Maintenance-2225 Service

Table

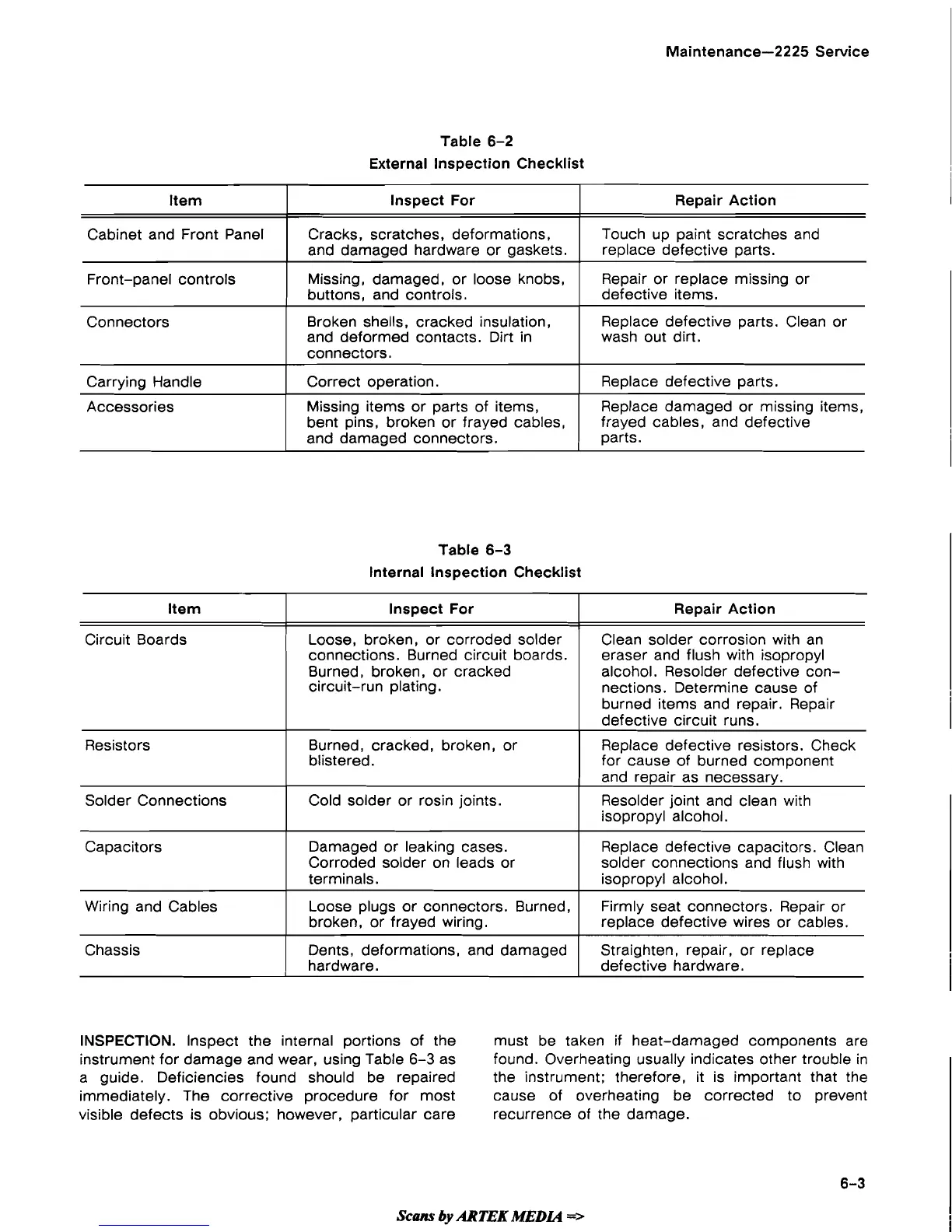

6-2

External lnspection Checklist

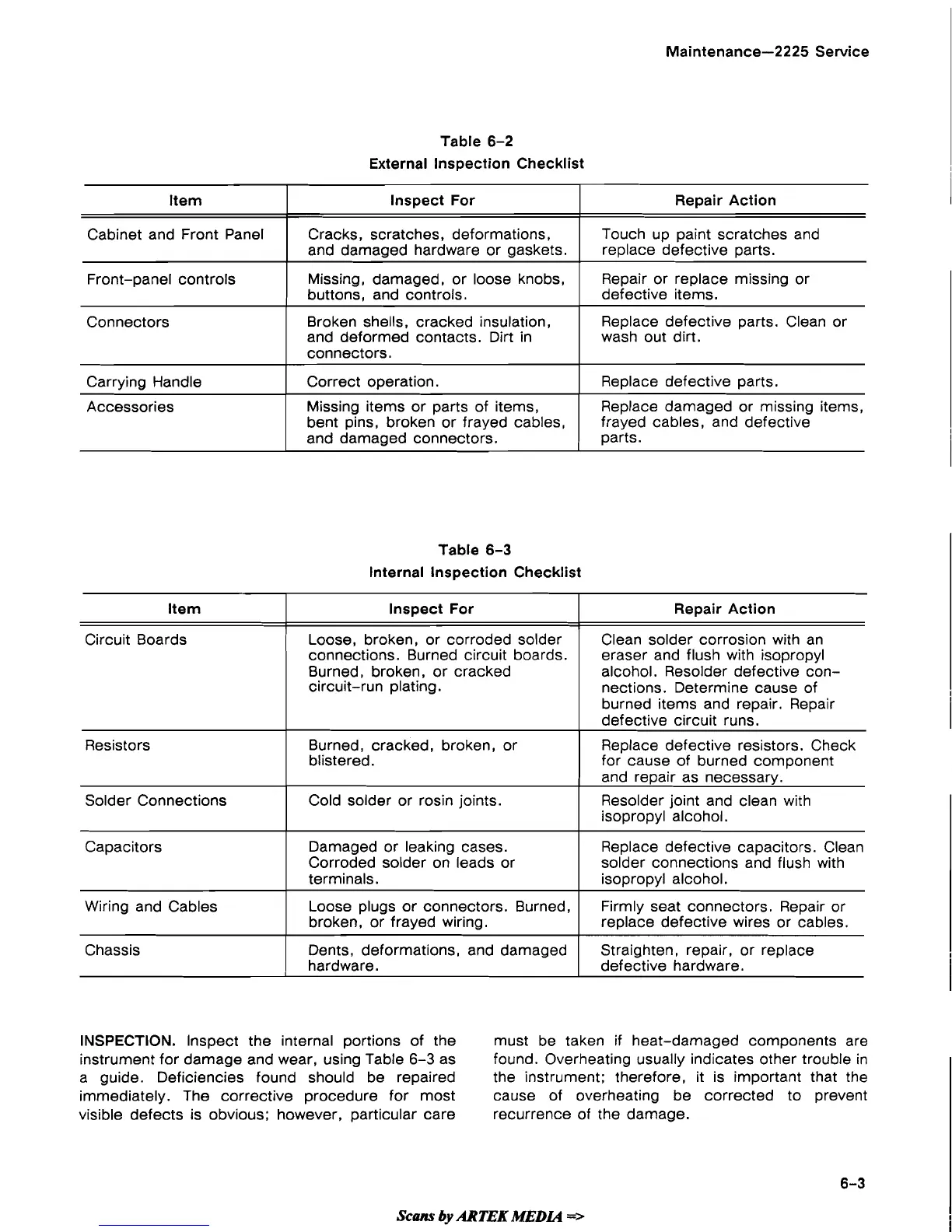

Table

6-3

Internal Inspection Checklist

Repair Action

Touch up paint scratches and

replace defective parts.

Repair or replace missing or

defective items.

Replace defective parts. Clean or

wash out dirt.

Replace defective parts.

Replace damaged or missing items,

frayed cables, and defective

parts.

Item

Cabinet and Front Panel

Front-panel controls

Connectors

Carrying Handle

Accessories

INSPECTION. Inspect the internal portions of the must be taken if heat-damaged components are

instrument for damage and wear, using Table

6-3

as found. Overheating usually indicates other trouble in

a guide. Deficiencies found should be repaired the instrument; therefore, it is important that the

immediately. The corrective procedure for most cause of overheating be corrected to prevent

visible defects is obvious; however, particular care

recurrence of the damage.

Inspect For

Cracks, scratches, deformations,

and damaged hardware or gaskets.

Missing, damaged, or loose knobs,

buttons, and controls.

Broken shells, cracked insulation,

and deformed contacts. Dirt in

connectors.

Correct operation.

Missing items or parts of items,

bent pins, broken or frayed cables,

and damaged connectors.

Item

Circuit Boards

Resistors

Solder Connections

Capacitors

Wiring and Cables

Chassis

Scans

by

ARTEK

MEDLA

=>

Inspect For

Loose, broken, or corroded solder

connections. Burned circuit boards.

Burned, broken, or cracked

circuit-run plating.

Burned, cracked, broken, or

blistered.

Cold solder or rosin joints.

Damaged or leaking cases.

Corroded solder on leads or

terminals.

Loose plugs or connectors. Burned,

broken, or frayed wiring.

Dents, deformations, and damaged

hardware.

Repair Action

Clean solder corrosion with an

eraser and flush with isopropyl

alcohol.

Resolder defective con-

nections. Determine cause of

burned items and repair. Repair

defective circuit runs.

Replace defective resistors. Check

for cause of burned component

and repair as necessary.

Resolder joint and clean with

isopropyl alcohol.

Replace defective capacitors. Clean

solder connections and flush with

isopropyl alcohol.

Firmly seat connectors. Repair or

replace defective wires or cables.

Straighten, repair, or replace

defective hardware.

Loading...

Loading...