Maintenance-2225 Service

Voltage levels may be measured either with a DMM or

A defective component elsewhere in the instrument

with an oscilloscope. Voltage ripple amplitudes must can create the appearance of a power-supply

be measured using an oscilloscope. Before checking problem and may also affect the operation of other

power-supply circuitry, set the INTENSITY control to

circuits.

normal brightness, the

SECIDIV switch to 0.1 ms, the

Trigger MODE to

P-P

AUTO, and the Vertical MODE

7.

Check Circuit Board Interconnections.

switch to CH

1.

After the trouble has been isolated to a particular

circuit, again check for loose or broken connections,

When measuring ripple, use a

1X probe. The ripple

values listed are based on a system limited in

improperly seated semiconductors, and

heat-

bandwidth to 30 kHz. Using a system with wider

damaged components.

bandwidth will result in

higher readings.

8.

Check Voltages and Waveforms.

If the power-supply voltages and ripple are within the

Often the defective component can be located by

ranges listed in Table 6-4, the supply can be checking circuit voltages or waveforms. Typical

assumed to be working correctly. If they are outside voltages are listed on the schematic diagrams.

the range, the supply may be either misadjusted or Waveforms indicated on the schematic diagrams by

operating incorrectly. Use the Power Supply and CRT hexagonal-outlined numbers are shown adjacent to

Display subsection in the Adjustment procedure to the diagrams. Waveform test points are shown on the

adjust the -8.6-V supply. circuit board illustrations.

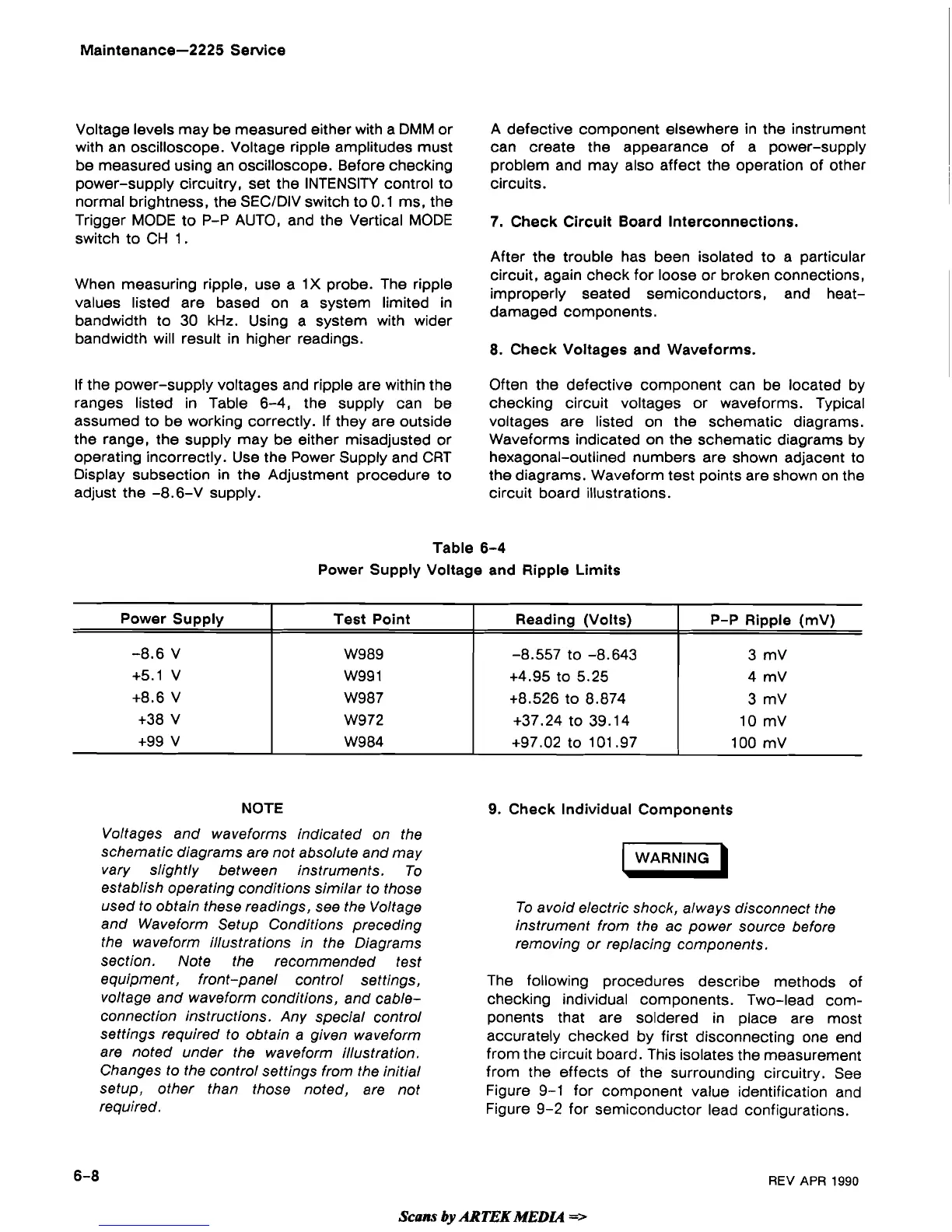

Table

6-4

Power Supply Voltage and Ripple Limits

NOTE

Power Supply

-8.6 V

+5.1 V

+8.6 V

+38 V

+99 V

Voltages and waveforms indicated on the

schematic diagrams are not absolute and may

vary slightly between instruments. To

establish operating conditions similar to those

used to obtain these readings, see the Voltage

and Waveform Setup Conditions preceding

the waveform illustrations in the Diagrams

section. Note the recommended test

equipment, front-panel control settings,

voltage and waveform conditions, and

cable-

connection instructions. Any special control

settings required to obtain a given waveform

are noted under the waveform illustration.

Changes to the control settings from the initial

setup, other than those noted, are not

required.

9.

Check Individual Components

Test Point

W989

W99 1

W987

W972

W984

WARNING

)

To avoid electric shock, always disconnect the

instrument from the ac power source before

removing or replacing components.

Reading (Volts)

-8.557

to -8.643

+4.95 to 5.25

+8.526 to 8.874

+37.24 to 39.14

+97.02 to 101.97

The following procedures describe methods of

checking individual components. Two-lead com-

ponents that are soldered in place are most

accurately checked by first disconnecting one end

from the circuit board. This isolates the measurement

from the effects of the surrounding circuitry. See

Figure 9-1 for component value identification and

Figure 9-2 for semiconductor lead configurations.

P-P Ripple

(mV)

3 mV

4

mV

3 mV

10 mV

100 mV

REV

APR

1990

Scam

by

ARTEK

MEDU

=>

Loading...

Loading...