WWW.SMITTYBILT.COM

Installation Instructions

Scout Trailer Kit

Part#87400/87400-01

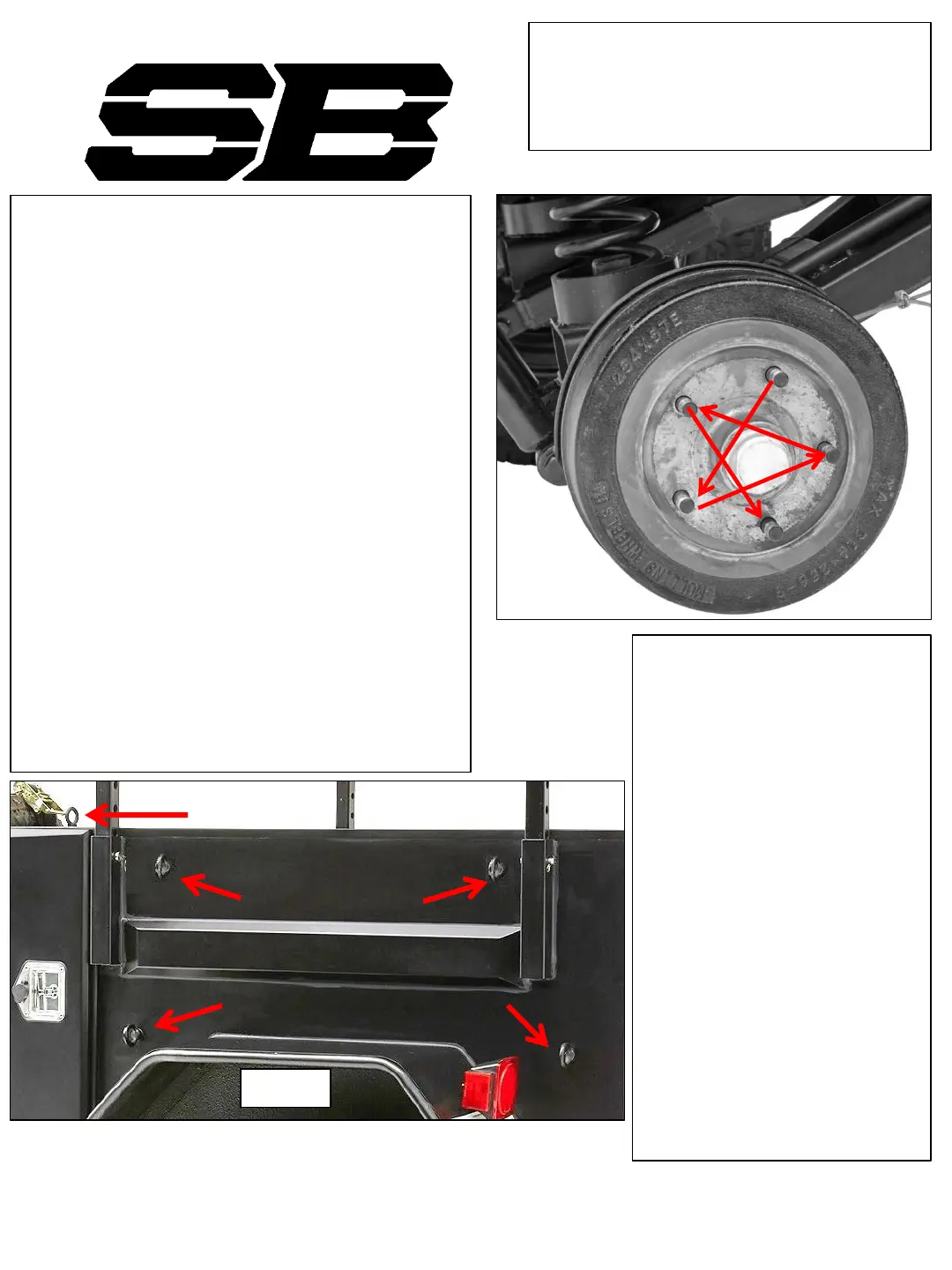

20. Install tires and wheels on to axles. Make sure

center caps are inside of the wheels before

installing. (only if wheels use push thru cap)

you may want to apply anti-seize to the wheel

mounting surface to help prevent corrosion

and will make the wheel easier to remove

when rotating tires, you may also apply a small

amount of anti-seize to the lug studs. The

trailer kit comes with 60° conical seat lug nuts,

make sure your wheels have a compatible

seat. Make sure lug nuts have at least ½” of

thread engagement. Tighten the lug nuts in a

star pattern. Make sure to properly torque the

wheels. Then re-torque after the first 25 miles

and then each 50 miles till they hold their

torque. Always check wheel manufactures

torque recommendations/specifications. Do

not exceed 95 ft. lb. Lower torque ratings

when using anti-seize on the threads,

generally about 25% less torque is required

when using anti-seize. Generally ½” lug nuts

need to be torqued to 85-95 ft. lb. Fig 14.

Fig 14

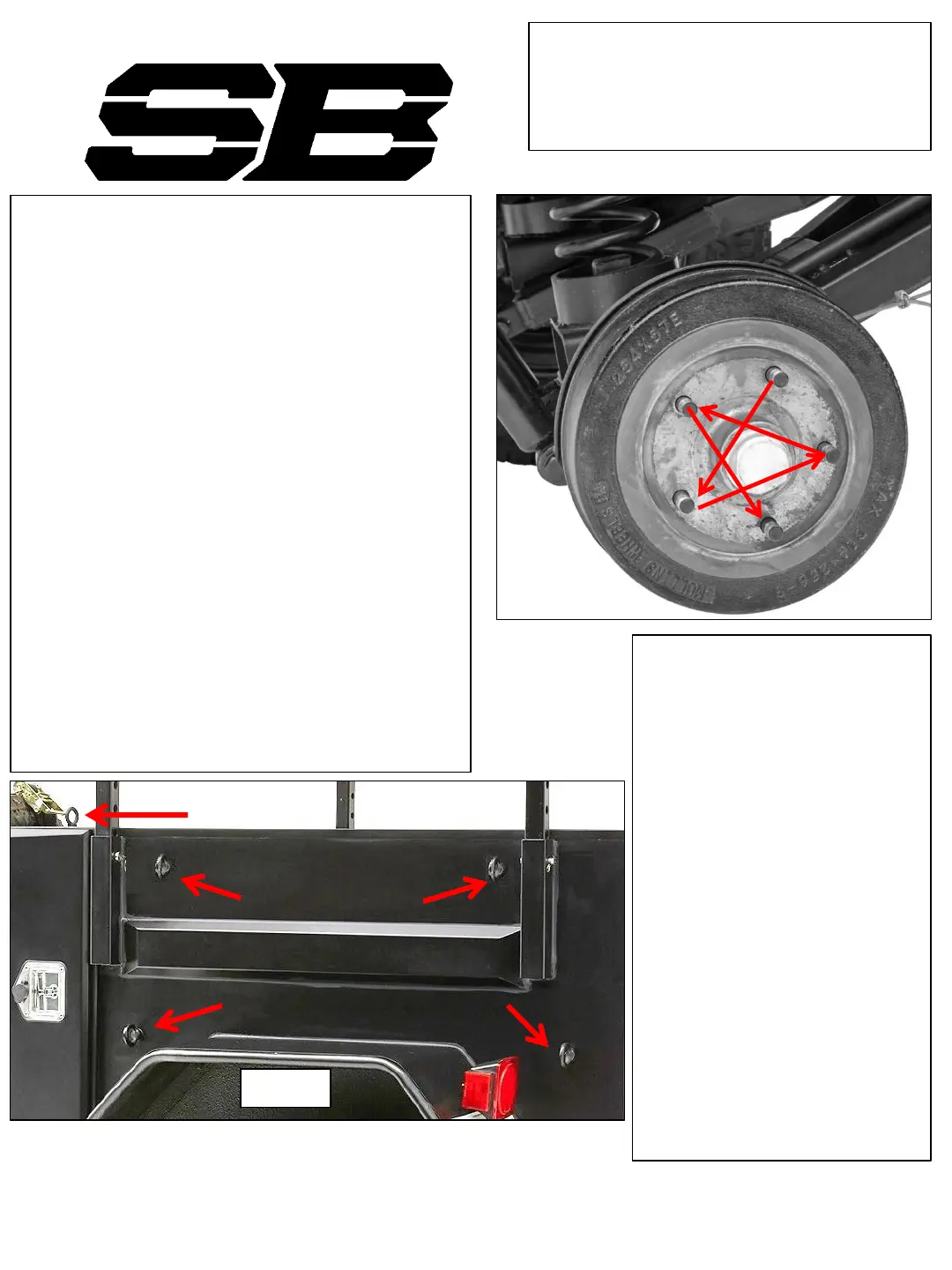

21. Install all eyebolts. They

may be installed in any

clocking position but we

have found the best is a

vertical orientation. Seal all

eyebolts with black silicon

sealant to prevent ingress

of dust/water. Each eyebolt

assembly consists of a male

and female eyelet, one side

will be on the outside of

the trailer and the other

will be on the inside. On

the roof of the trailer in the

front near the spare tire

you will use a male eyebolt

only. It will thread into the

threaded hole . This

eyebolt can be used to tie

down the spare tire. Fig 15.

Fig 15

20

Loading...

Loading...