OPERATING THE DEVICE

MAINTENANCE

NOTE: All gaskets must be renewed after each assembly. Make sure the device and connected

accessories are depressurized before carrying out any work on the device.

If over time, the pump starts up after a slight removal of water, approximately 0.5L, the preliminary lling

pressure in the boiler must be re-established.

1. Disconnect the mains plug

2. Open the pressure line (turn on the water spigot or nozzle), allow water to completely run off

3. Unscrew the plastic buttery valve on the front side of the boiler; the air-control valve is located

behind it.

4. Attach the air pump or compressor hose to the air-control valve with a “tire valve” connection and

pressure gauge.

4. Pump up, or inate to the designated preliminary lling pressure. Preliminary lling pressure: 1.8 ~

2.0 bar

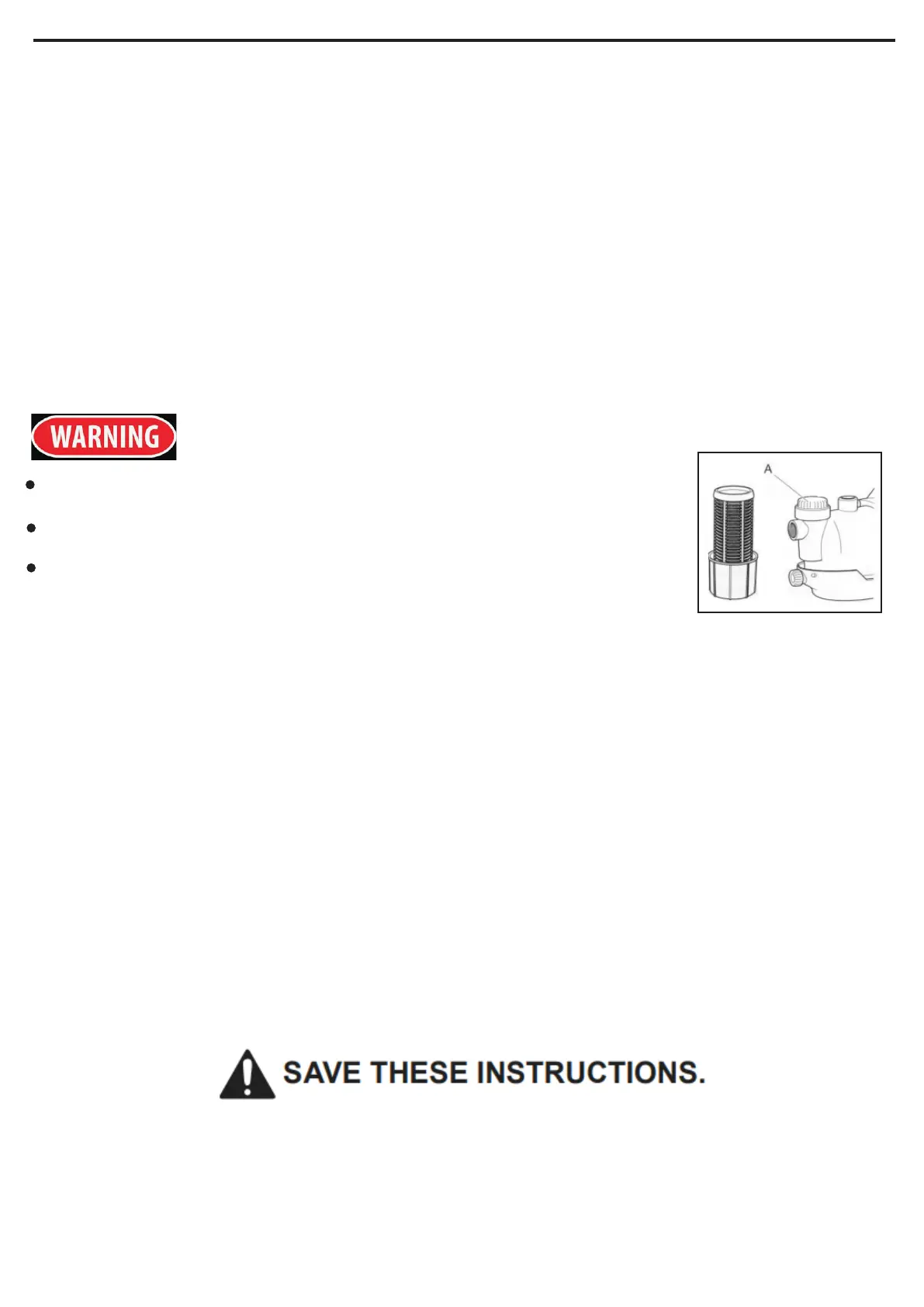

Unscrew lter housing (A) and take out the lter cartidge

If necessary, soak the cartridge in warm water

Rinse the lter cartidge with clean water, brush out stubborn dirt from inside

the cartridge using a soft brush.

DANGER: If the conveyed water is highly contaminated, clean the water after

each use. A clogged lter may damage the device.

6

STORAGE

If there is danger of frost, dismantle the device and accessories, clean and store them in a place

protected from frost.

1. Turn off the device and unplug the mains plug

2. Open pressure line, allow water to completely run off

3. Completely empty the pump and boiler

4. Dismantle the suction and pressure lines from the device

5. Store the device in a frost free room, at least 5 °C

Dismantling

Loading...

Loading...