Section 06 ELECTRICAL

Sub-Section 02 (IGNITION TIMING)

06-02-1

IGNITION TIMING 2

NIPPONDENSO TRIGGER COIL SYSTEM

454, 583, 599, 670 and 779 Engine Types

Ignition timing is adjusted by movement of trigger

coil. Raising position of trigger coil retards igni-

tion. Lowering position of trigger advances igni-

tion. On 454 and 670 engines, moving trigger coil

to right retards ignition and moving to left advanc-

es ignition.

CAUTION : Each time ignition timing is

adjusted by moving trigger coil, air-gap

must be adjusted.

Refer to CDI MAGNETO 04-05 then look for Trig-

ger Coil Adjustment after adjusting ignition tim-

ing.

Verifying Magneto Flywheel Timing

Mark Position

Prior to checking the timing, it may be necessary

to verify the position of the timing mark on the

magneto flywheel, for the following reasons :

1. To detect a missing or broken magneto fly-

wheel Woodruff key which would allow a

change of timing to occur, with eventual break

down of the engine.

2. To correctly locate and mark a timing mark on a

new service magneto flywheel.

3. To verify the correct location of the factory tim-

ing mark.

4. To detect a wrong magneto flywheel.

To verify the position of the timing mark on the

magneto flywheel or to scribe a timing mark, pro-

ceed as follows :

1. Clean the area around the spark plugs, and re-

move them.

2. Remove the rewind starter from the engine.

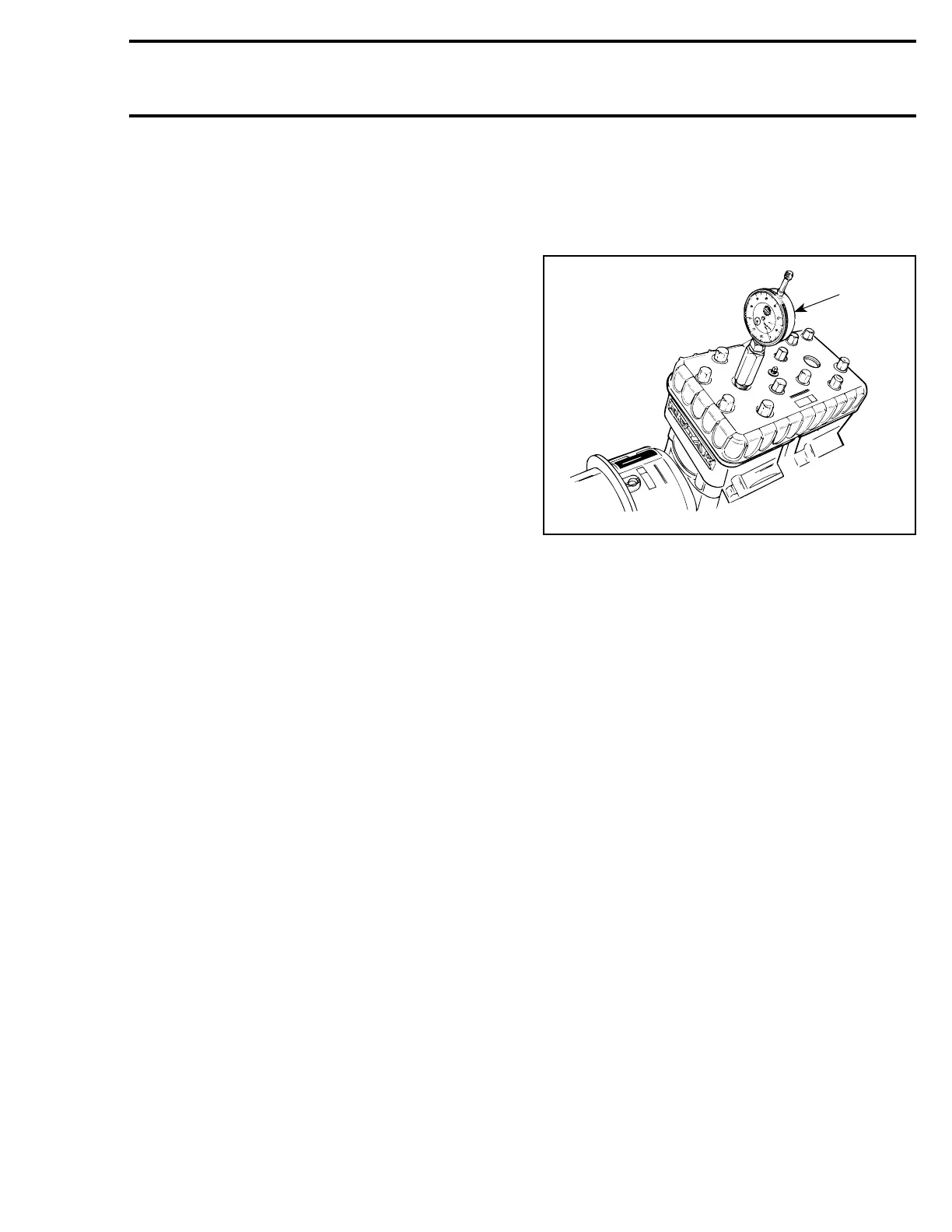

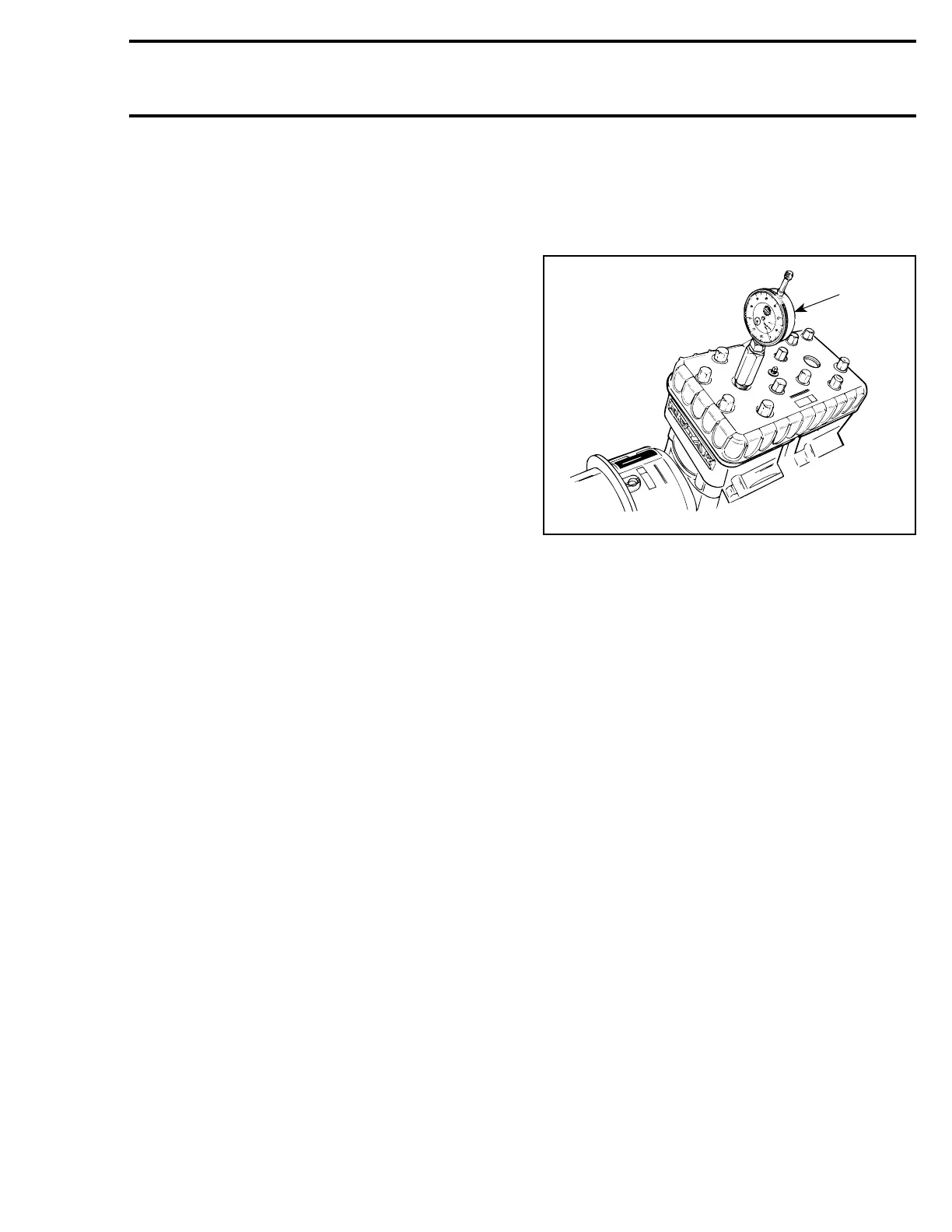

3. Install the TDC gauge in the spark plug hole,

(magneto side) and adjust as follows :

a. Position the magneto flywheel at approxi-

mately TDC.

TYPICAL

1. TDC gauge MAG side

b. Assemble the gauge to the adaptor and tight-

en the roller lock nut. Do not tighten the

adaptor lock nut.

c. Screw the adaptor into the spark plug hole

and tighten to prevent movement in the plug

hole.

d. Position the dial face toward the magneto.

Move the gauge down until the needle just

begins to move, then move down a further 5

or 6 mm (approximately 1/4 in). Tighten adap-

tor lock nut by hand.

4. Locate the piston TDC position as follows :

a. Slowly rotate the magneto flywheel back and

forth across TDC while observing the needle.

Note that the needle stops moving only as

the piston is changing direction.

b. Rotate the dial face so that “0” is in line with

the needle when it stops moving.

c. Again, slowly rotate the magneto flywheel

back and forth across TDC and adjust the dial

face to “0”, until the needle always stops ex-

actly at “0” before changing direction.

d. “0” now indicates exact TDC.

5. Verify the position of the timing mark on the

magneto flywheel as follows :

Loading...

Loading...