Section 07 REAR SUSPENSION

Sub-Section 05 (TRACK)

07-05-1

TRACK 5

TRACK TYPE APPLICATION

Refer to TECHNICAL DATA section10.

GENERAL

This section gives guidelines for track removal.

Some components require more detailed disas-

sembly procedures. In these particular cases, re-

fer to the pertaining section in this manual.

INSPECTION

Visually inspect track for :

– cuts and abnormal wear

– broken rods

– broken or missing track cleats

If track is damaged or rods are broken, replace

track. For damaged or missing cleats, replace by

new ones, using cleat remover (P / N 529 0287

00). Use small-cleat installer (P / N 529 0085 00).

WARNING : Do not operate a snowmobile

with a cut, torn or damaged track.

REMOVAL

S Series and F Series

Remove the following parts :

– speedometer cable

– muffler

– chaincase cover

– suspension

– drive axle seal

– end bearing housing

– sprockets and chain

– drive axle (toward end bearing housing)

– track

Skandic WT

Remove the following parts :

– rear suspension

– muffler

– RH drive axle end bearing

– angle drive and square pin

Move transmission sideway. Do not remove

brake mechanism nor driven pulley. Refer to

SKANDIC WT SUSPENSION 07-02.

Remove drive axle then track.

INSTALLATION

All Models

Reverse the removal procedure.

NOTE : When installing the track, respect

rotation direction indicated by an arrow on

track thread.

Check sprocket / track alignment as described in

DRIVE AXLE 07-04.

Track Tension and Alignment

Track tension and alignment are inter-related. Do

not adjust one without checking the other. Track

tension procedure must be carried out prior to

track alignment.

Tension

Lift the rear of vehicle and support with a mechan-

ical stand. Allow the slide to extend normally.

Check the gap half-way between front and rear

idler wheels. Measure between slider shoe and

bottom inside of track.

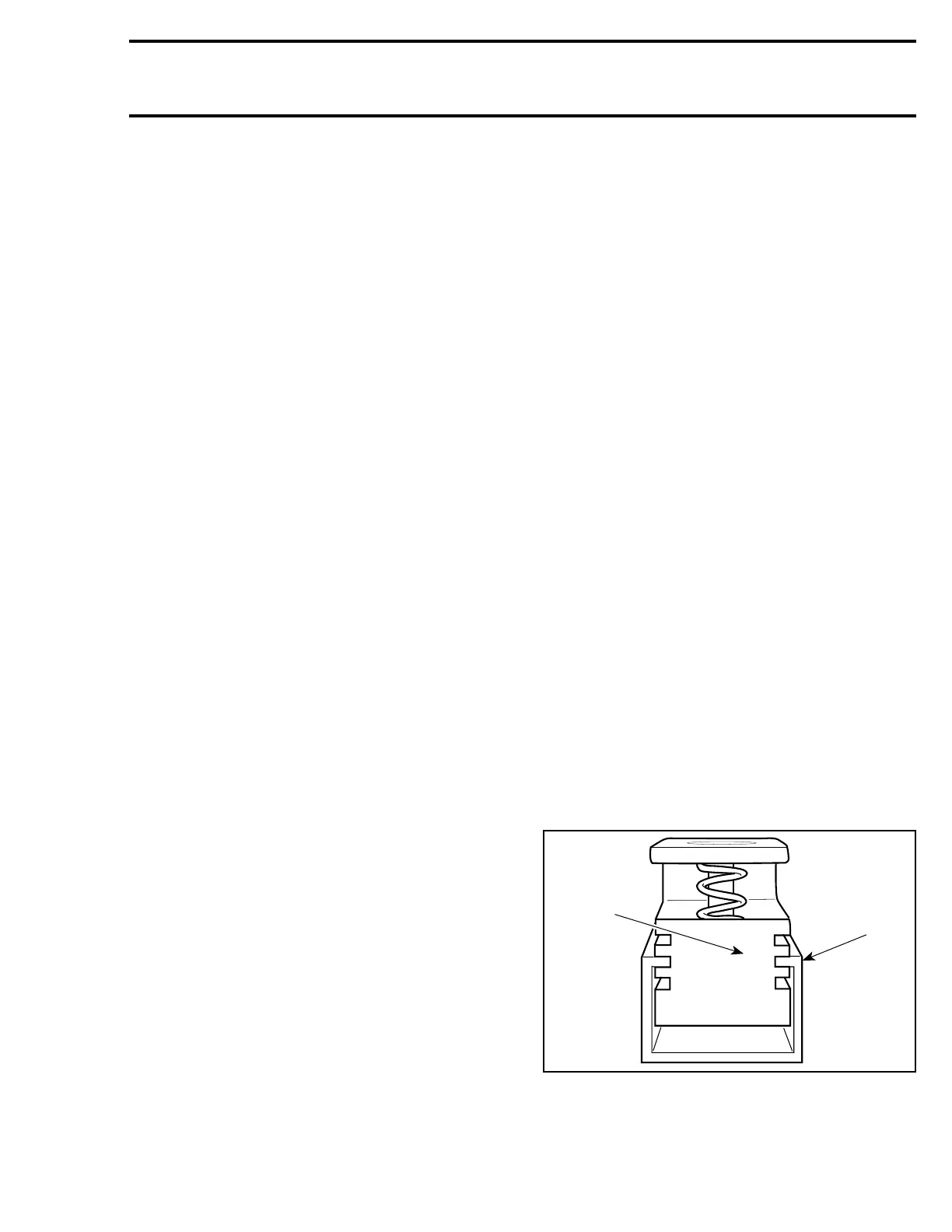

When using the track tension gauge (P / N 529

0215 00), slide U shape extrusion to proper de-

flection.

1. Example 45 mm

2. Extrusion

;

Loading...

Loading...