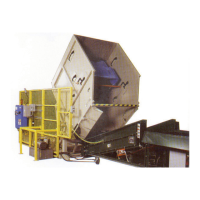

What to do if the tilt mechanism does not lower on my Southworth APCU Industrial Equipment?

- AAaron ChenAug 20, 2025

If the tilt mechanism doesn't lower, the issue might be with the control valve. Ensure the “down” side of the valve is energized and fully open. Use a voltmeter to check the solenoid on the “down” side of the valve. Inspect the wiring to the control valve for any problems. The valve must be clean and free to operate, so release the pressure from the system and clean the valve.