esr->0

..

suRGE

..,.,....,.rgy

i

n

t

e

I I

i

g

e

n

c

e

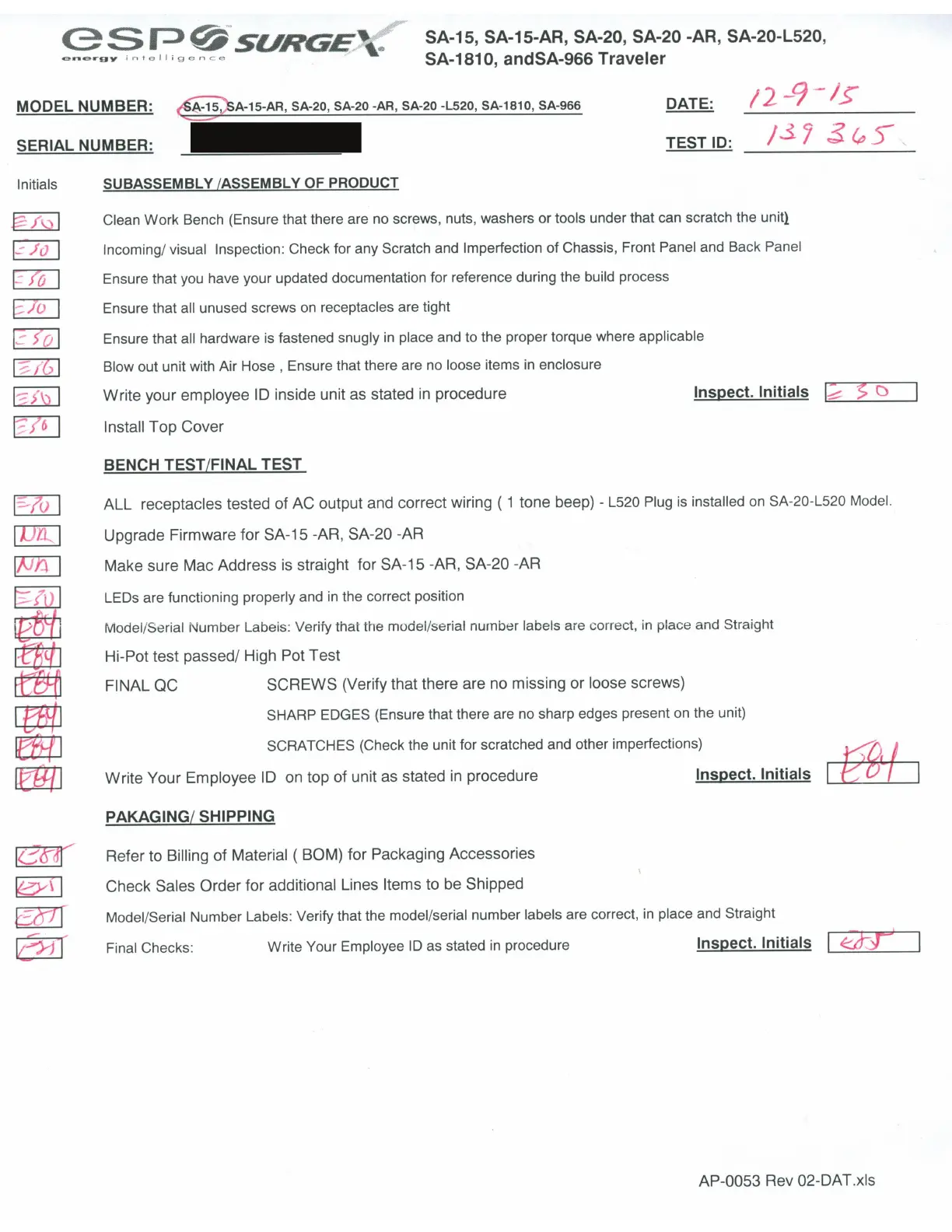

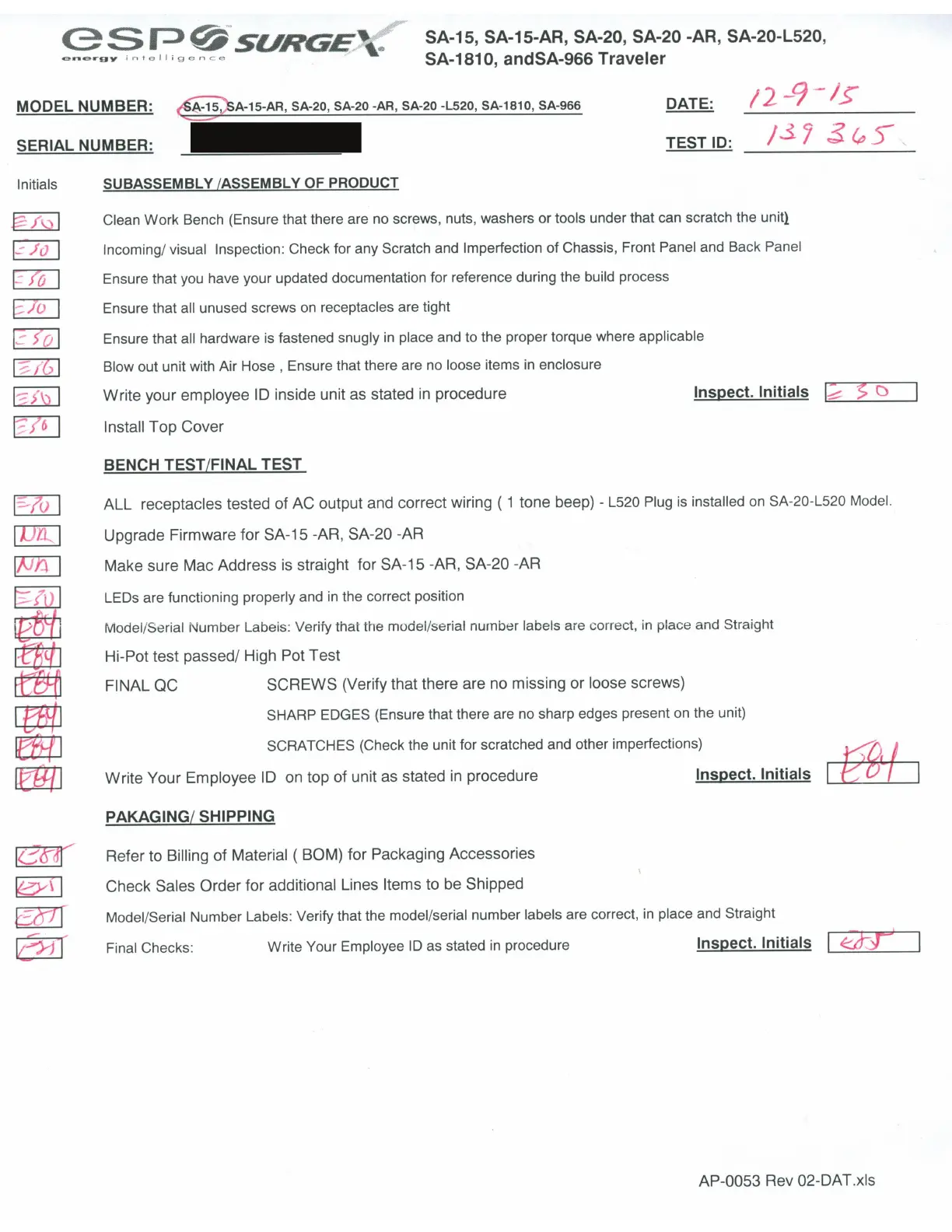

SA-15, SA-15-AR,

SA-20, SA-20

-AR, SA-20-L520,

SA-181

0,

andSA-966

Traveler

MODEL NUMBER:

DATE:

i2-

SERIAL

NUMBER:

TEST ID:

J3.7~~s-

,

Initials

gAl]

1-

Ju

I

1-

>o

I

~

I

~

>o

l

l

-t

61

l

?l\)

I

rL!J

1

~/o

I

lt

tn

I

~

I

SUBASSEMBLY/ASSEMBLY

OF

PRODUCT

Clean

Work Bench (Ensure that there are no screws, nuts, washers or

tools

under that can scratch the unitl

Incoming/ visual Inspection:

Check for any Scratch and Imperfection of Chassis, Front Panel

and Back

Panel

Ensure that you have your updated documentation for reference during the

build

process

Ensure that

all

unused screws

on

receptacles

are tight

Ensure that

all

hardware is fastened

snugly

in

place

and to the proper torque where

applicable

Blow

out unit with Air Hose , Ensure that there are no

loose

items

in

enclosure

Write your

employee

10

inside unit as stated

in

procedure

Install

Top

Cover

BENCH

TEST /FINAL TEST

Inspect.

Initials

I

~

>

D

I

ALL

receptacles

tested of AC output and correct wiring (

1 tone beep) -

L520 Plug is

installed

on

SA-20-L520 Model.

Upgrade Firmware for SA-15 -AR, SA-20 -AR

Make sure Mac Address

is

straight for SA-15 -AR, SA-20 -AR

LEOs

are functioning

properly

and

in

the correct position

Model/Serial Number Labeis: Verify that

the model/serial number

labels

are correct,

in

place

and Straight

Hi-Pot test passed/ High Pot Test

FINAL QC SCREWS (Verify that there are no missing or

loose

screws)

SHARP EDGES (Ensure that there are no sharp edges present

on

the unit)

SCRATCHES (Check the unit for scratched and other imperfections)

Write Your

Employee

10

on

top of unit as stated

in

procedure

PAKAGING/ SHIPPING

Refer to

Billing

of

Material

(

BOM)

for Packaging Accessories

Check Sales Order

for additional

Lines

Items

to be Shipped

Inspect.

Initials

Model/Serial Number

Labels:

Verify that the

model/serial

number

labels

are correct,

in

place

and Straight

Final Checks:

Write

Your

Employee

ID

as stated

in

procedure

Inspect. Initials

AP-0053

Rev 02-DAT

.xis

Loading...

Loading...