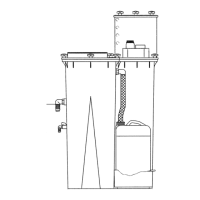

SECTION 2 OIL WATER SEPARATOR

15

2.14 TECHNICAL INFORMATION

ON THE OIL-WATER

SEPARATOR

From time to time problems occur which require a

more detailed knowledge of the OWS. Below are

some information and rules which will help you.

2.15 OPERATING INSTRUCTION

Please read all instructions carefully , especially the

paragraph “condensate flow rate“, and be sure to

comply with it. The condensate should be fed

automatically, when possible; input under pressure is

possible by means of the expansion nozzle the

device is equipped with.

2.16 INFLUENCE OF THE

COMPRESSOR OIL ON THE

EFFICIENCY

In the past compressor oils were only chosen to suit

the compressor. The problem of the condensate

disposal was hardly considered or completely

neglected. This is why many companies still use

compressor oils which emulsify strongly with water

and some of which form stable emulsion.

Table 2-4: Capacity of OWS - Oil Water Separators in cfm of installed compressor-capacity

Type of Compressor Screw-Compressor

OWS Model OWS-88 OWS-210 OWS-420 OWS-880 OWS-1700 OWS-2100

non emulsified oils 88 210 420 880 1700 2100

Rotation-Compressor (oil-flooded)

OWS Model OWS-88 OWS-210 OWS-420 OWS-880 OWS-1700 OWS-2100

non emulsified oils 88 210 420 880 1700 2100

Piston Compressor (1 and 2 stage)

OWS Model OWS-88 OWS-210 OWS-420 OWS-880 OWS-1700 OWS-2100

non emulsified oils 44 100 200 440 800 1000

NOTE

1. The capacity above are maximum

figures.

2. Reduce the capacity when the

OWS is installed in difficult condi-

tions (e.g. hot dirty, dusty condi-

tions).

3. Divide capacity by 2 for conden-

sate delivered through timed sole-

noid drains.

Loading...

Loading...