pag. 42

Engine TRE 0701-TRE 0702-TRE 0801

Service manual

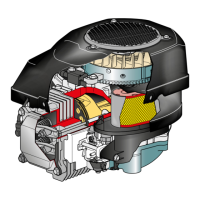

10. ENGINE BLOCK – External repairs

10.9. Replacingthelowercompressionringofthe

engine shaft (sump side)

NOTE - Before executing this operation di-

scharge all the oil from the bowl and rotate

180° the motor.

1 - Take out the spline key (49).

2 - Use a thin screwdriver inserted under the sealing

lip to extract the oil seal ring (50).

3 -Make a paper tube (51) around the shaft to

protect the sealing lip and insert the new ring (52)

so that it enters its housing.

4 - Complete the insertion with the help of a pipe

(53) of a diameter of approximately 30-35 mm.

Tightening torques

2 Spark plug tightening torque 18-22 Nm

6 Valve cover xing screws 8-12 Nm

15 Cylinder head screws 50-55 Nm

32 Flywheel xing nut 110-120 Nm

39 Screws small plate louver 8-12 Nm

43 Screws alternator xage 8-12 Nm

Technical information

Compression 4.2 bar

Inlet valve clearance 0.10-0.15 mm

Exhaust valve clearance 0.15-0.20 mm

Minimum inlet valve stem diameter 6.425 mm

Minimum exhaust valve stem

diameter

6.375 mm

Min. inlet valve head rim thickness

(TRE 0701- TRE 0702)

(TRE 0801)

0.5 mm

0.8 mm

Min. exhaust valve head rim thickness

1.0 mm

Valve seat depth 1.5 mm

Minimum valve spring length 37.5 mm

Alternator charge 3.0-4.0 Ω

Special equipment

3 Compression testing tool

29 Valve seat grinding tool

30 Valve grinder

49

50

52

51

53

Loading...

Loading...