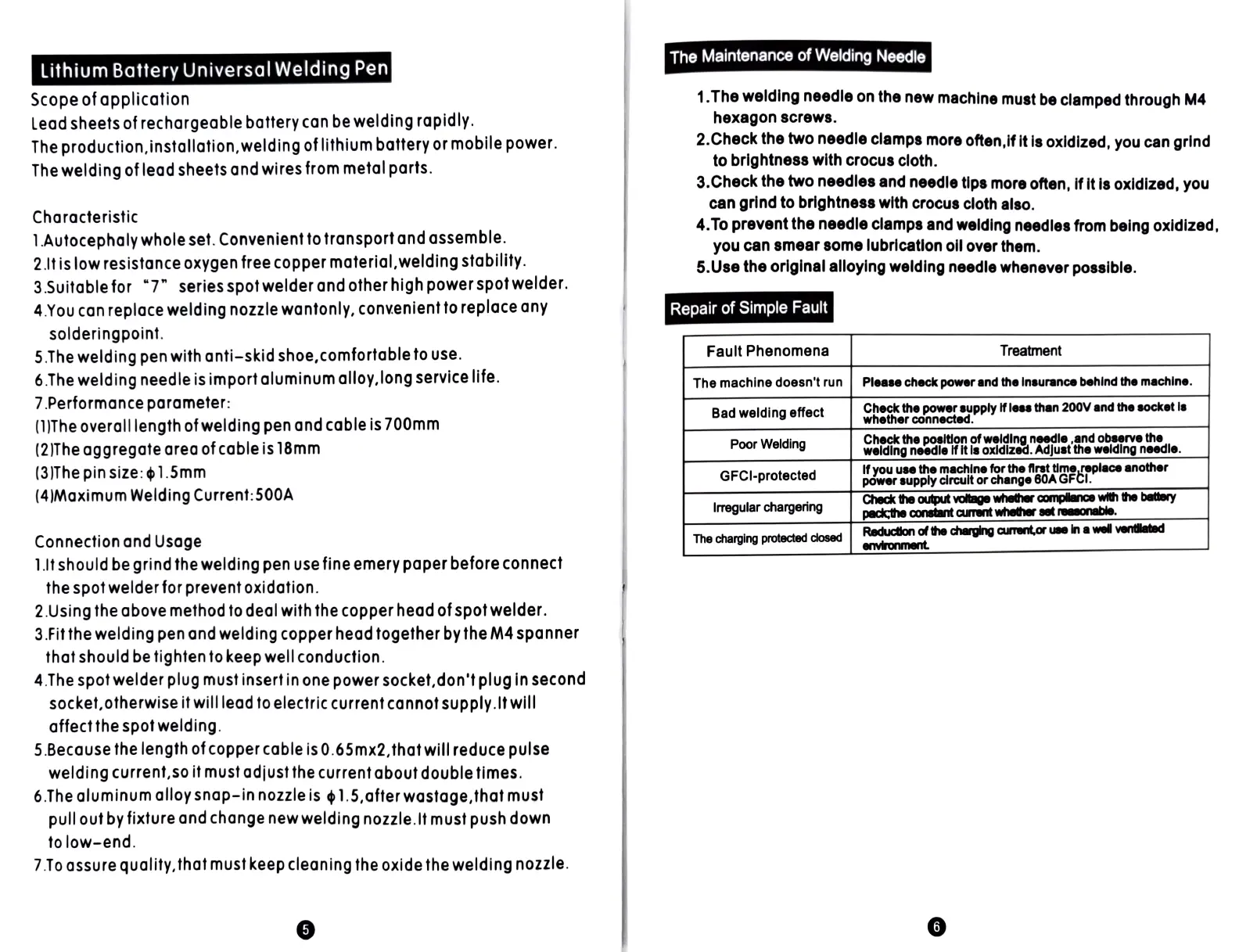

The

Maintenance

of

Welding

Needle

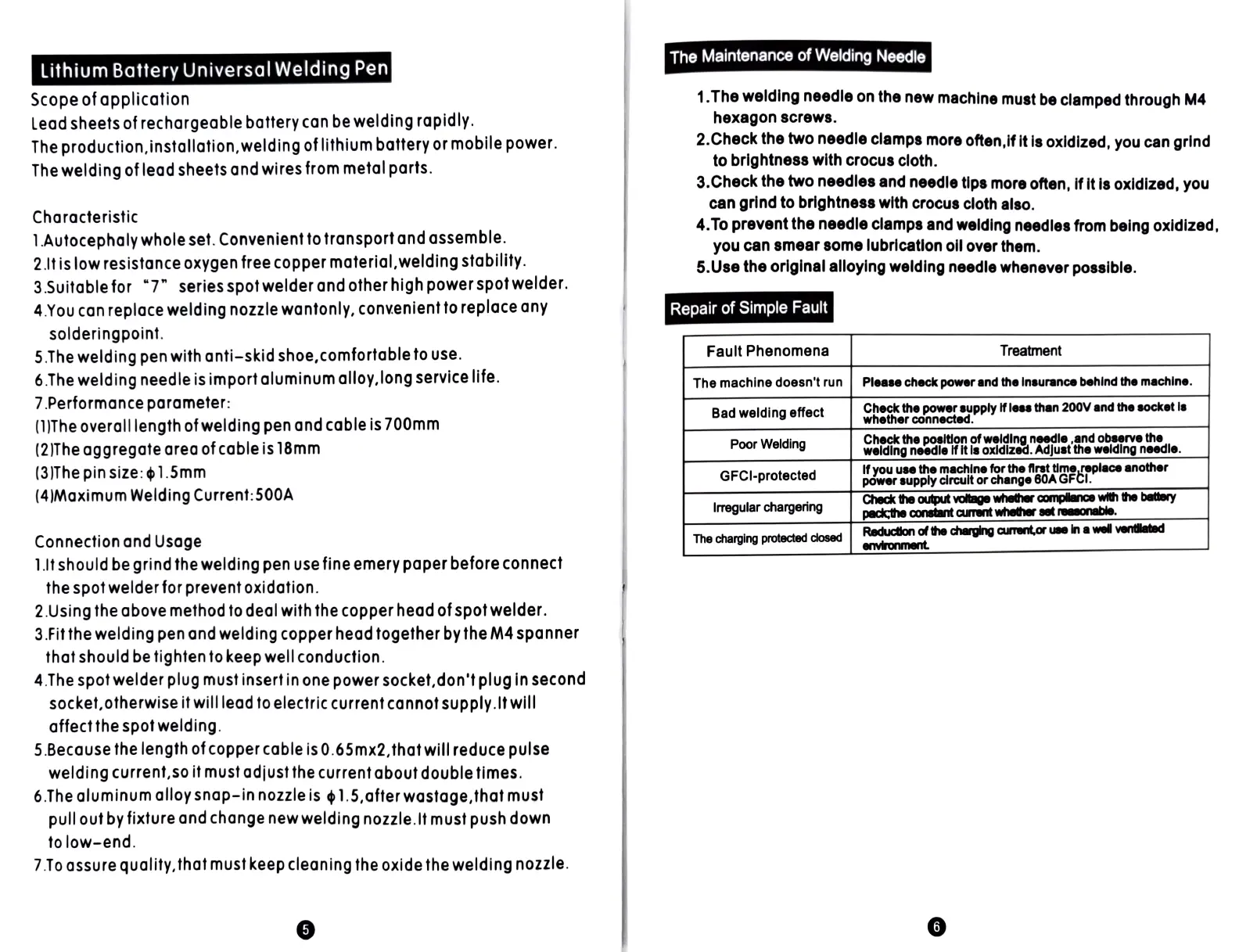

Lithium

Battery

Universal

Welding

Pen

1.The

welding

needle

on

the

new

machine

must

be

clamped

through

M4

hexagon

screws.

2.Check

the

two

needle

clamps

more

often,

if

it

is

oxlidized,

you

can

grind

to

brightness

with

crocus

cloth.

3.Check the two needles

and

needle

tips

more

often,

If

itis

oxidized,

you

can

grind

to

brightness

with

crocus

cloth

also.

4.To

prevent

the

needle

clamps

and

welding

needles

from

being

oxidized,

you

can

smear

some

lubrication oil

over

them.

5.Use

the

orlginal alloying

welding

needle

whenever

possible.

Scope

of

application

Lead

sheets

of

rechargeable battery can

be

welding rapidly.

The

production,

installation,

welding

of

lithium

battery

or

mobile

power.

The welding of lead

sheets

and wires from metal parts.

Characteristic

1Autocephaly

whole

set.

Convenient

to

transport

and

assemble.

2.lt

is

low

resistance

oxygen

free

copper material,welding stability.

3.Suitable

for

*7"

series

spot

welder and other

high

power

spot

welder.

4.You

can replace welding nozzle wantonly, convenient to replace any

Repair

of

Simple

Fault

solderingpoint.

5.The

welding

pen

with

anti-skid

shoe,comfortable

to

use.

6.The welding needle

is

import aluminum alloy,long service life.

Fault

Phenomena

Treatment

The

machine

doesn't

run

Please

check

power

and

the

Insurance

behind

thee

machine.

7.Performance parameter:

(The

overall length ofwelding pen

and

cable

is

700mm

(2)The

aggregate

area

of

cable

is

18mm

131The

pin

size:

1.5mm

Check

the

power

supply

If

less

than

200oV

and

the

socket

is

whether

connected.

Check

the

posltlon

of

welding

needle.and

observe

the

welding

needle

If

it

is

oxldlzed.

Adjust

the

welding

needle.

If

you

use

the

machine

for

the

firet

time.replace

another

powor

supply

clrcult

or

change

60A

GFCl.

Check

the

output

voltage

whether

compllence

with

the

betery

peckthe

constant

curent

whether

set

reesonable

Reduction of

the

chergling cument,or

use

in

a well ventdlated

environment

Bad welding effect

Poor Welding

GFCl-protected

(4)Maximum Welding Current:500A

Irregular

chargering

Connection

and

Usage

1.1t

should

be

grind

the

welding

pen

use

fine

emery

paper before connect

the spot welder

for

prevent oxidation.

2.Using the above method

to

deal with the

copper

head

of

spotwelder.

3.Fit

the welding pen and welding copper

head

together

by

the

M4

spanner

that

should be tighten to keep well conduction.

4.The

spot welder

plug

must

insert

in

one

power

socket,don't

plug

in

second

socket,otherwise

it

will

lead

to

electric currentcannotsupply.lt

will

affect

the

spot

welding.

5.

Because

the length of copper cable

is

0.65mx2,that

will

reduce pulse

welding current,so

it

must adjust the current

about

double times.

6.The

aluminum

alloy

snap-in

nozzle

is

$1.5,after wastage,that

must

pull

out

byfixture

and

change

new

welding

nozzle.lt

must

push

down

The charging protected closed

to

low-en.

7.To

assure

quality.that must keep cleaning the oxide the welding nozzle.

5

6

Loading...

Loading...