Section 2

ShopTek™ ST4, ST5, ST7, ST11, ST15 Three-phase 60 Hz User Manual 2: Description

88292018-236 R00

Subject to EAR, ECCN EAR99 and related export control restrictions. 9

Description

2.1 Introduction

The design of the Sullair ShopTek line of compressor

units is a single stage, positive displacement, flooded

rotary screw. A complete package includes the:

• Compressor unit

•

Electric motor

•Starter

• Compressor inlet and discharge systems

• Compressor lubrication and cooling system

• Controller

• Aftercooler (ST11 and ST15 only)

• Heavy gauge steel mounting frame

New compressors are shipped from the factory fully

charged with

Sullube

®

lubrication fluid. Section 3.2 and

Section 3.3 describe lubrication requirements and recom-

mendations for each c

ompressor package.

External piping, connectors, an

d the enclosure should be

inspected and maintained in accordance with the proce-

dures and recommendations in this manual.

2.2 Compressor component

description

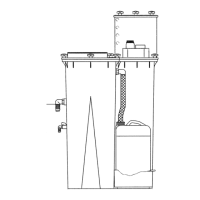

The ShopTek compressor (Figure 2-1 and Figure 2-2)

uses a fan to draw outside air into the enclosure, cooling

the

motors, the combined radiator fluid cooler, and air

aftercooler. This hot air is then vented out of the top of

the enclosure.

Fluid is injected into the compressor, and mixes directly

with

the air as the rotors turn which compresses the air.

The fluid flow has three basic functions:

• As a coolant, it controls the air temperature rise

no

rmally associated with the heat of compres-

sion.

• Seals the clearance paths between the rotors

and the stator, and also between the two rotors.

• Provides a lubricating film between the rotors

allowing one rotor to directly drive the other,

which is an idler, and also lubricates the bearings.

After the air/fluid mixture is discharged from the compres-

sor unit, the fluid is separated from the air. At this time,

the

air flows through an aftercooler and separator, and

then to the service line while the fluid is cooled and fil-

tered in preparation for reinjec

tion.

CAUTION

Use only one type of a recommended compres-

sor lubricant. Adding a different one, or mixing

lubricants can cause damage and/or malfunc-

tions, and will void the compressor’s warranty.

NOTE

The compressor air end requires no internal

inspections or maintenance actions. Opening

the compressor air end’s housing may void its

warranty. (This does not apply to the shaft seal

or inlet valve which are replaceable.)

Loading...

Loading...