22 ► MB556 User Manual

STANLEY breakers are available with several dierent

types of tool bits. The most common are the moil, chisel

and the blunt. Each of these working steels has its own

purpose as described below:

To obtain the maximum production from the breaker, it

is important to select the proper working steel. Consult

your STANLEY representative for assistance in select-

ing the proper working steel for your application.

MOIL

This is by far the most popular

working steel. It is a general

purpose point used to break

anything from concrete to

hard rock. Its pencil-type

point is used to fracture the

material. The tool is best where

penetration speed is important.

CHISEL

This style of point is used

generally used for trench work,

where a controlled break is

required, and for rock breaking

on materials with a denite line

of cleavage. A chisel bit also

works well in softer concretes

where a moil might penetrate

quickly, but not cause a fracture

line.

BLUNT

This at type of point is used to

break softer material such as

coal or shale. A moil or chisel

will tend to punch holes in this

type of material, where a at

blunt will shatter the material.

It is also useful when breaking

irregularly shaped material

where its broad tip makes it

easier to position.

The other parts of the broken surface are brittle.

This is the only kind of tool bit failure that is always

covered under warranty.

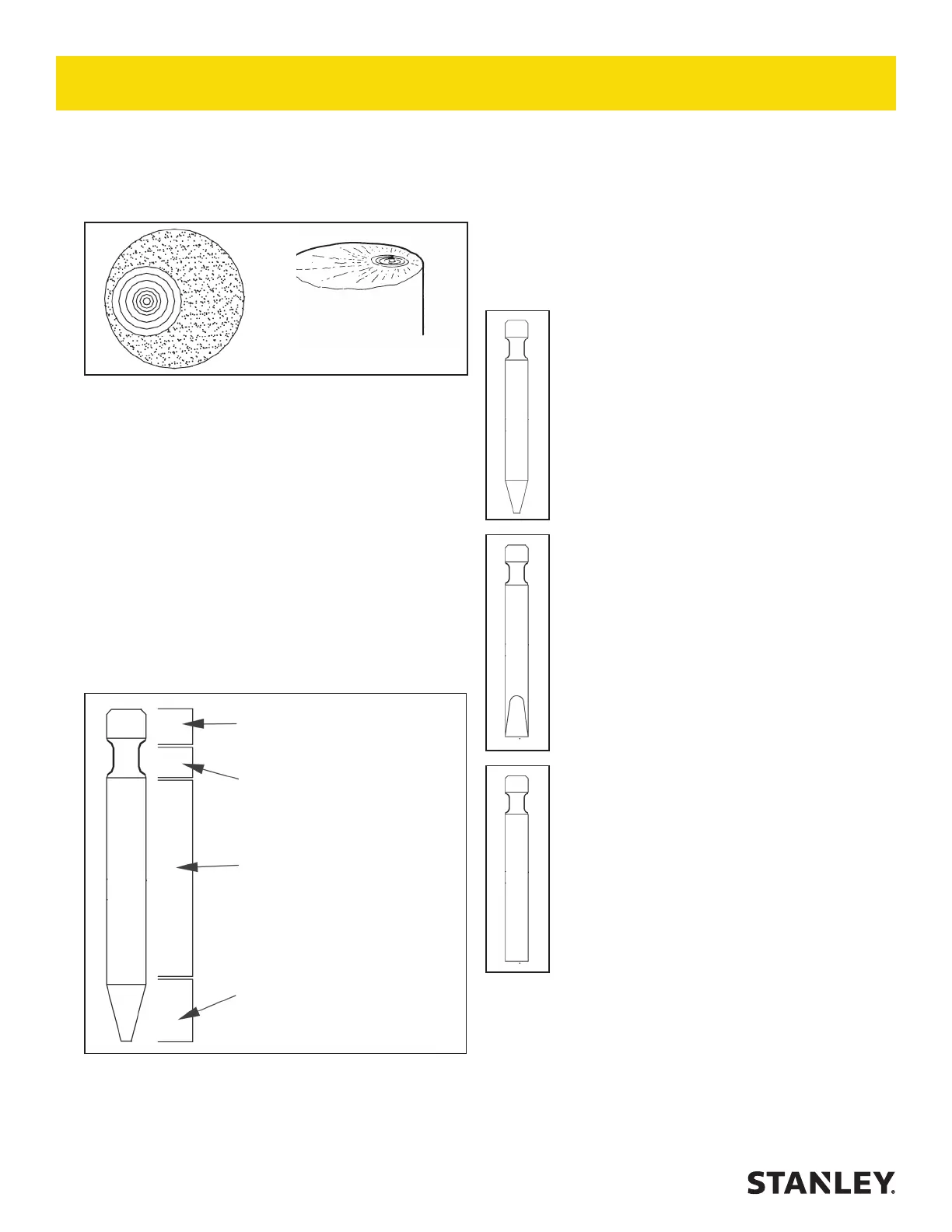

Figure 25. Internal Material Flaw

As a rule, working steel failures can be diagnosed by

looking at the break itself, and at the place on the steel

where the break occurred. Discoloration, like “rainbow”

eects or blue bands, is the result of extreme heat.

Look for surface cracks, galling, or gouge marks. Breaks

that start as surface damage have a “sea shell” pattern,

with the damaged spot at the center. A large “sea shell”

indicates a slow growing break. A small one indicates

one compounded by side stress.

Stress failures start small, and spread into the center

of the steel. In a stress failure, the coarser the grain,

the greater the stress was, and the more rapid was the

failure.

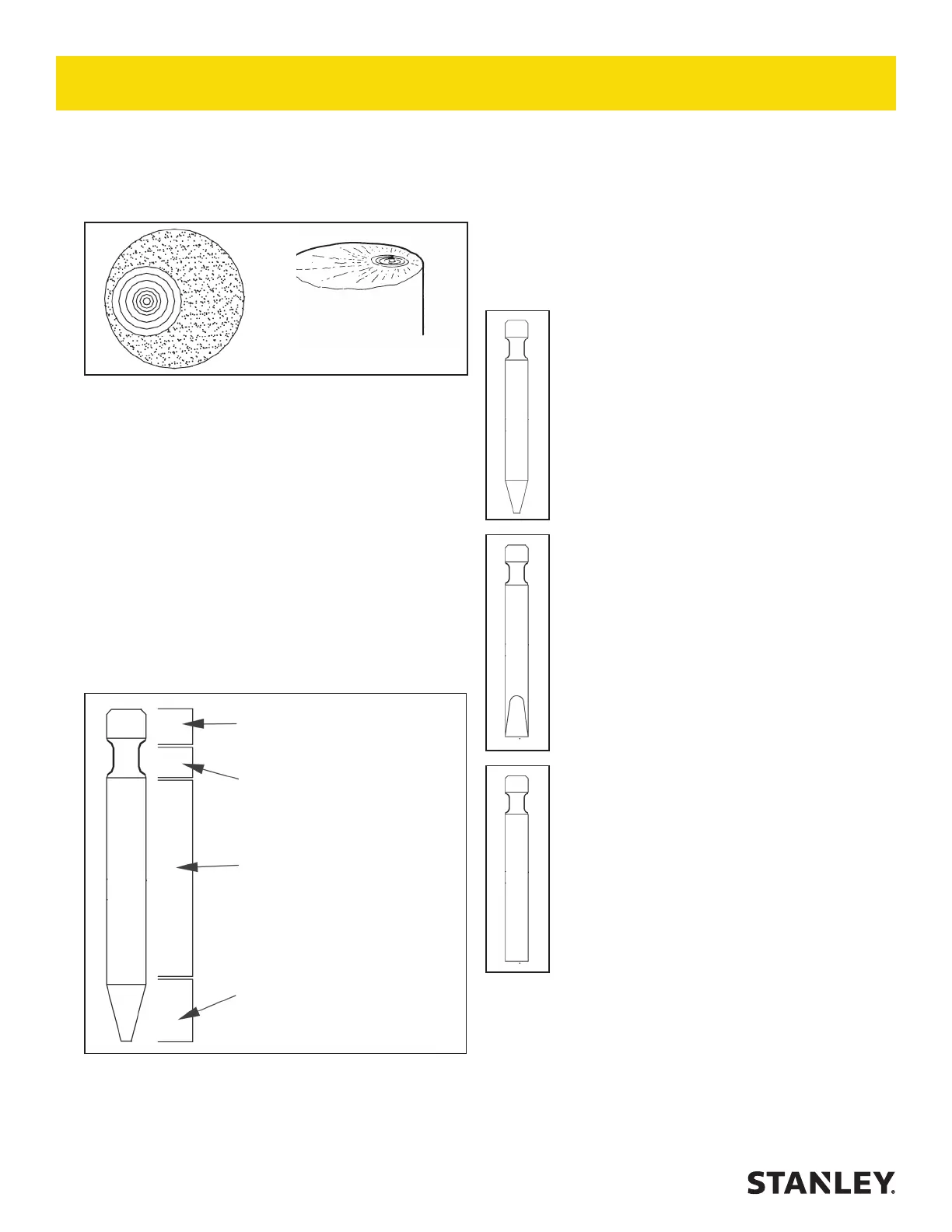

• Failures in this area are usually the result

of blank ring, worn bushing(s), worn re-

tainer pin(s) or the lack of lubrication.

• Failures in this area are usually the result

of worn retainer pin(s) or blank ring.

• Failures in this area are usually the result

of prying, metal-to-metal contact or corro-

sion. Prying failures often exhibit a shell-

like formation near the edge of the steel

diameter where the break began, and a

“tail” opposite that where the remaining

steel bent and tore.

• Failures in this area are usually the result

of heat build-up, mushrooming, or improp-

er contact with the work.

Figure 26. Diagram of Tool Bit Failures

PROPER USE & CARE OF TOOL BITS

Loading...

Loading...