Section 07 REAR SUSPENSION

Sub-Section 03 (IMPROVED C-7 SUSPENSION)

03-03-3

Position notch in outer spacer forward and inward

onto the rear axle.

10,12,13,14,15, Screw

Clean all screw threads and axle hole threads. Pri-

or to assembly, apply low temperature grease (P /

N 413 7061 00) on axles and Loctite 271 (P / N

413 7074 00) on screw threads.

11, Elastic Stop Nut

Inspect for damage and replace as required.

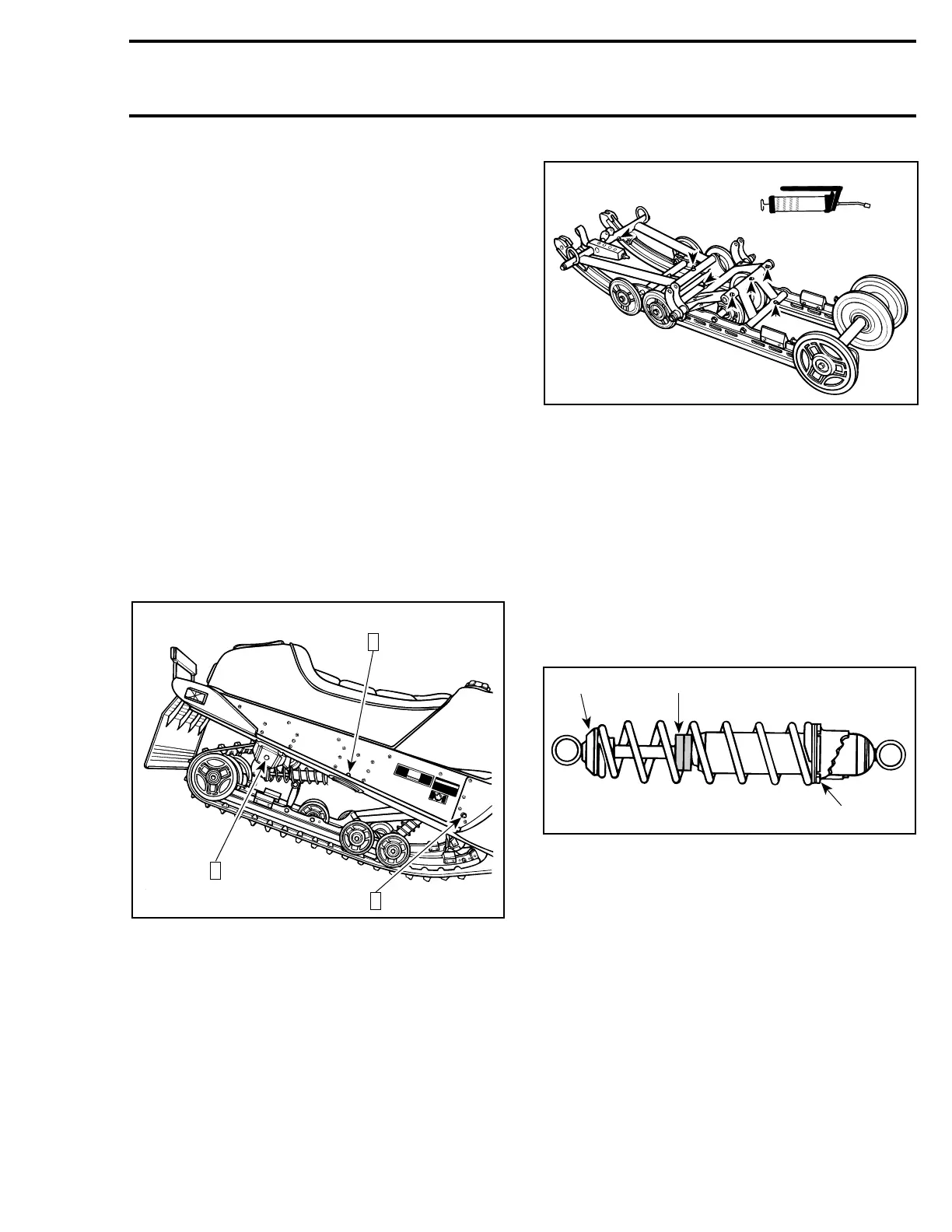

INSTALLATION

CAUTION : Close fuel shut-off valve(s) be-

fore lifting vehicle.

Lift rear of vehicle off the ground about 850 mm

(33-1/2 in). Install assembled suspension into

track with front portion first. Insert rear portion of

suspension into track.

Bolt suspension to tunnel following sequence and

torque values as follows.

TYPICAL

A. 48 N•m (35 lbf•ft)

16, Grease Fitting

Lubricate until grease appears at joints using low

temperature grease (P / N 412 7061 00) :

– Front arm : upper and lower axles.

– Rear arm : upper and lower axles.

– Rear shackle.

NOTE : There are 7 lubrication points.

TYPICMAL

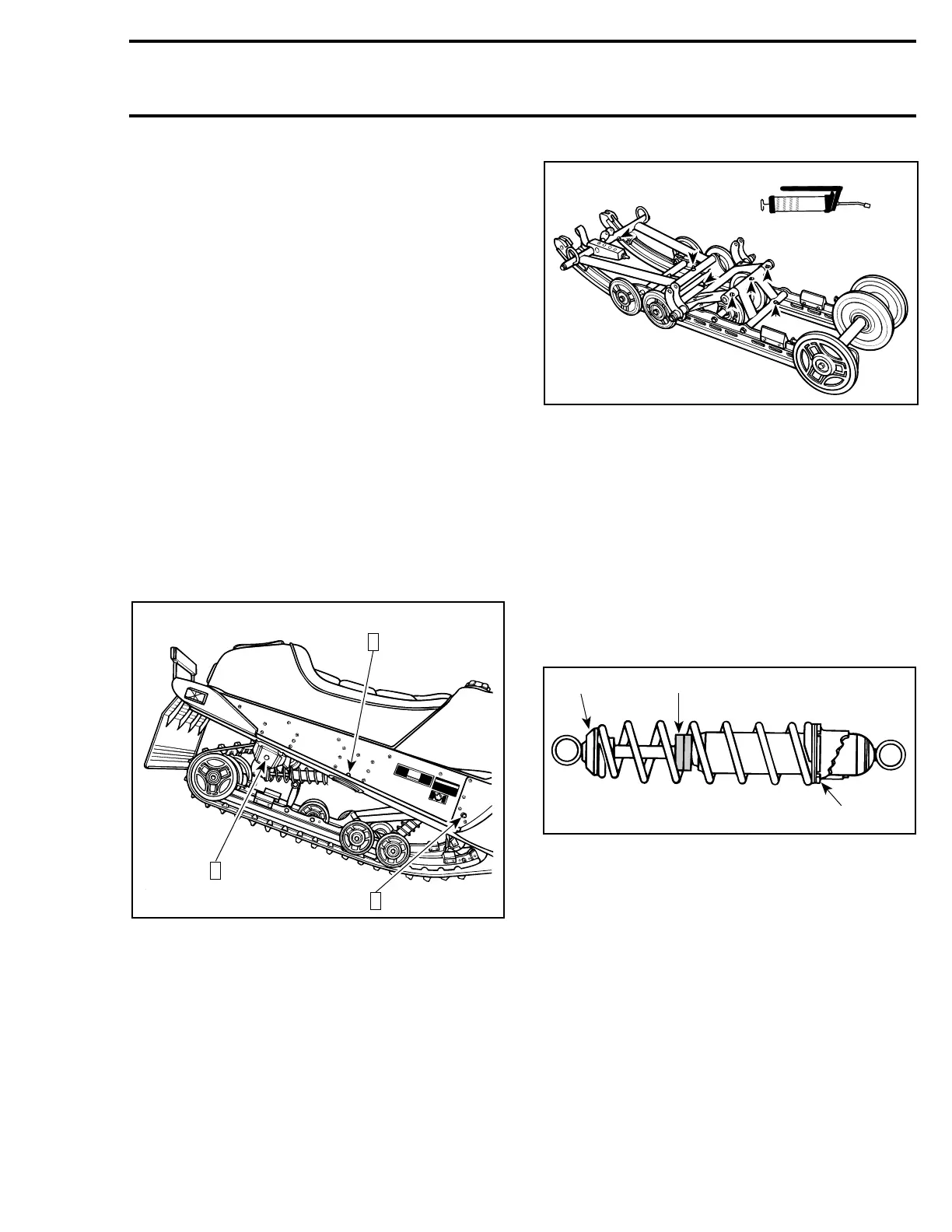

SHOCK ABSORBER SPRING

REPLACEMENT

WARNING : Do not attempt to dismantle a

shock absorber spring without using the

proper spring compressor. Do not apply heat

or flame to the rear gas pressurized shocks.

NOTE : Before attempting to compress the

spring, push the rubber bumper against the

shock body and place the adjuster ring at its low-

est position.

TYPICAL

1. Spring collar

2. Bumper against shock body

3. Lowest position

Install spring compressor (P / N 529 0271 00) in a

vise. Mount shock in it and turn shock so that

spring coils matched spring compressor.

Close and lock bar. Adjust handle horizontal by

changing position of clevis pin.

Push down on handle until it locks. Remove

spring stopper then release handle.

A06F05B

3

A

2

A

1

A

'

A06F08A

Loading...

Loading...