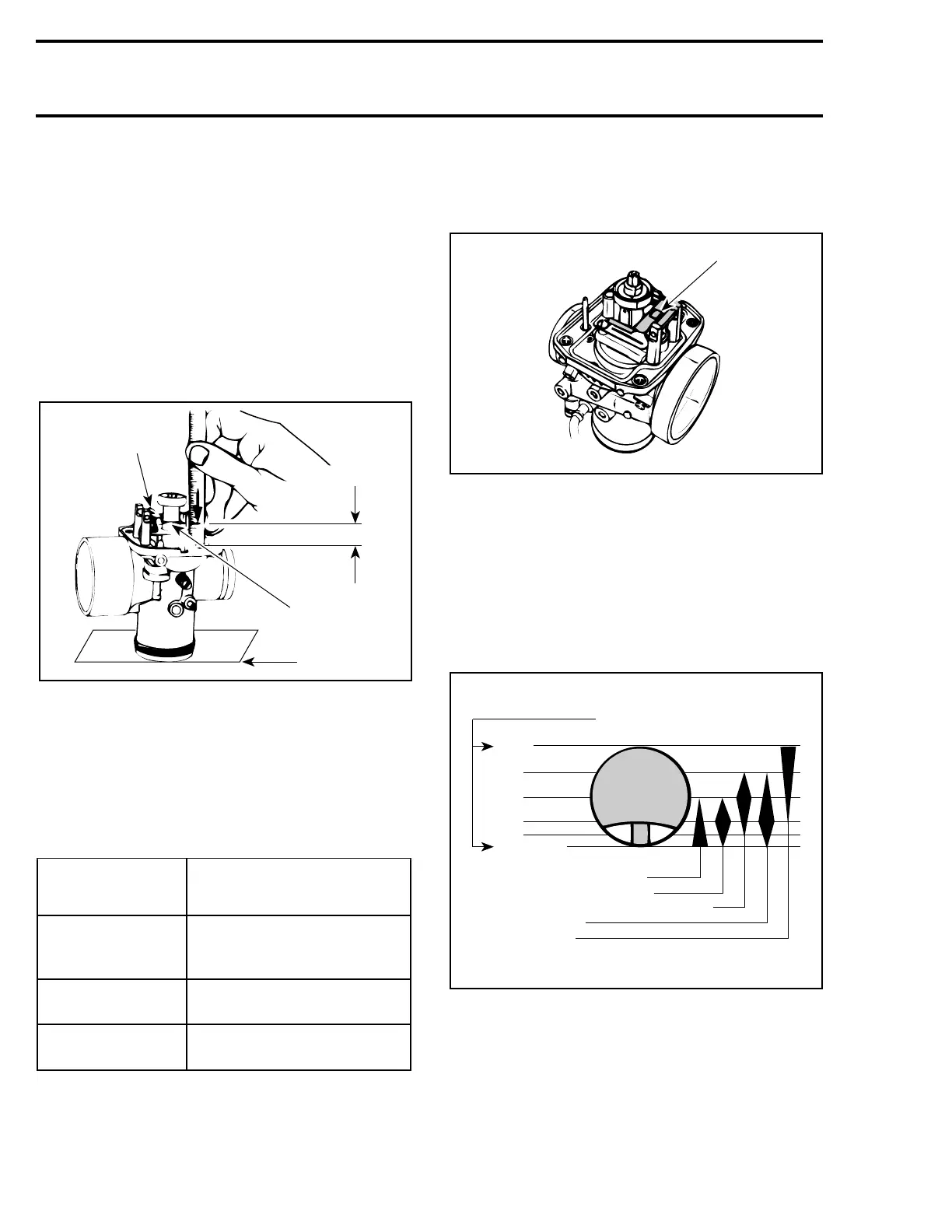

9,10, Float Arm and Float Arm Pin

Correct fuel level in float chamber is vital toward

maximum engine efficiency. To check for correct

float level proceed as follows :

– Remove float bowl and gasket from carburetor.

– With carburetor chamber upside-down on a lev-

el surface, measure height H between bowl

seat and top edge of float arm.

TYPICAL

1. Contact tab

2. Float arm

3. Level surface

4. H

On TM 38, do not turn carburetor up side down.

Measure float arm height when it just touches

needle valve without moving it.

Float arm height dimensions :

To Adjust Height H :

– Bend the contact tab of float arm until the spec-

ified height is reached.

1. Contact tab

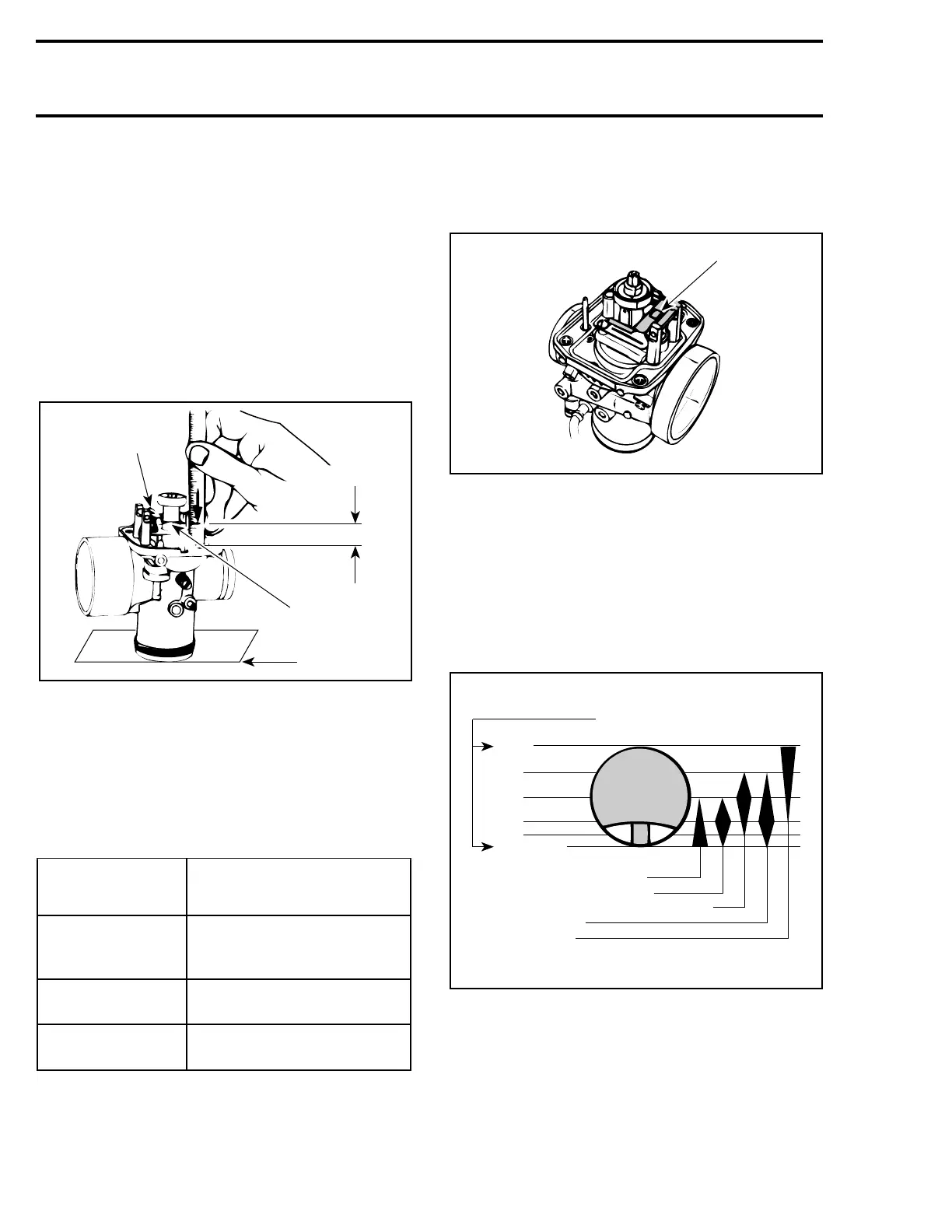

The illustration below shows which part of the

carburetor begins and to stops to function at dif-

ferent throttle slide openings.

Note that the wider part of symbol corresponds to

the opening mostly affected. For instance, throt-

tle slide cut-away begins to function at close posi-

tion but it is most effective at 1/4 opening and

decreases up to 1/2 opening.

NOTE : For fine tuning refer to TECHNICAL

DATA section 10 and to SPARK PLUG 06-03.

NOTE : For high altitude regions, the

High

Altitude Technical Data

(P / N 484 0624 00

and 484 0545 00 for binder) gives information

about calibration according to altitude and temper-

ature.

CARBURETOR

MODEL

FLOAT HEIGHT H

± 1 mm (± .040 in)

VM 32-269

VM 34-469

VM 34-470

23.9 (.941)

VM 38

VM 40

18.1 (.713)

VM 38 (Summit)

VM 40 (Summit)

19.6 (.772)

A00C02A

A

1

2

3

A00C03A

1

Throttle slide openings

Wide

open

3/4

1/2

1/4

1/8

Close

Pilot jet and air screw13,6,

Throttle slide cut-away5,

Needle taper and needle position3,

Needle jet14,

Main jet8,

A00C04A

'

'

Loading...

Loading...