Performance Check Procedure-2225 Service

TRIGGER

Equipment Required (See Table 4-1):

Leveled Sine-Wave Generator (Item 2) Dual-Input Coupler (Item

9)

Low-Frequency Sine-Wave Generator (Item 4) 50-CI BNC Termination (Item 10)

50-il BNC Coaxial Cable (Item

8)

600-CI BNC Termination (Item

11

)

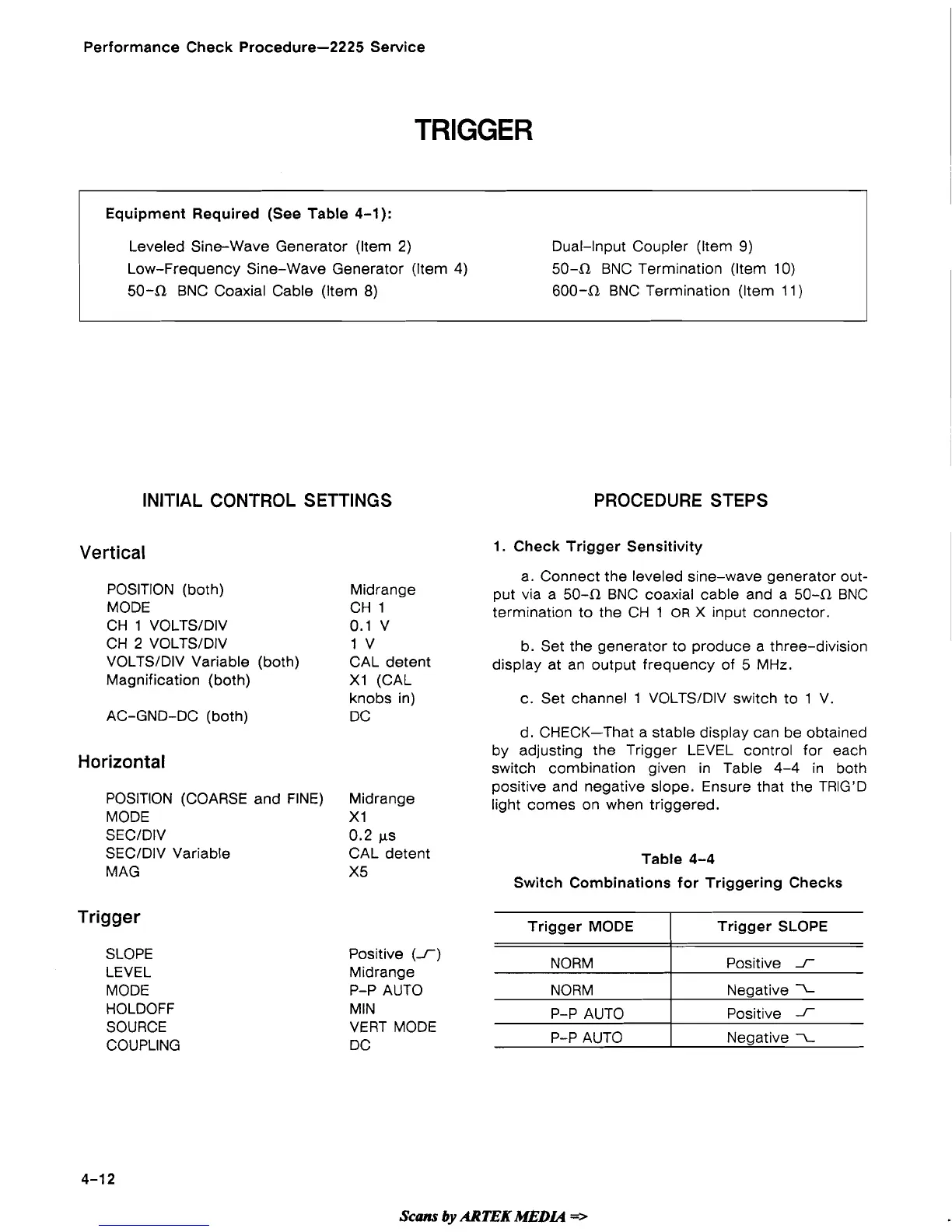

INITIAL CONTROL SETTINGS

Vertical

POSITION (both) Midrange

MODE

CH 1

CH 1

VOLTSIDIV 0.1 V

CH 2

VOLTSIDIV

1

V

VOLTSIDIV Variable (both) CAL detent

Magnification (both)

Xl (CAL

knobs in)

AC-GND-DC (both) DC

Horizontal

POSITION (COARSE and FINE) Midrange

MODE

XI

SECIDIV 0.2 ~s

SECIDIV Variable CAL detent

MAG X5

Trigger

SLOPE

LEVEL

MODE

HOLDOFF

SOURCE

COUPLING

Positive

(I)

Midrange

P-P AUTO

MIN

VERT MODE

DC

PROCEDURE STEPS

1.

Check Trigger Sensitivity

a. Connect the leveled sine-wave generator out-

put via a

50-CI BNC coaxial cable and a 504 BNC

termination to the CH

1

OR

X

input connector.

b. Set the generator to produce a three-division

display at an output frequency of 5 MHz.

c. Set channel 1 VOLTSIDIV switch to

1

V

d.

CHECK-That a stable display can be obtained

by adjusting the Trigger LEVEL control for each

switch combination given in Table 4-4 in both

positive and negative slope. Ensure that the TRIG'D

light comes on when triggered.

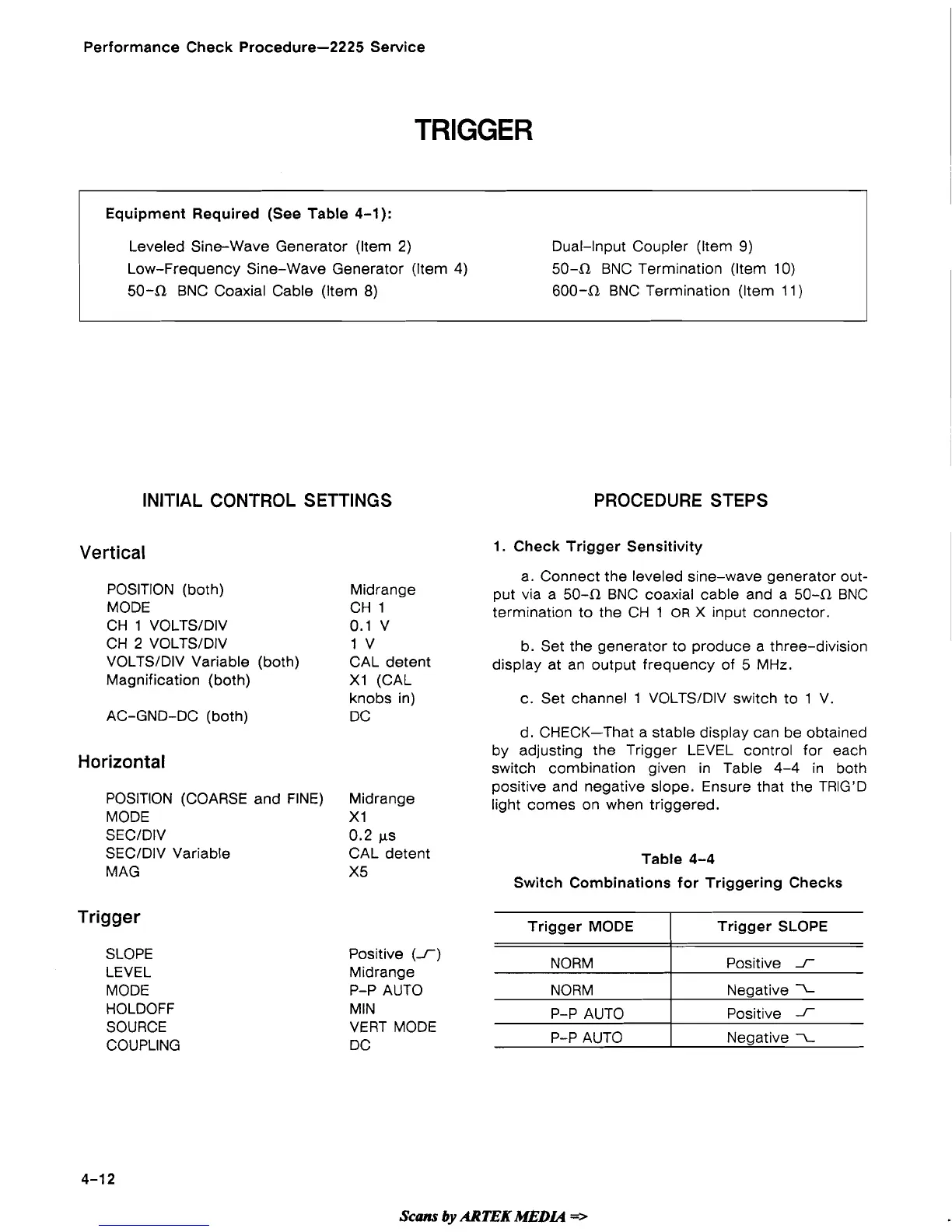

Table 4-4

Switch Combinations for Triggering Checks

Scans

by

ARTEK

MEDL4

=>

Trigger MODE

NORM

NORM

P-P AUTO

P-P AUTO

Trigger SLOPE

Positive

f

Negative

7-

Positive

f

Negative

x

Loading...

Loading...