27

28

45

42

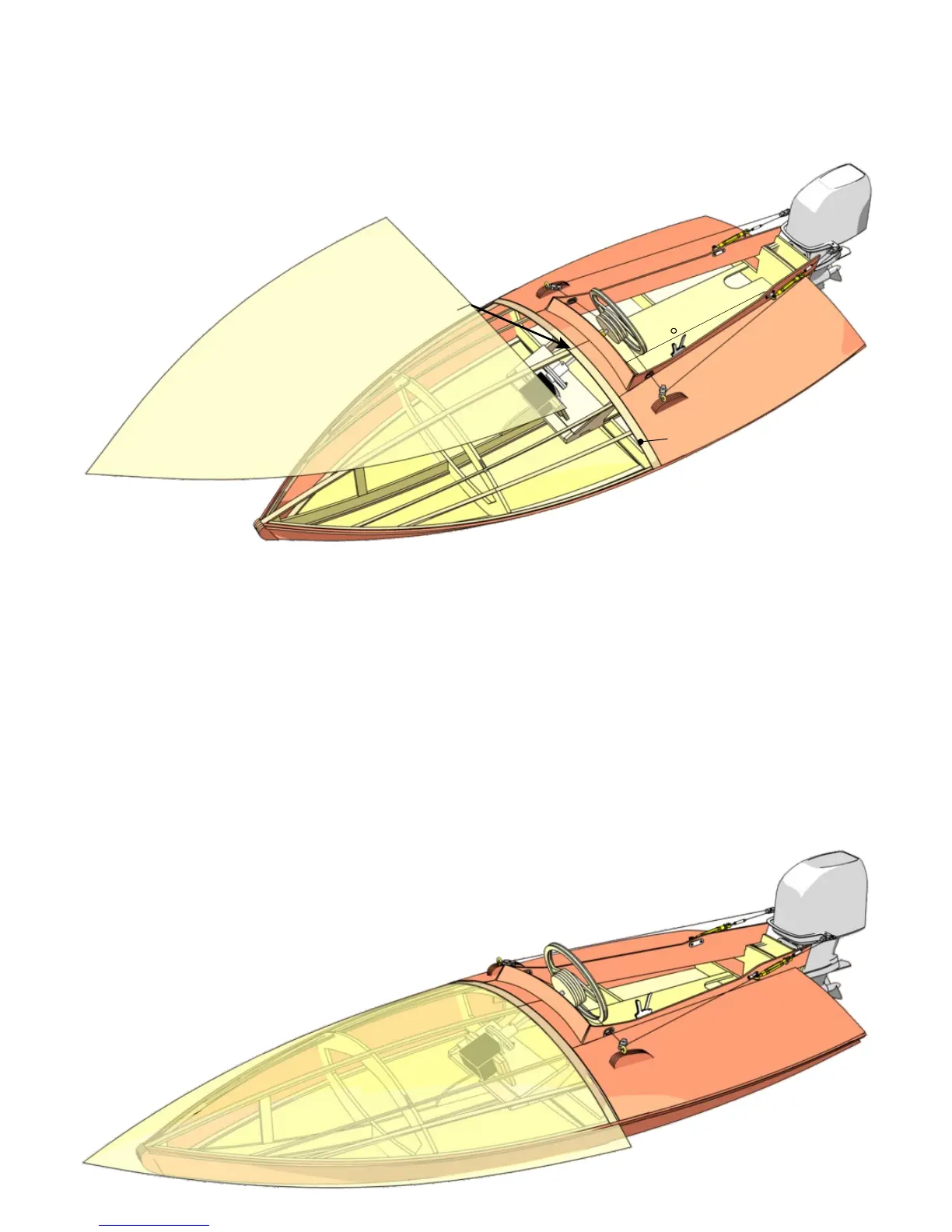

Position the fabric accurately, then iron it down onto part 45 using a film iron set to a temperature of 80 - 90°C.

Pull the fabric tight towards the bow, and iron down a small area at that point. Now gently pull the fabric over

the edge on both sides, working step by step so that it becomes taut; iron down the edges as you go. The

fabric can now be heated using the film iron or a heat gun set to 110 - 150°C, so that it shrinks and becomes

tight and smooth. Keep the heat away from the ironed-down edges when shrinking the fabric, otherwise the

heat could soften the adhesive.

The fabric shrinks as follows: 1% at 110°C

2% at 120°C

3% at 130°C

4% at 140°C

5% at 150°C

At 180°C it is also possible to stretch the fabric round curves.

The melting point of the fabric is 250°C.

Cut off the excess fabric along the edges using a sharp blade.

Place the two kneeling boards 42 in the cockpit, and screw them to parts 24.

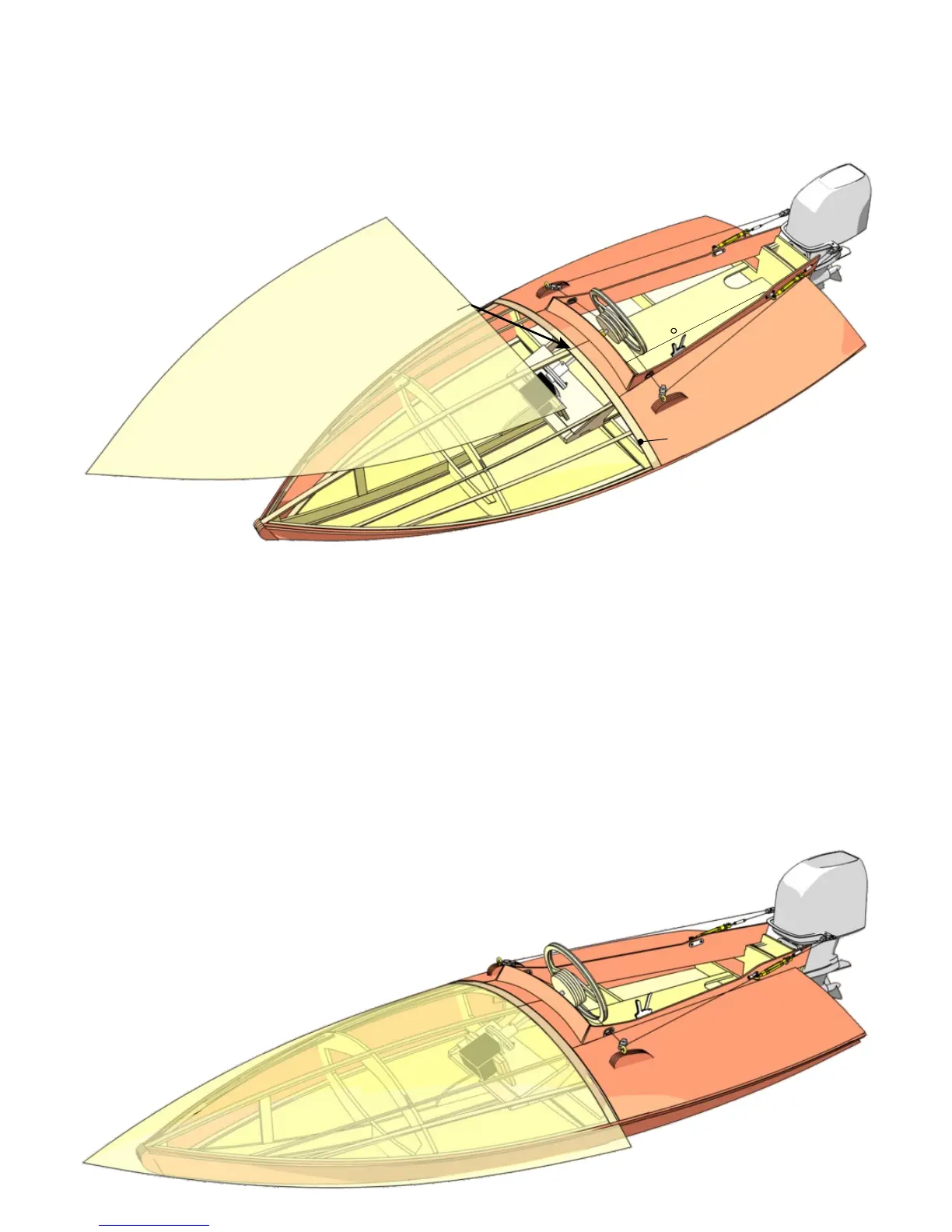

Glue the fabric support 45 on the stringers.

Peel away the silicone backing paper from the underside of the fabric, and lay the adhesive-coated face

on the hull. The fabric is cut to a slightly rounded shape, so that it naturally takes up the curvature of the

deck. The centre of the fabric has a small slit which should coincide with the centre of the deck (see

arrow).

Loading...

Loading...