ensure minimum removal of material and even sharpness on all the cutting

edges.

If you sharpen the chain yourself, use special round-section files with the right

diameter depending on the type of chain (see "Chain Maintenance Table").

You need a certain amount of skill and experience to avoid damaging the

cutting edges.

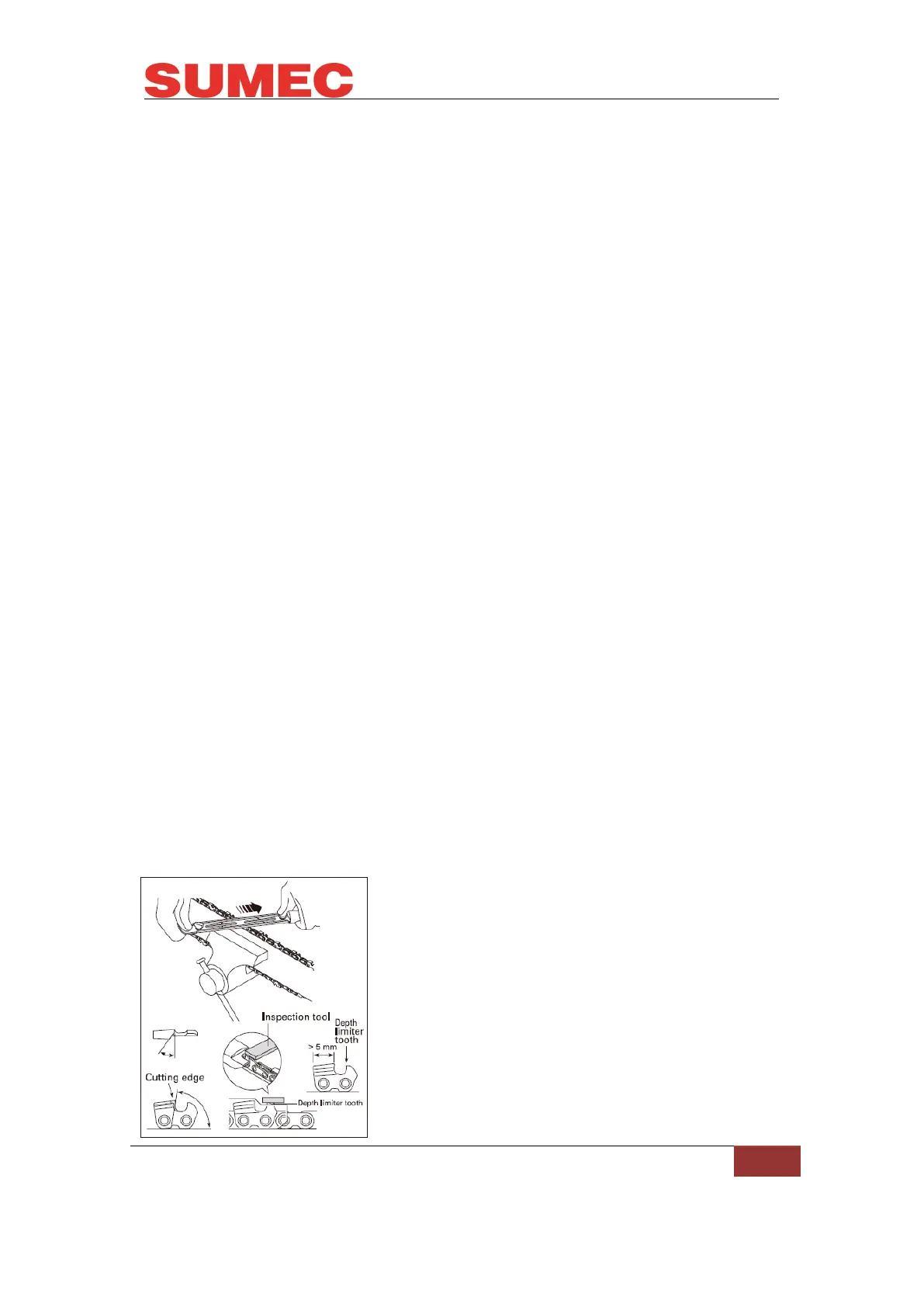

Sharpen the chain as follows (Fig. 17):

• Secure the bar firmly, with the chain mounted, in a suitable vice.

• Tighten the chain if it is loose.

• Mount the file in the guide and then insert it in the tooth at a constant angle

from the cutting edge.

• Sharpen in a forward motion a few times and repeat this on all the cutting

edges facing the same way (right or left).

• To move the chain forward, use a screwdriver.

• Turn the bar over in the vice and repeat on all the other cutting edges.

• Check that the depth limiter tooth does not stick out farther than the

inspection tool and file any projecting parts with a flat file, rounding off the

edges (Fig. 17).

• After sharpening, remove all traces of filing and dust and lubricate the chain

in an oil bath. Replace the chain whenever:

- The length of the cutting edges decreases to 5 mm or less;

- There is too much play between the links and the rivets.

Loading...

Loading...