Section 04 ENGINE

Sub-Section 01 (503 ENGINE TYPE)

04-01-5

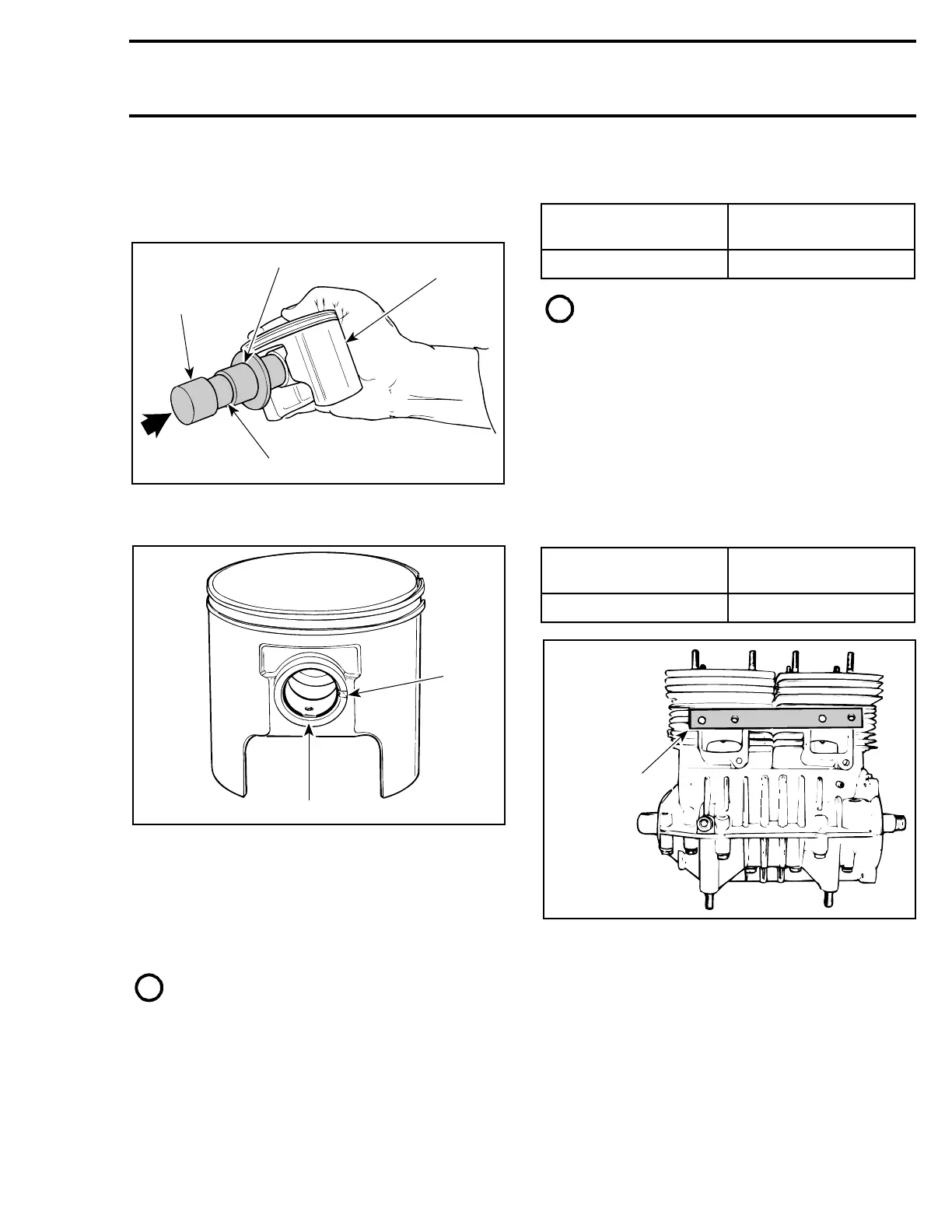

To minimize the effect of acceleration forces on

circlip, install each circlip so the circlip break is at

6 o’clock as illustrated. Use piston circlip installer

(P / N 529 0086 00).

1. Place circlip in

2. Restrain

3. Oil

1. Piston notch

2. Circlip break at 6 o’clock

CAUTION : Circlips must not move freely

in the groove after installation. If so, re-

place them.

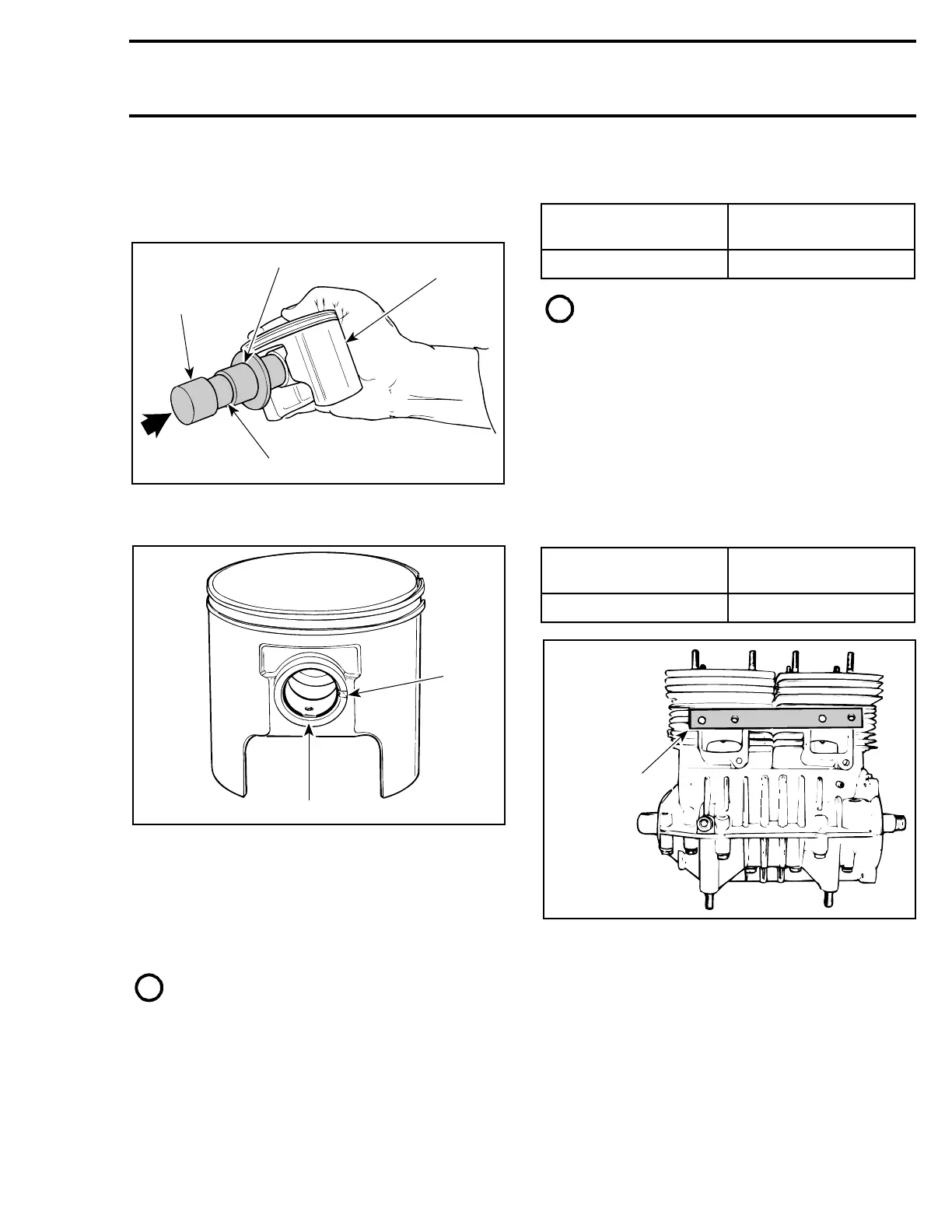

7,15, Cylinder and Piston

NOTE : Be sure to restore the chamfer

around all cylinder sleeve port openings.

Before inserting piston in cylinder, lubricate the

cylinder with new injection oil or equivalent.

Install proper ring compressor on piston assem-

bly.

NOTE : The ring compressor will not fit on

over size pistons.

5,7,11, Cylinder Head, Cylinder and

Intake Socket

Check flatness of intake sockets.

Refer to ENGINE DIMENSION MEASUREMENT

04-04 and look for checking surface flatness.

At cylinder and / or cylinder head installation, use

aligning tool or exhaust manifold itself to ensure

sealing of intake manifold and exhaust before

tightening cylinder head nuts.

A01B1QA

1

2

3

529 0169 00

1

2

A01C02A

-

ENGINE TYPE

RING COMPRESSOR

P /N

503 420 8769 70

ENGINE TYPE

ALIGNING TOOL

P/N

503 420 8761 71

Loading...

Loading...