Technical manual Sylax DN 25-350 mm

Connecting flanges

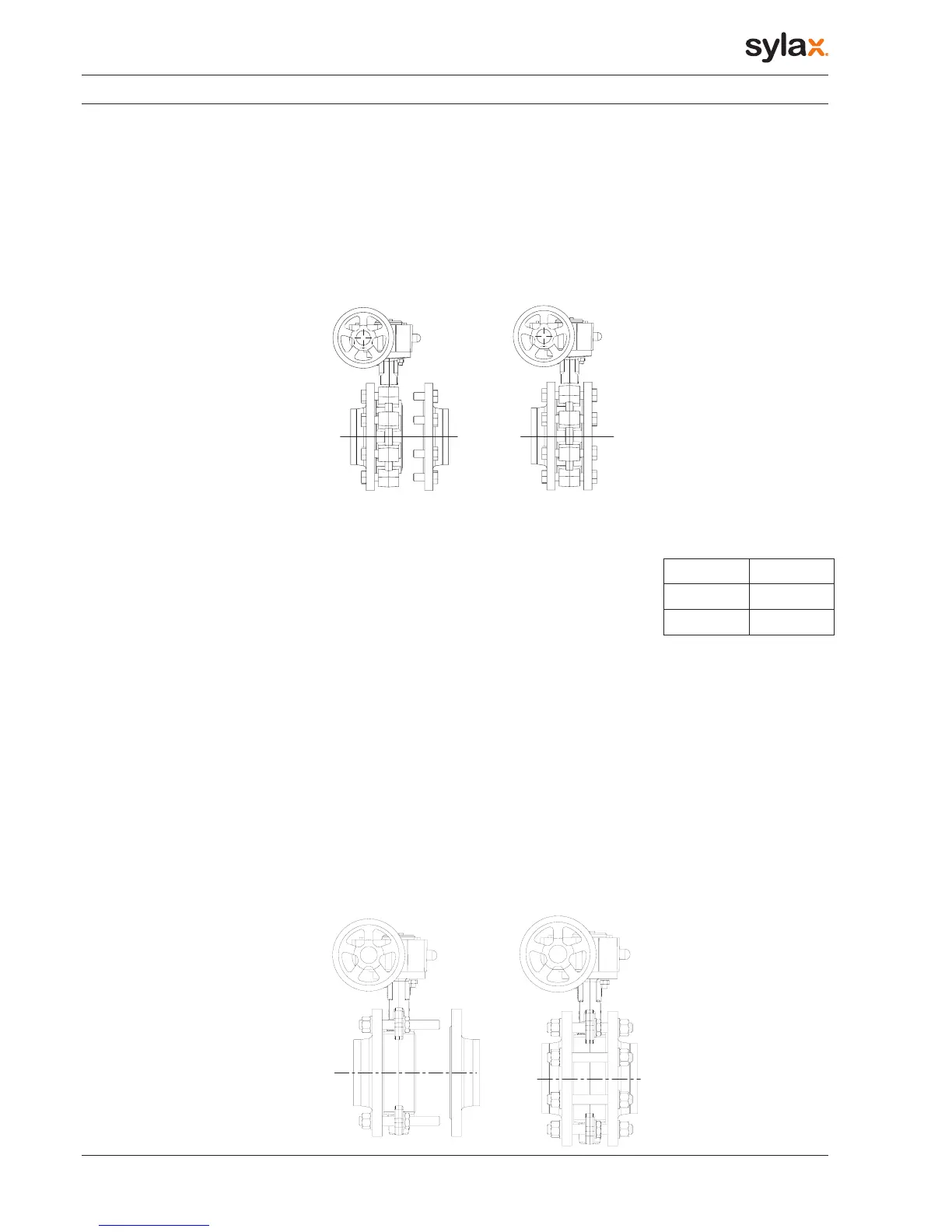

• End of line mounting and downstream removing

The end of line mounting and the downstream removing, at ambient temperature, of the Sylax 25-350 mm butterfly valve is

limited to the pressure mentioned on page 11 according to the PED directive 2014/68/UE.

These mountings are only possible on tapped lugs and lugs with unthreaded holes.

Downstream

removing

End of line

mounting

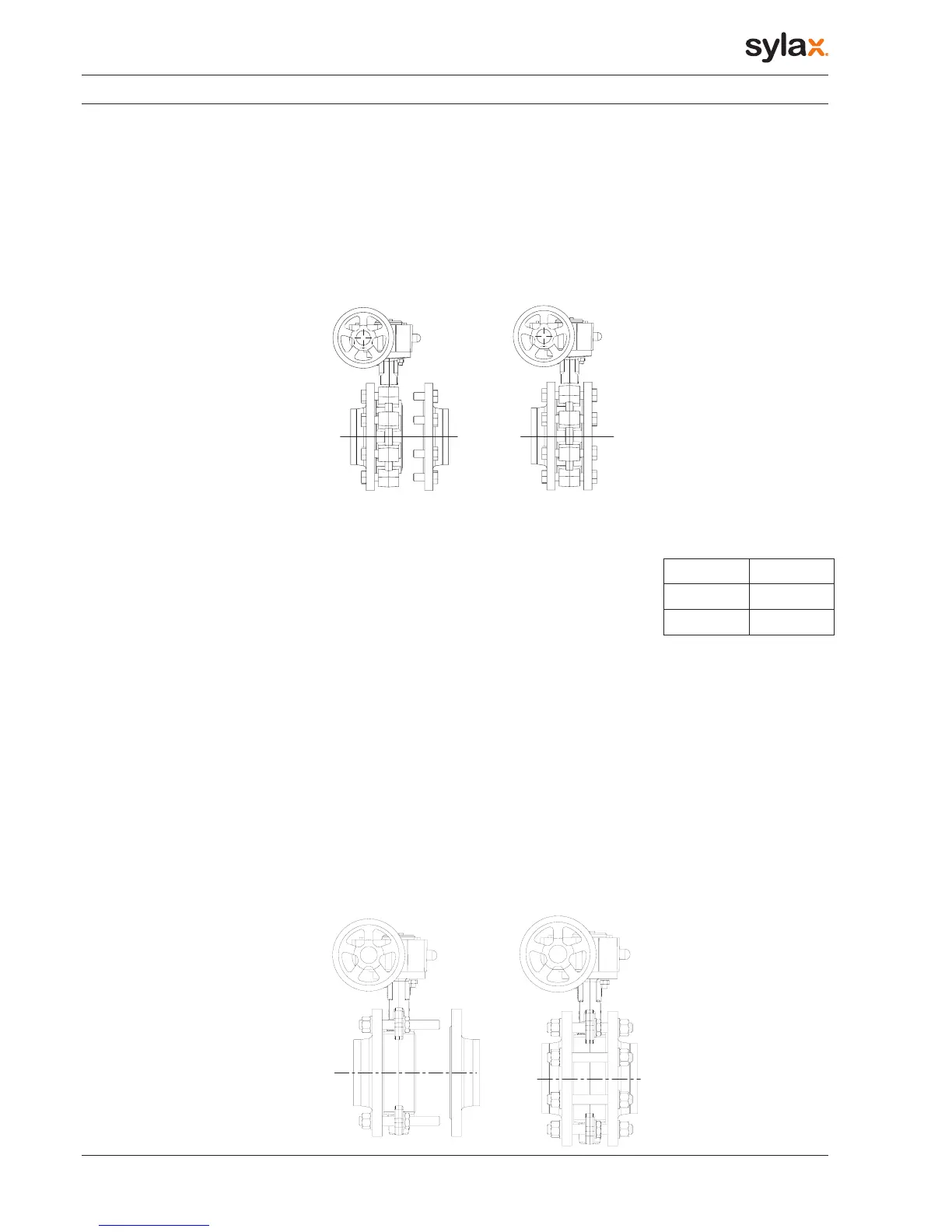

For wafer type bodies with 4 centering lugs, the end of line mounting can be done

in the following conditions :

- ambient temperature

- For water or non dangerous liquids (L2)

- For butterfly valves PFA 16 bar between flanges

- For butterfly valves with ductile iron body

- For butterfly valves with liners in EPDM or high content nitrile

- Within a short period (such as maintenance, ...), 15 days maximum

- In pressure conditions (PFA or PS) such as : see table

Use nuts with reduced face-to-face dimensions between the flange to be dismounted and the centering lugs.

Use washers, wide ones if needed, in order to mount the nuts on the lugs.

The mounting and the removing must be done successively and in opposite way on each nut.

For the mounting, apply a reasonable torque on the nuts, in order not to damage the lugs, until metal-metal contact between

flange and body.

For flanges with 8 rods, only 4 are used to maintain the valve in downstream removing ; the 8 rods must be re-mounted for a

normal use between flanges .

In case of unexpected downstream removing, integrate and screw successively and in opposite way, between the lugs and the

flange to be removed, the 4 nuts which hold the butterfly valve.

Downstream

removing

Mounting

between flanges

8 uksylax25_350 - Updated 20/09/2016

DN

PFA or PS

(bar)

32 to 150 10

200 to 300 8

Loading...

Loading...