Release 00 - 03/2018

Engine TRE 0701-TRE 0702-TRE 0801

pag. 13

4. ENGINE TUNING AND TESTING

4.1. Operating guidelines

The engine requires a series of interventions (shown in the table below) in order to ensure minimum basic

maintenance.

Operation First 5 hours

Every 5 hours

or daily

Every 25

hours or

every season

Every 50

hours or

every season

Every 100

hours

Check oil level

- ■ - - -

Change oil *

(1)

■ - - - ■

Check and oil pre-lter *

(2)

- ■ - - -

Blow lter *

(2)

- - ■ - -

Check spark plug

- - - ■ -

Replace spark plug

- - - - ■

*

(1)

Replace the oil every 25 hours if the engine is working at full load or at high temperatures.

*

(2)

Clean the air lter more often if the machine is working in dusty areas.

For the operations that are not difcult for the nal

user the assistance centre must maintain the mo-

tor in perfect efciency, in accordance with two

intervention lines:

- Tuning the engine whenever possible.

- Recommending the client a routine maintenan-

ce program at set intervals (e.g. at the end of

the season or before a long period of inactivity).

4.2. Engine tuning program

As part of general engine tuning or any intervention

on the machine, it is recommended that the Service

Centre performs a series of operations aimed at

maintaining the engine’s efciency.

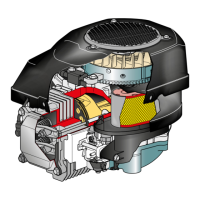

Tuning should involve:

- external blowing and cleaning the cylinder

head, cylinder and mufer by removing any

remains of grass and mud;

- checking the oil level, topping up or replacing

parts if necessary;

- cleaning the air lter [

5.1];

- adjusting minimum and maximum speeds [

7.3 and 8.4];

- inspecting the condition of the spark plug; che-

cking the distance between the electrodes [

9.1];

- tightening the screws [

11.2];

- functional test [ 4.3].

Should the checks and adjustments fail to achieve

a satisfactory result, refer to chapter [ 14] for

troubleshooting.

Loading...

Loading...