26

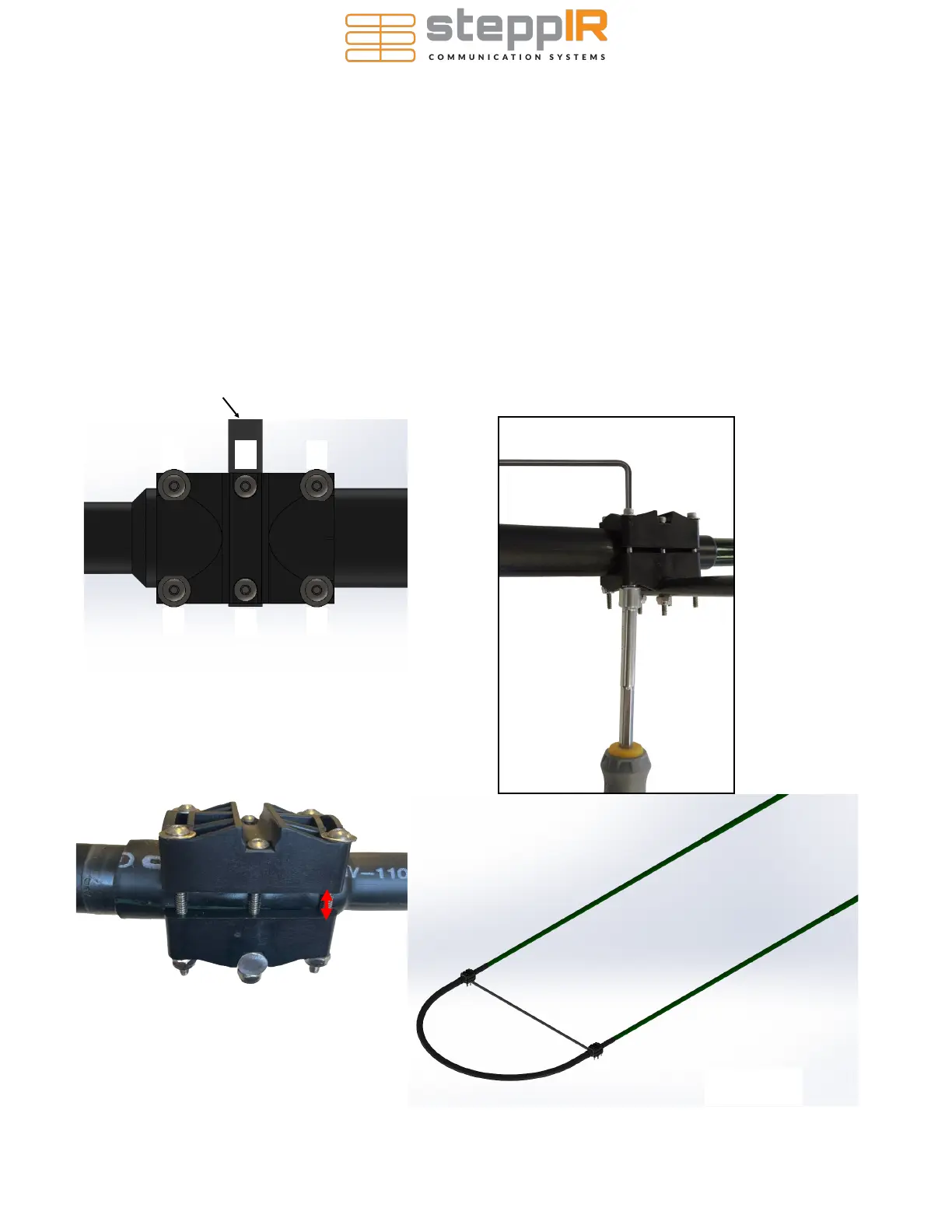

FINAL TIGHTENING

21. Finish tightening the four screws on the outside corners of the plastic coupler. Tighten evenly, in

an automobile X type pattern as shown in figure 6.14. If you do not tighten evenly, you may break

the fastener. Once the outsides are firmly tight, tighten the two screws that hold the fiberglass

spreader in place. Figure 6.15 shows the suggested method for tightening the screws.

22. When completely tightened, THE SWEEP COUPLER HALVES SHOULD HAVE GAP OF ABOUT 5/16”

– 3/8”, as shown in figure 6.16. This gap is not critical as the coupler is mostly to keep the spreader in

place properly. IT IS BEST TO LET THE SCREWS SIT FOR A WHILE (15-30MIN) AND TIGHTEN IN IN-

TERVALS IN ORDER TO ALLOW THE PLASTIC CLAMP MATERIAL TO RE-FORM. This also will reduce

the chance of snapping a screw.

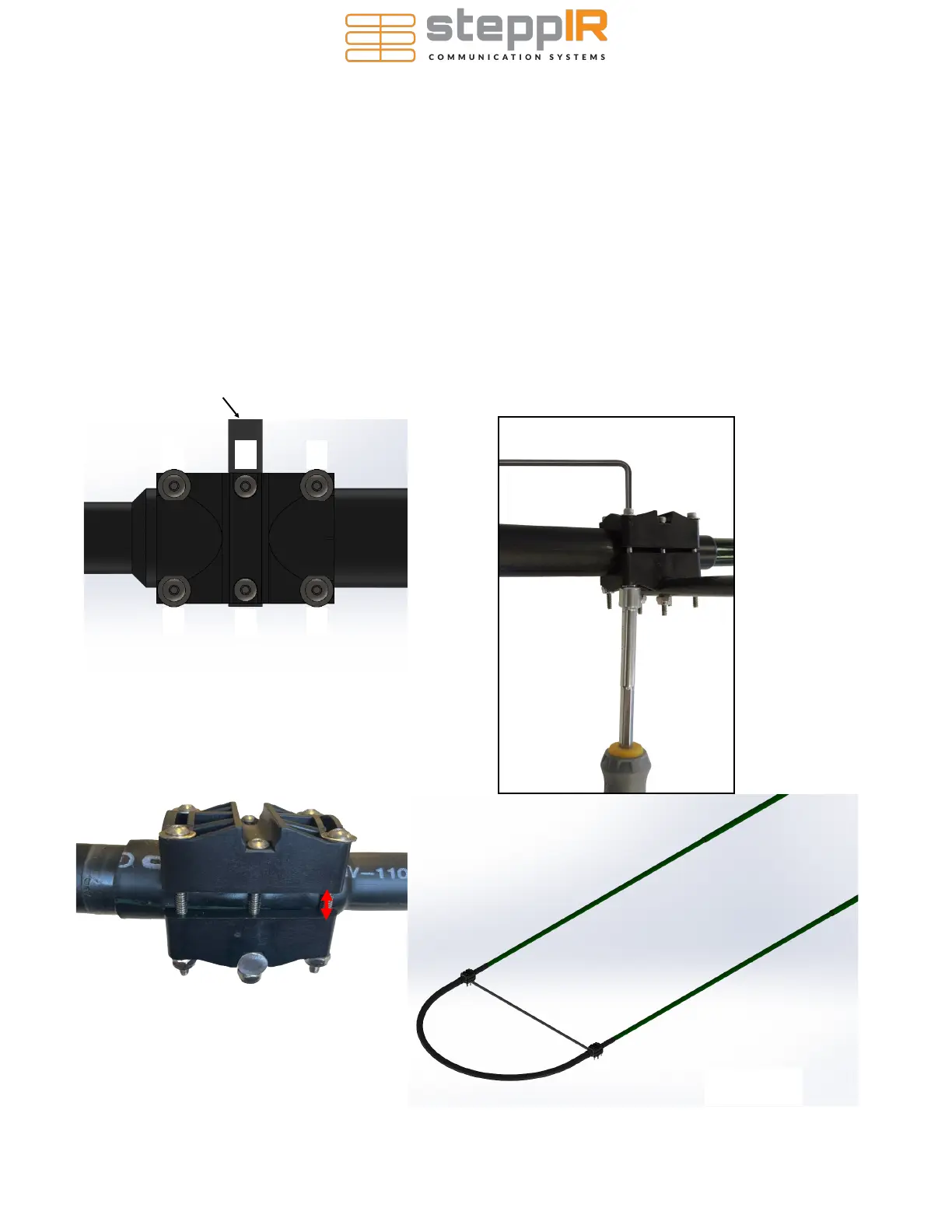

23. Figure 6.17 shows the completed sweep—repeat the process for each sweep.

FIG. 6.16

FIG. 6.17

FIG. 6.15

1

2 3

4

5

6

FIG. 6.14

5/16”

Fiberglass spreader rod

Loading...

Loading...