Section 04 ENGINE

Sub-Section 02 (454, 583 AND 670 ENGINE TYPES)

04-02-7

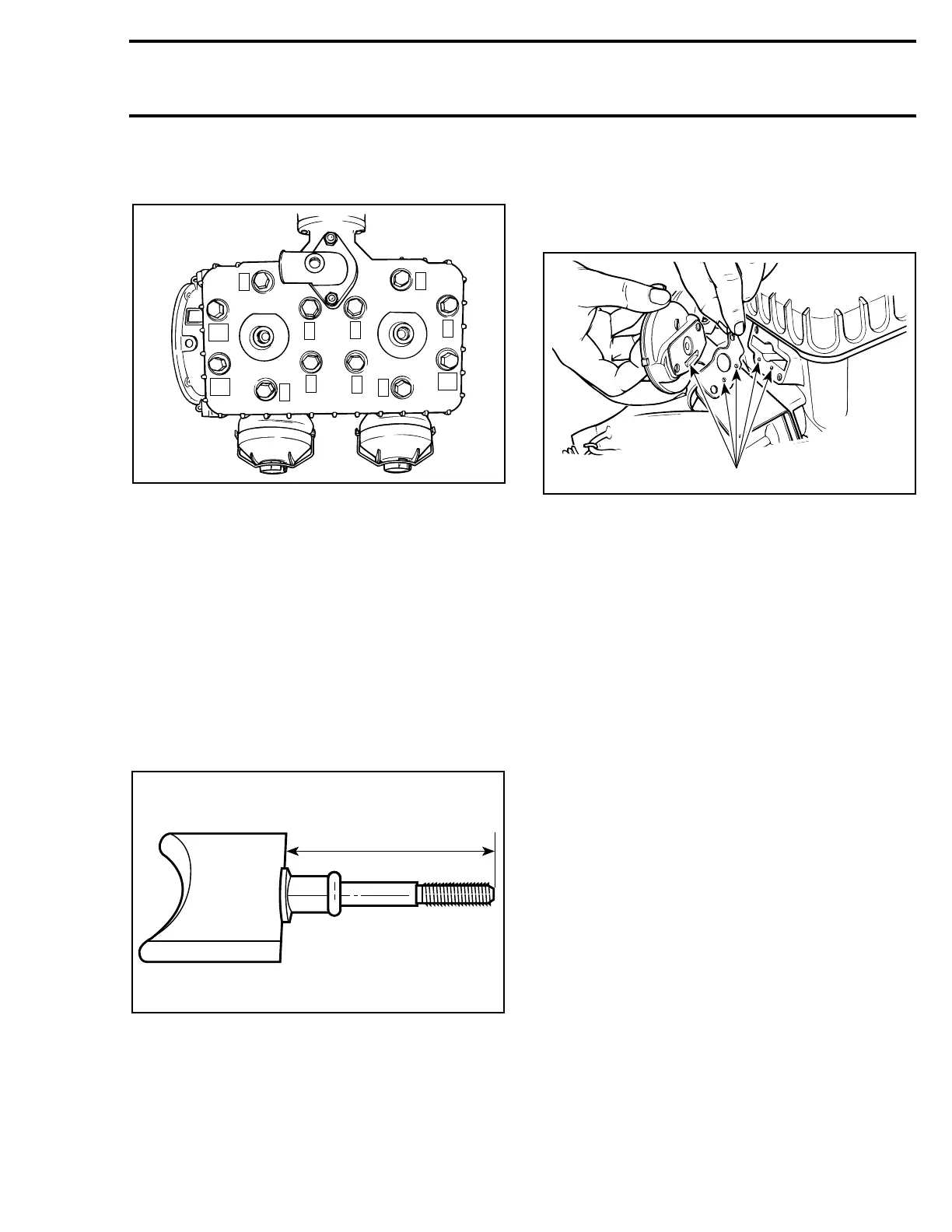

Torque cylinder head screws following illustrated

sequence. Longer screws go on intake side.

1, Nut

Torque nuts to 10 N•m (90 lbf•in).

RAVE SYSTEM

15,16,17,18,19,20, Valve Rod,

Threadlocker, O-ring, Washer, Distance

Nut and Exhaust Valve

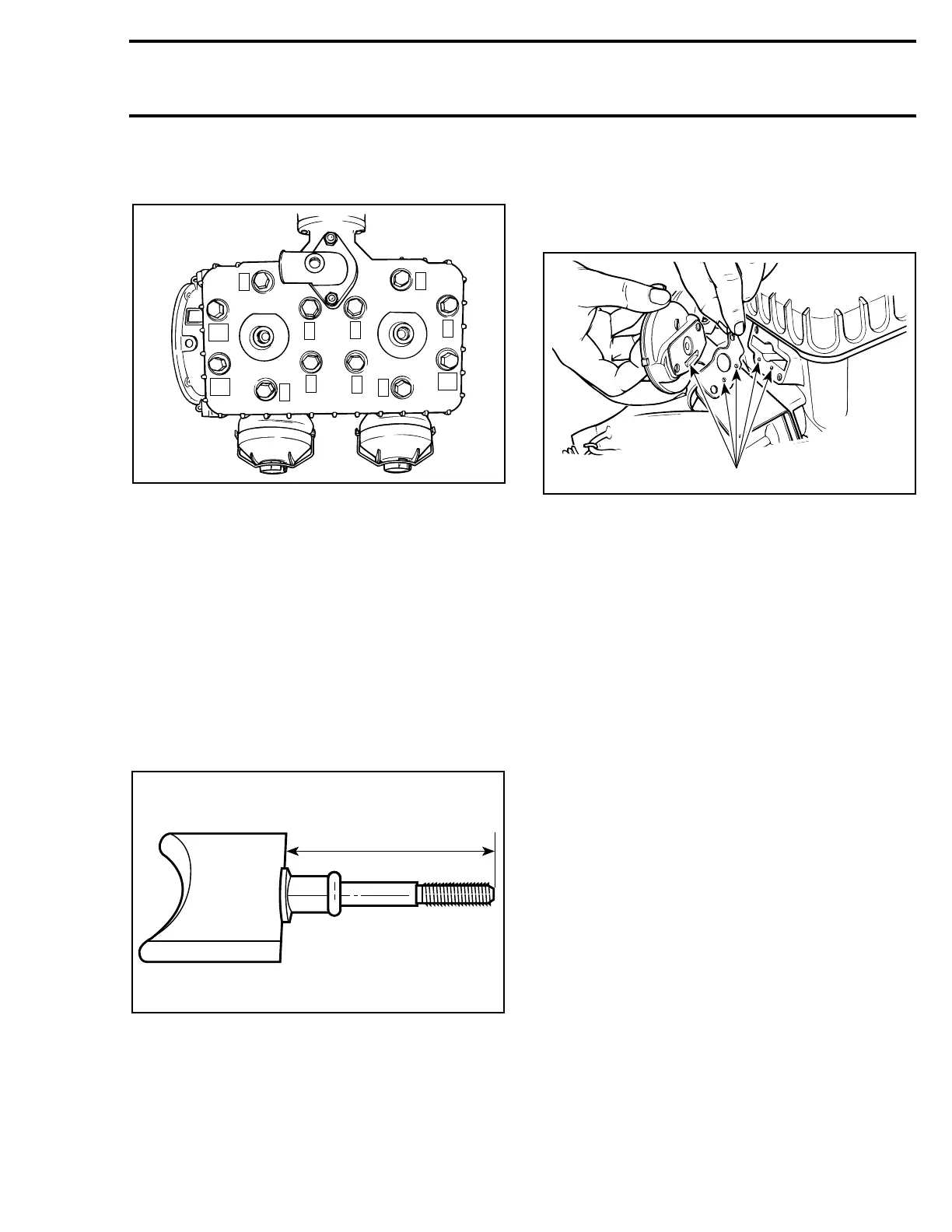

Fully screw distance nut, with its notch first, on

valve rod longer threaded portion. Install washer

and apply high temperature threadlocker (P / N

420 8997 88) on threads. Screw valve rod into ex-

haust valve until following distance is respected.

A. 583 engine type = 63

-1

mm (2.480

-.039

in)

Back off distance nut to jam the assembly. Install

O-ring. Install exhaust valve assembly in cylinder

with its cut-away downward (see illustration at re-

moval).

11,12,13,14, Cylindrical Screw, Lock

Washer, Valve Rod Housing and Gasket

Install gasket and valve rod housing with their pas-

sages toward bottom.

1. Passages

Torque cylindrical screws to 10 N•m (90 lbf•in).

Check free sliding action of valve assembly.

7,8,9,10, Valve Piston, Clamp 50 mm,

Bellows and Clamp 21 mm

Install bellows over valve rod housing groove and

secure with a clamp.

Screw by hand valve piston on valve rod until it

bottoms.

Secure bellows to valve piston with a clamp.

3,4,5,6, Spring Clip, Adjustment Screw

Cover and Spring

Install spring, cover and spring clip. Turn adjust-

ment screw by hand until it bottoms.

A24C0JA

5

11

1

12

6

4

3

2

7

9

8

10

A24C0SA

A

Loading...

Loading...