Section 04 ENGINE

Sub-Section 02 (454, 583 AND 670 ENGINE TYPES)

04-02-9

NOTE : Engine must be removed from

chassis to perform the following proce-

dures.

CLEANING

Discard all oil seals, gaskets, O-rings and sealing

rings.

Clean all metal components in a non-ferrous met-

al cleaner. Use gasket remover (P / N 413 7085

00) accordingly.

Remove all trace of Loctite from crankshaft taper.

Remove old paste gasket from crankcase mating

surfaces with Bombardier gasket remover (P / N

413 7085 00).

CAUTION : Never use a sharp object to

scrape away old sealant as score marks

incurred are detrimental to crankcase sealing.

DISASSEMBLY

General

To remove drive pulley, refer to DRIVE PULLEY

05-02.

To remove magneto, refer to CDI MAGNETO 04-

05.

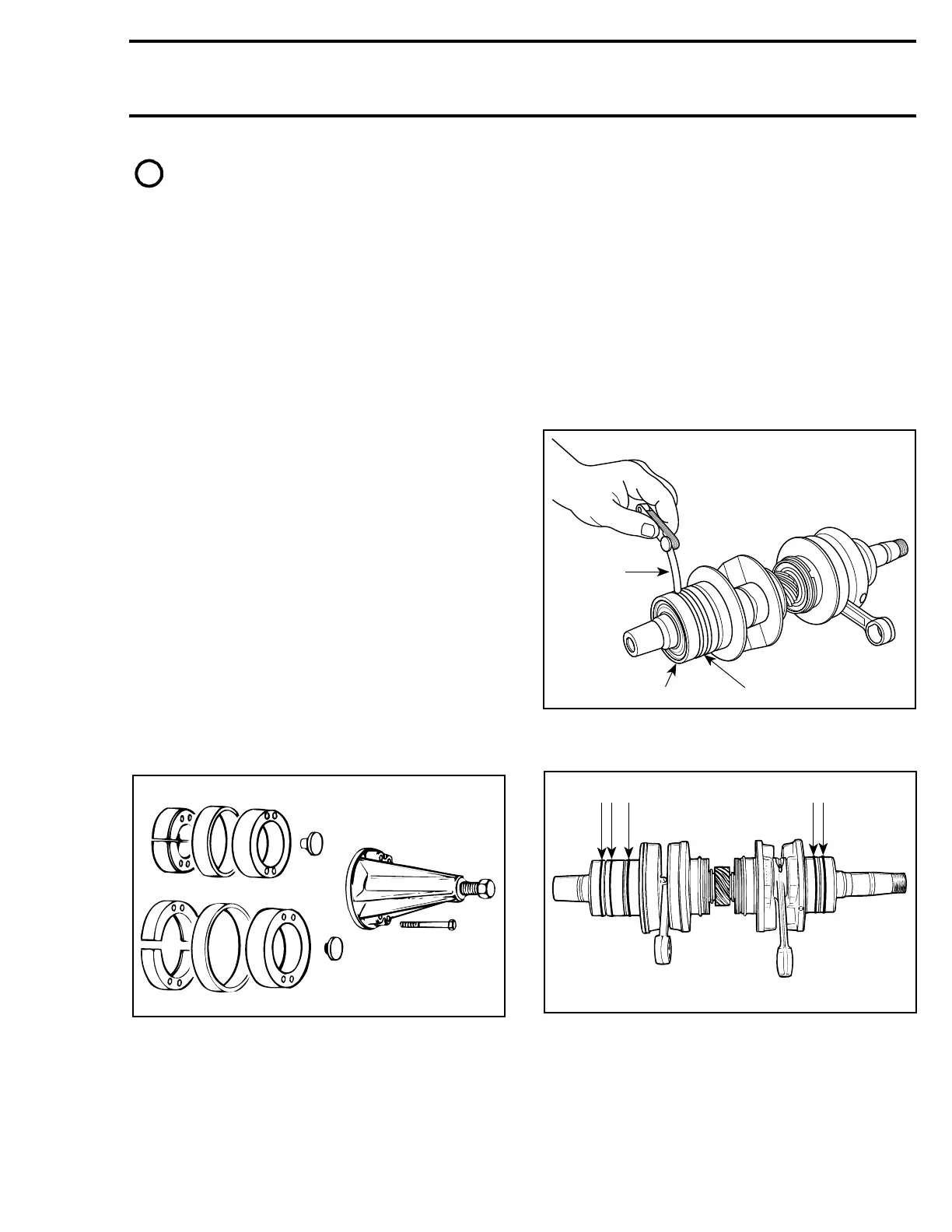

2,4,6,9, Crankshaft Bearing

To remove bearings from crankshaft, use a pro-

tective cap and special puller, as illustrated.

1. PTO side

2. MAG side

INSPECTION

See ENGINE DIMENSIONS MEASUREMENT 04-

04.

ASSEMBLY

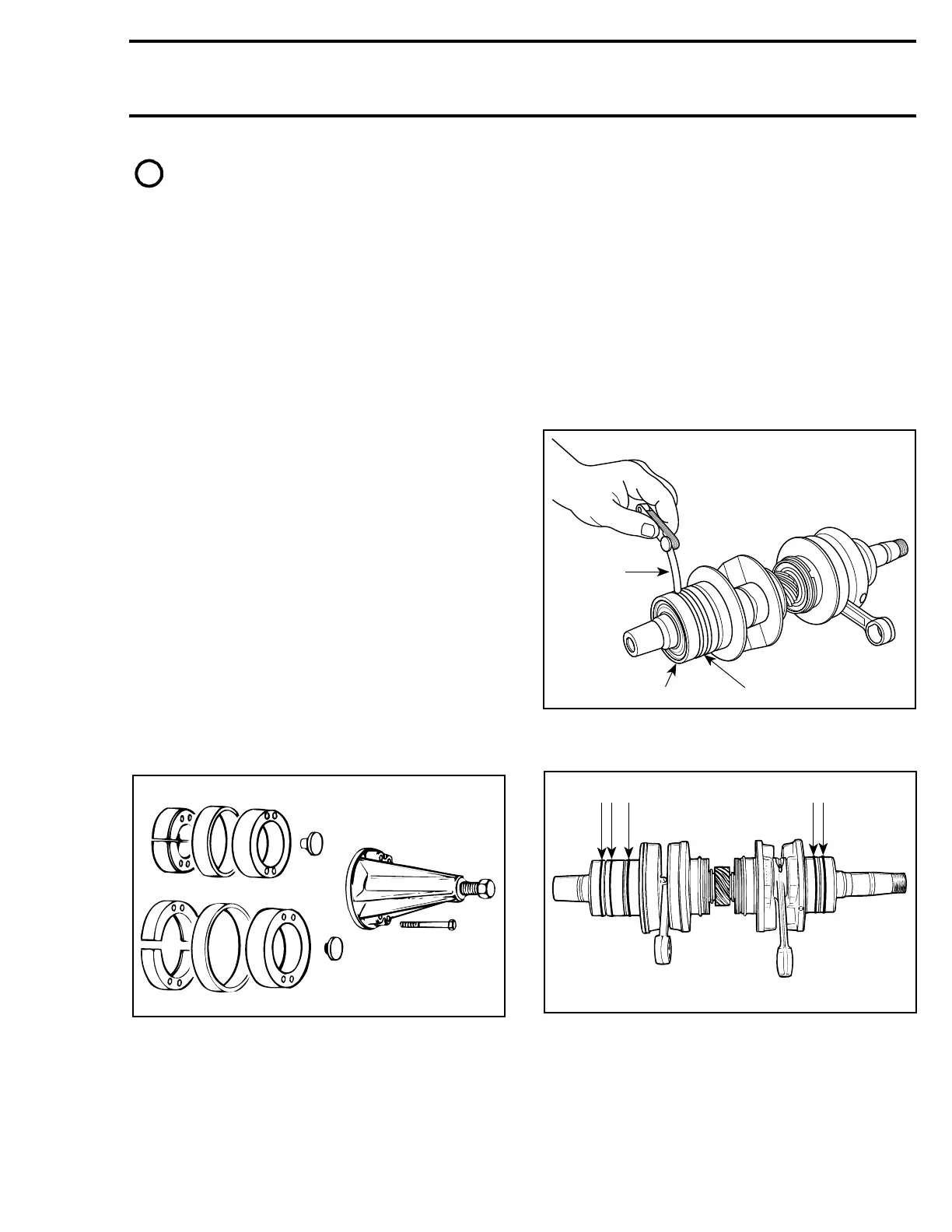

2,4,5,6,9, Crankshaft Bearing and

Labyrinth Sleeve

Smear anti-seize lubricant (P / N 413 7010 00) on

part of crankshaft where bearing fits.

Prior to installation, place bearings into an oil con-

tainer filled with oil previously heated to 75°C

(167°F). This will expand bearing and ease instal-

lation. Install bearings and labyrinth sleeve with

groove as per the following illustration. Keep a 0.3

mm (.012 in) gap between outer bearing and lab-

yrinth sleeve.

1. Labyrinth sleeve

2. Outer bearing

A. 0.3 mm (.012 in)

ALL ENGINES EXCEPT 454 AND 670

-

Loading...

Loading...