Section 04 ENGINE

Sub-Section 02 (454, 583 AND 670 ENGINE TYPES)

04-02-2

REMOVAL FROM VEHICLE

Disconnect or remove the following from vehicle.

– air intake silencer

– belt guard and drive belt

– drive pulley

– carburetors and throttle cable at oil injection

pump

– impulse line, oil supply line and rotary valve

shaft lubrication hoses then plug all these hoses

– ignition coils and ignition module

– temperature sensor connector, 4 circuit con-

nector, 3 circuit connector and black / yellow

wire

– drain the cooling system and disconnect hoses

from the engine. Refer to COOLING SYSTEM

04-08

– 4 screws retaining support to frame

ENGINE SUPPORT AND

MUFFLER DISASSEMBLY AND

ASSEMBLY

1,2, Manifold Screw and Engine

Support Screw

Torque the engine support screws to 48 N•m (35

lbf•ft).

Torque the manifold screws to 23 N•m (17 lbf•ft).

INSTALLATION ON VEHICLE

To install engine on vehicle, reverse removal pro-

cedure. However, pay attention to the following :

– Check tightness of engine rubber mount nuts.

Torque to 25 N•m (18 lbf•ft).

– After throttle cable installation, check carbure-

tor maximum throttle opening and oil injection

pump adjustment.

– Check pulley alignment and drive belt tension.

CAUTION : A red dot is printed on one

carburetor and on oil pump mounting

flange. Match the marked carburetor to the

side marked on the oil pump mounting flange

(magneto side). This is required because of the

different jettings.

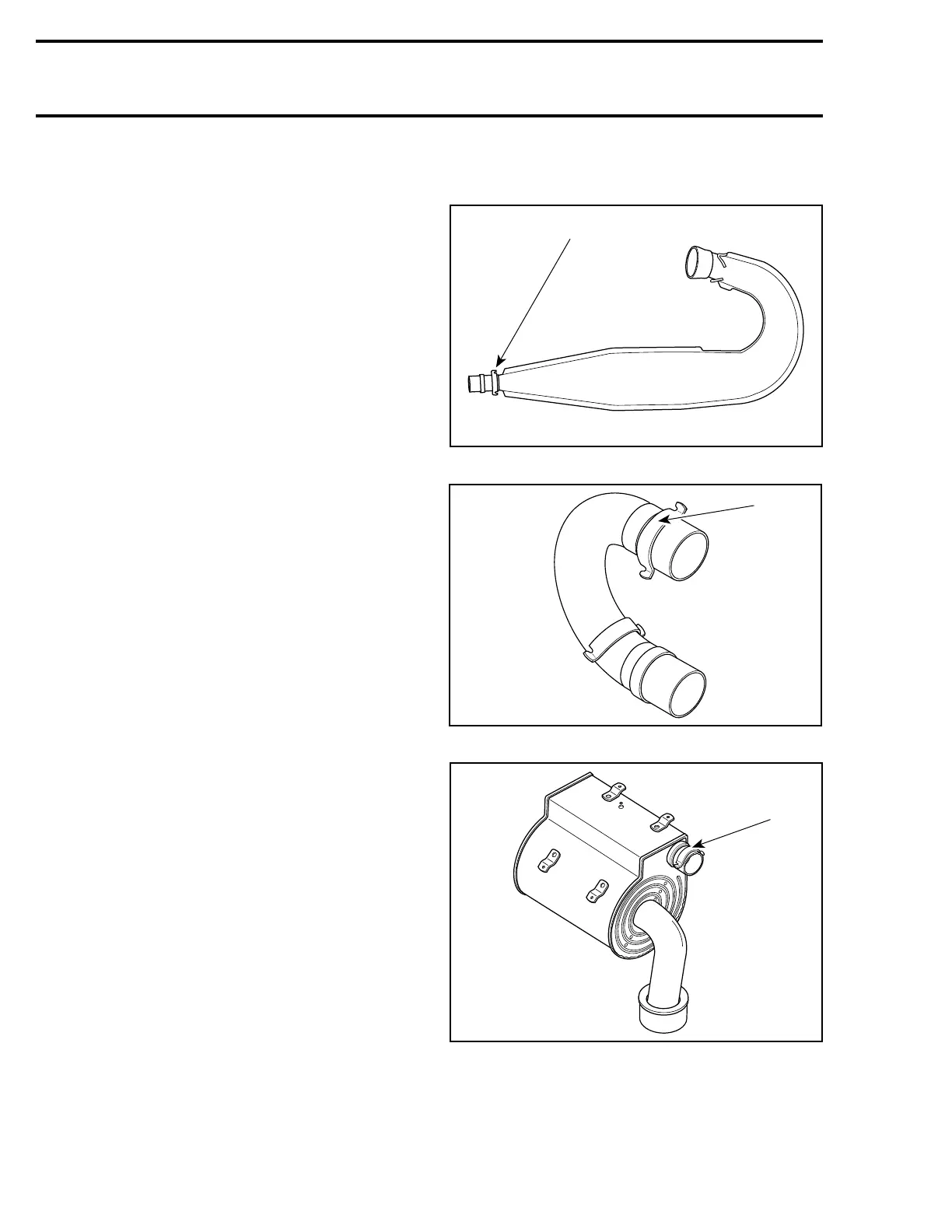

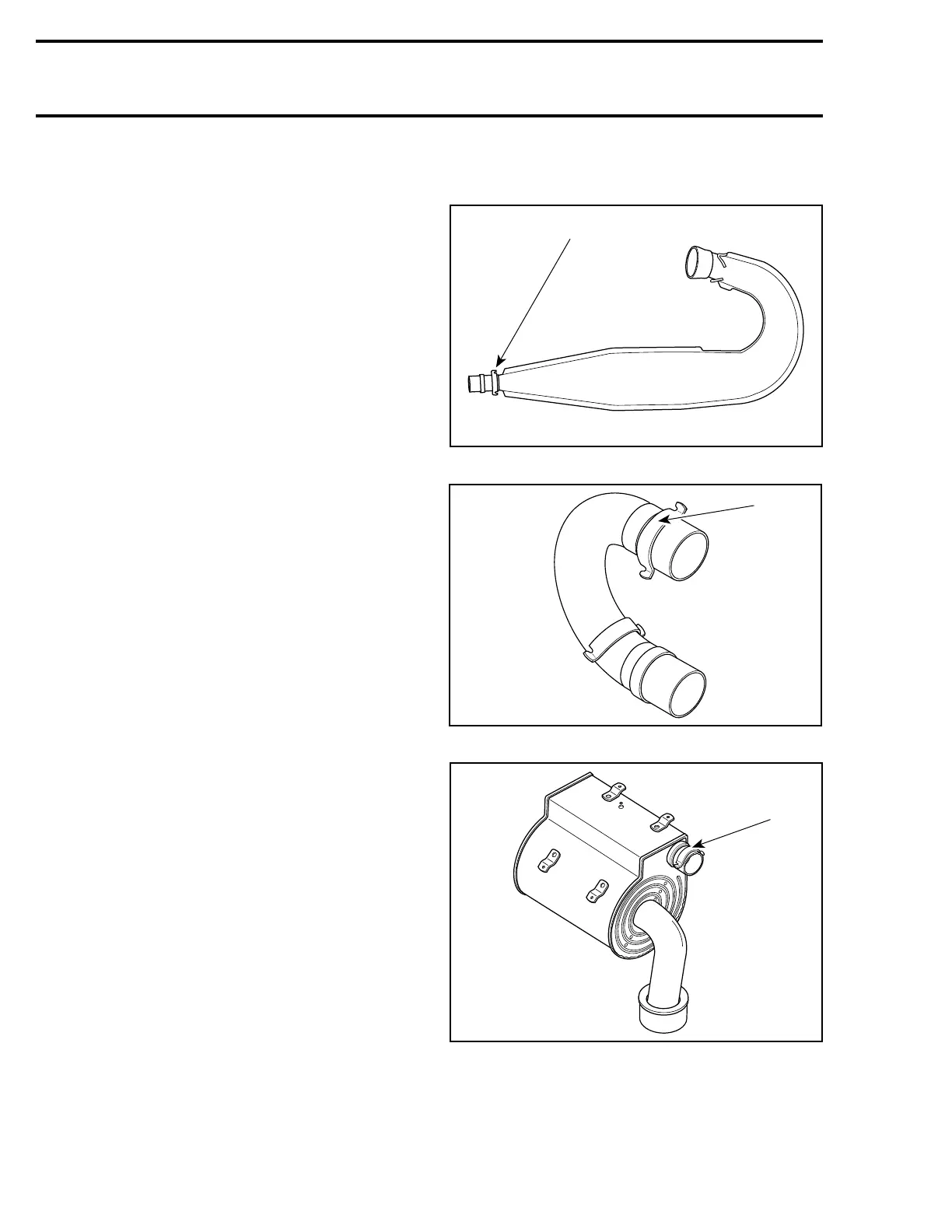

3,4,5, Tuned Pipe, Tail Pipe and Muffler

These parts are identified on welded hook.

Second number sequence of P / N is stamped on

part.

1. Example : 0392 for 514 0392 00

1. Number sequence

1. Number sequence

– Should a light exhaust leak be experienced at

any ball joints, Dow Corning sealer no. 736 RTV

(P / N 413 7092 00) can be used.

-

X

X

X

X

A06C1JA

1

X

X

X

X

A06C1KA

1

Loading...

Loading...