- 25 -

4. MAINTENANCE

4.2 MAINTENANCE

4.2.1 Engine

All engines operate at 3400 RPM.

Thoroughly service engine at least annually.

Follow manufacturers recommendations

including: clean carbon from cylinder head,

check intake and exhaust valves, clean and

adjust carburetor, check ignition cable and daily

check for damaged parts and replace. Check

for loose fasteners - tighten as per torque chart.

4.2.2 Engine Oil

Check engine oil level daily. Consult engine

manual included with this unit for specific

maintenance instructions.

4.2.3 Air Filter

Remove foam pre-cleaner from air filter daily.

Wash the foam in liquid detergent and water.

Squeeze dry between towels. Oil with one

ounce of engine oil and squeeze to distribute oil

evenly. Units equipped with Wisconsin Robin

engines, use kerosene in place of oil and

squeeze excess from foam. Keeping the filter

clean prolongs the engine life and decreases

fuel consumption.

4.2.4 Eccentric Oil

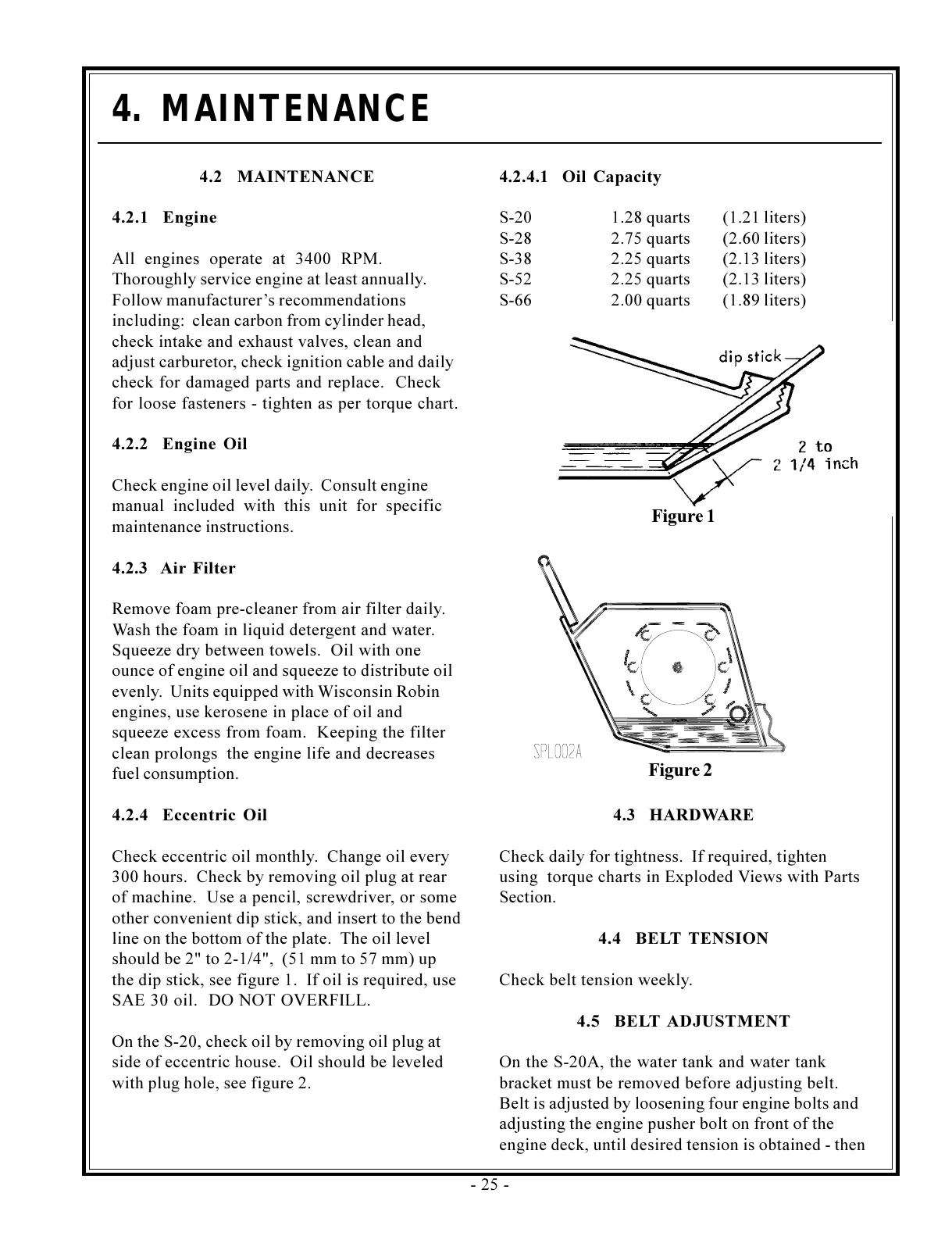

Check eccentric oil monthly. Change oil every

300 hours. Check by removing oil plug at rear

of machine. Use a pencil, screwdriver, or some

other convenient dip stick, and insert to the bend

line on the bottom of the plate. The oil level

should be 2" to 2-1/4", (51 mm to 57 mm) up

the dip stick, see figure 1. If oil is required, use

SAE 30 oil. DO NOT OVERFILL.

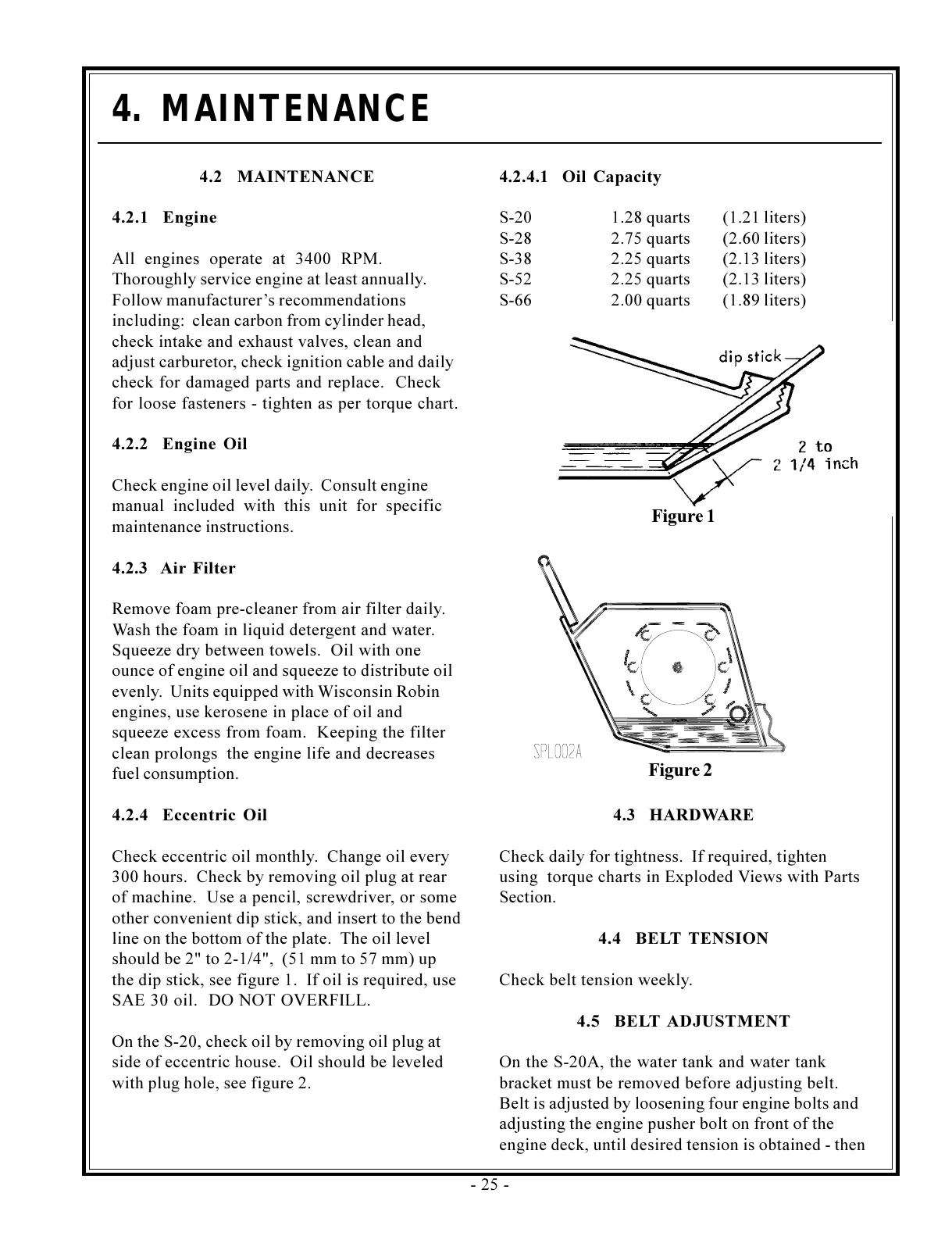

On the S-20, check oil by removing oil plug at

side of eccentric house. Oil should be leveled

with plug hole, see figure 2.

4.2.4.1 Oil Capacity

S-20 1.28 quarts (1.21 liters)

S-28 2.75 quarts (2.60 liters)

S-38 2.25 quarts (2.13 liters)

S-52 2.25 quarts (2.13 liters)

S-66 2.00 quarts (1.89 liters)

4.3 HARDWARE

Check daily for tightness. If required, tighten

using torque charts in Exploded Views with Parts

Section.

4.4 BELT TENSION

Check belt tension weekly.

4.5 BELT ADJUSTMENT

On the S-20A, the water tank and water tank

bracket must be removed before adjusting belt.

Belt is adjusted by loosening four engine bolts and

adjusting the engine pusher bolt on front of the

engine deck, until desired tension is obtained - then

Figure 1

Figure 2

Loading...

Loading...