Soosan

H

draulic Breaker

Soosan Heav

Industries Co.

Ltd

■ Replacement & Breakage of Rod

- Rod is deformed of burrs produced in a long term use.

- If the rod tip is worn out, rod is liable to slip. Grind the rod tip to sharpen the edge.

- If the rod tip is sharpened many times, the hardened surface layer will disappear and the rod will be

worn out rapidly. In this case, replace with a new rod.

- If the gap between rod and front cover is large, the piston fail to fit in rod to cause damage to the piston

or the rod.

● Replacement

① Put the breaker horizontally on the timber.

② Remove the spring pin(SB43 below) or rubber plug(SB45 above) using a

pin bar.

③ Set round bar on the opposite side, and push the stop pin with a hammer.

④ Remove the rod pin. In removing the rod pin, be careful falling of rod and

rod pin.

⑤ Wind rope or nylon sling around the rod and remove from the main body.

⑥ Before installing a new rod, check wear, breakage and score.

Remove burrs and swelling from the disassembled rod pin with a grinder.

Excessively deformed rod pin will make replacement of rod difficult. Rod

pin is required to be checked every 100 to 150 hours of operation

⑦ Grease sufficiently to inserting part of front head.

Rod pin

Rod

Stop pin

1

2

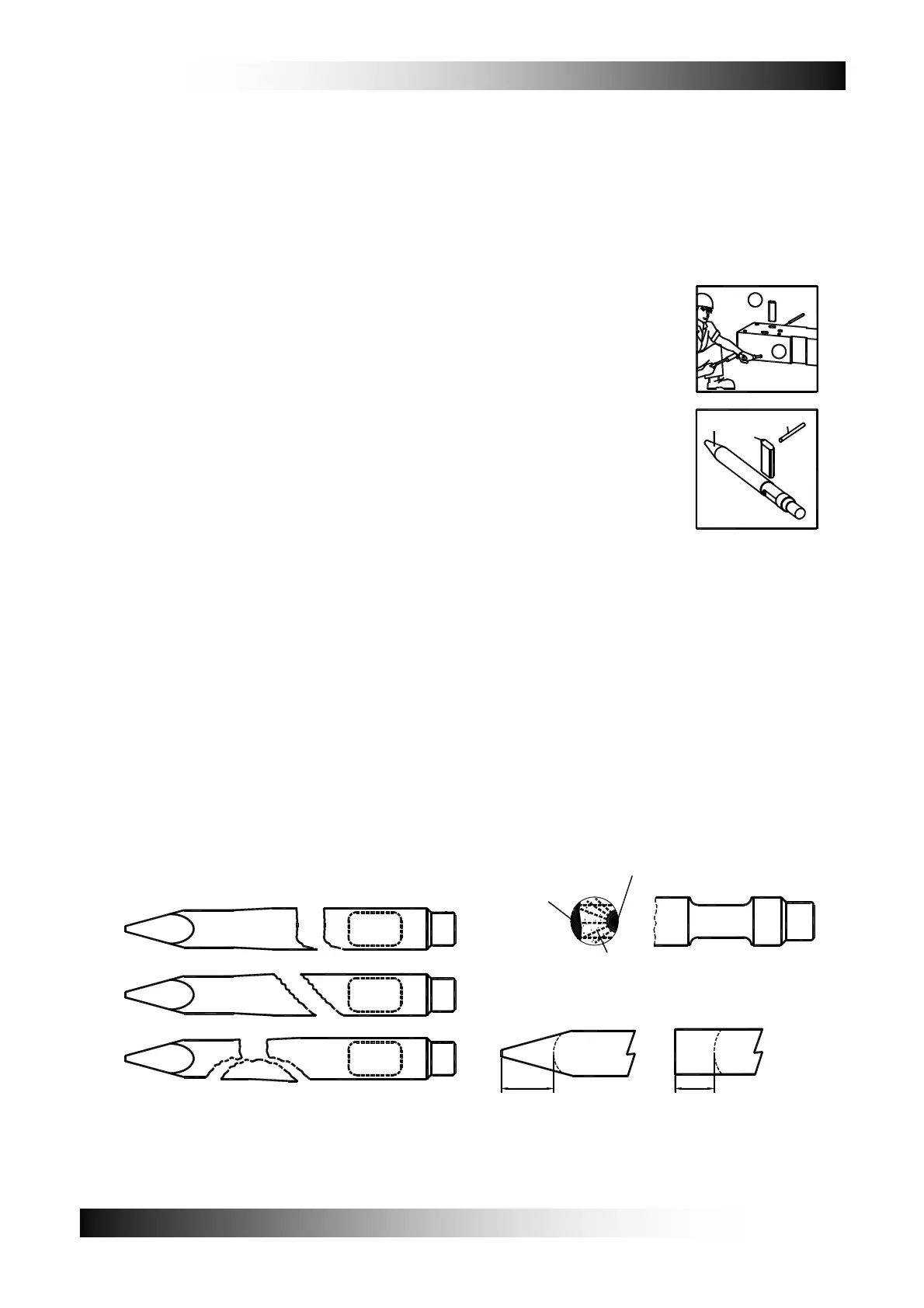

● Breakage of Rod

The service life of the rods depends on the manner of handling them. The rod can sufficiently

withstand the vertically acting load, but is weak to the perpendicularly acting load. Especially, the rod

is affected by the negative conditions such as force by craning operation, tilted blowing, wrenching

and idle strokes etc.

There are several ways of breakage of the rod. Each cause of the breakage can be inferred by

observing the breakage section. Further, the breakage case which is not caused by low quality

materials or insufficient heat-treatment but by wrong way of handling which the manufacturer is not

responsible for the breakage.

The breakage section has the origin on the outer surface, the narrow area of fatigue breakage and the

wide area of rough grey area, and final breakage part has the share-lip form. Such as undulation on

the breakage section and its inclination to the right and left witness that the breakage is caused by

excessive force which excessive force which exceeds the toughness of the rod. Such the breakage is

supposed to occur owing to careless handling of the rod. To avoid such the breakage more

carefulness and attention is required in handling the breaker.

of the rod. Warranty claims rejected.

Typical fractures caused by excessive bending

buried in the burden. Warranty claims rejected.

Typical fractures caused by levering tool while

Stress concentration point

(Starting point)

at 90° to the rod pin plate.

Sharp lip

Rough Grey Area

and wedge,universal type rods worn back more than

Flat type rod worn more than 45mm or moil type

75mm of working end classed as reasionable life.

Warranty claims rejected.

75

45

Loading...

Loading...